Color-changing and multi-colored electroluminescent cable

a multi-colored, electroluminescent cable technology, applied in the direction of instruments, discharge tubes, luminescnet screens, etc., can solve the problems of high power consumption, high manufacturing and maintenance costs, and restricted freedom of shaping, and achieve the effect of low electricity consumption and convenient us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

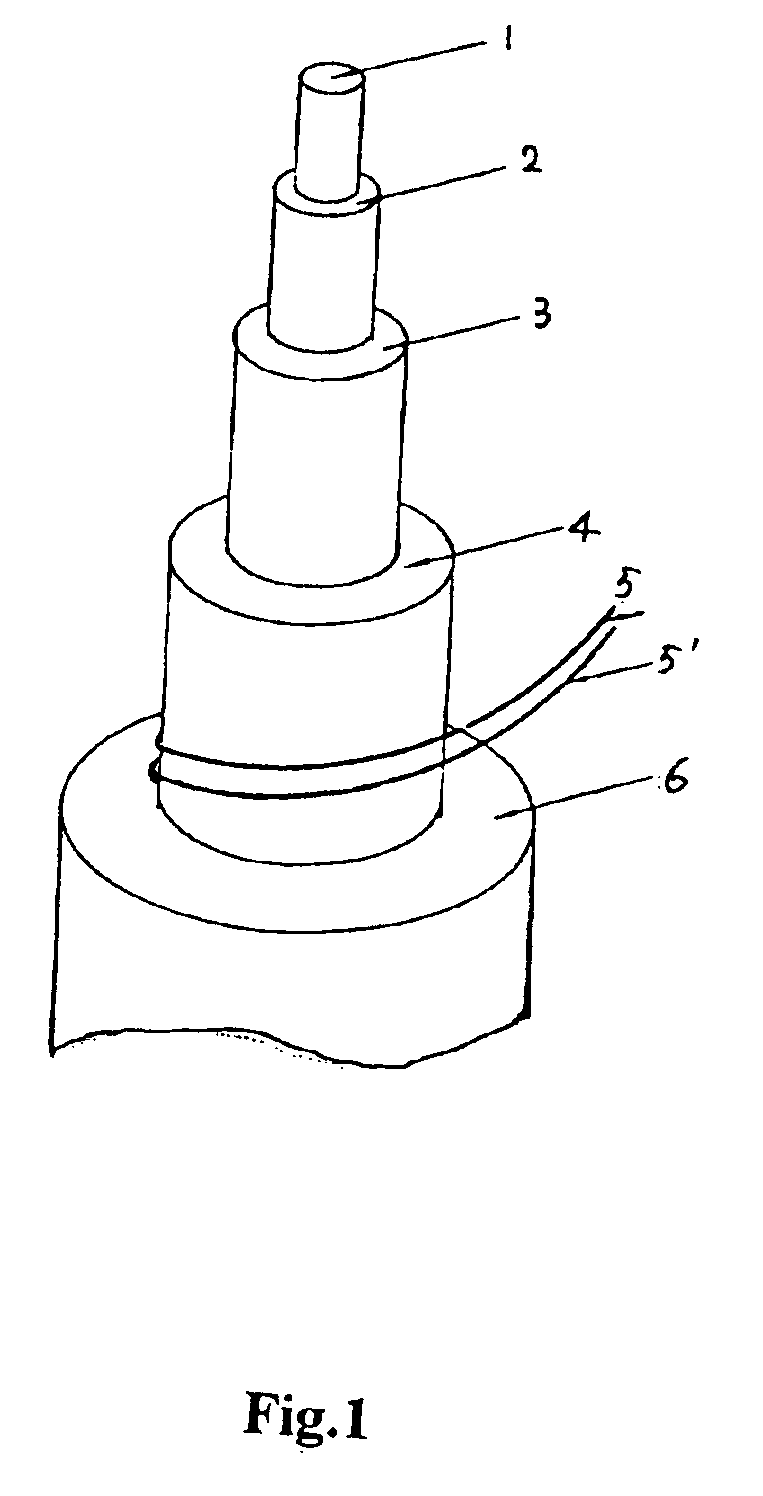

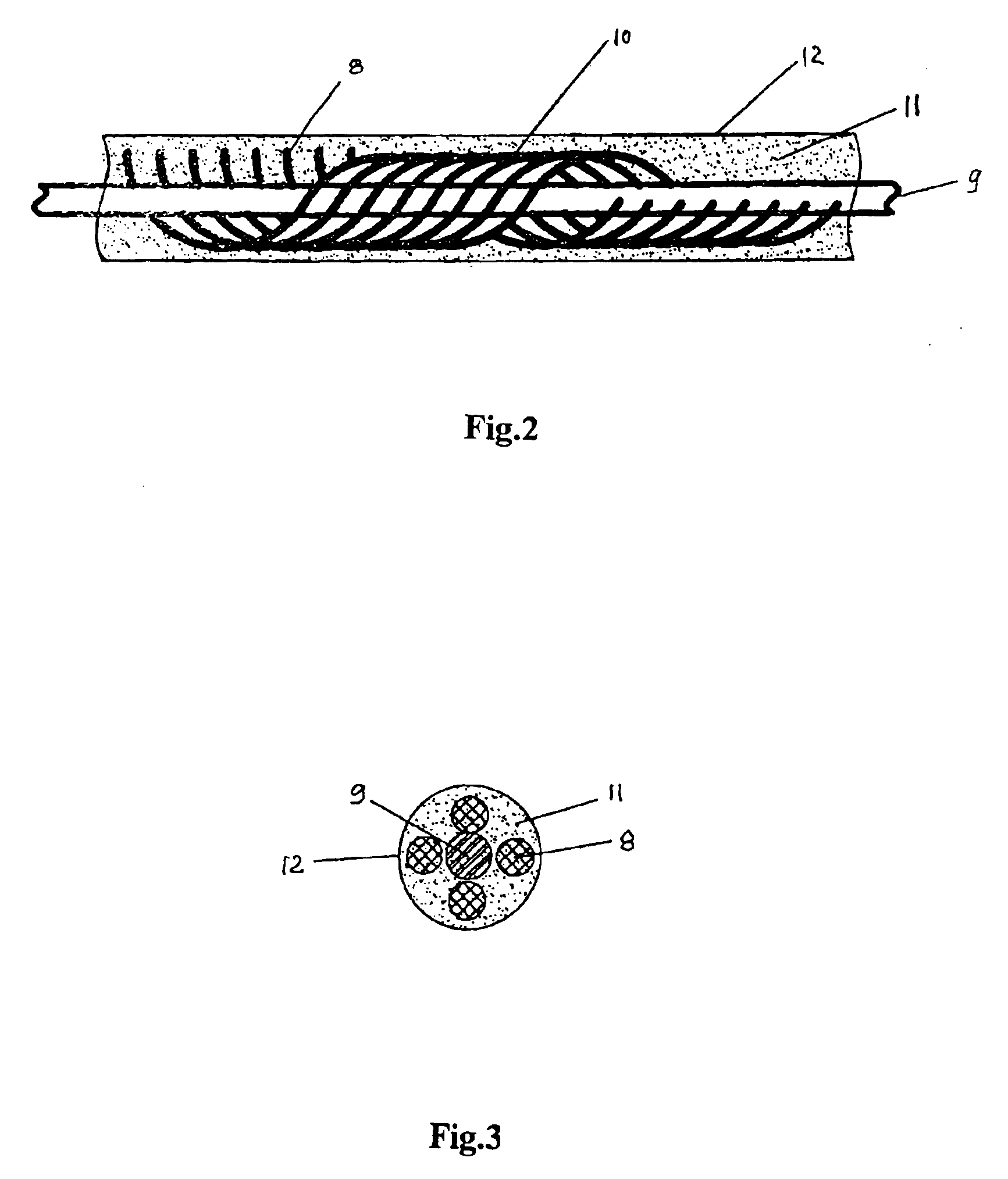

[0054]As shown in FIGS. 2 and 3, a color-changing and multi-colored electroluminescent cable 12, comprising:[0055]a core wire made of Aluminum as a central axis 9;[0056]a group of electroluminescent filaments 10 consisting of a plurality of electroluminescent filaments 8 of different colors which are insulated from each other and helically wound on the outer side of the axis 9;[0057]a transparent polymer casing tube 11 disposed on the outer side of the group of electroluminescent filaments 10 to form a flexible light emitting cable 12.

[0058]Wherein the diameter of the central axis 9 is 0.5-10 mm.

[0059]Wherein each electroluminescent filament 8 of the group of electroluminescent filaments 10 is connect with the programmable electronic elements (not shown in the figures) respectively, and the programmable electronic elements control each electroluminescent filament 8 respectively to emit light according to a predetermined program.

embodiment 2

[0064]As shown in FIG. 4, a color-changing and multi-colored electroluminescent cable without axis, comprising:[0065]a group of electroluminescent filaments 10 consisting of a plurality of electroluminescent filaments 8 of different colors which are insulated from each other and helically wrung together in the same direction;[0066]a transparent polymer casing tube 11 disposed on an outer side of the group of electroluminescent filaments 10 to form a flexible light emitting cable 13;[0067]wherein each filament 8 of the group of electroluminescent filaments 10 is connect with the programmable electronic elements respectively, and said programmable electronic elements control each electroluminescent filament 8 respectively to emit light according to a predetermined program.

[0068]After AC power supply having a voltage ranging from 50 to 300 V and frequency ranging from 200 to 10000 HZ is input, under the control of programmable electronic elements, an electric field is generated between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com