Assembly for correcting laser illumination emitted from a laser light source and method for producing said assembly

a laser light source and laser light source technology, applied in lasers, laser optical devices, recording devices, etc., can solve the problems of difficult production of assembly, difficult production, and inability to meet the requirements of the application, and achieve the effect of easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

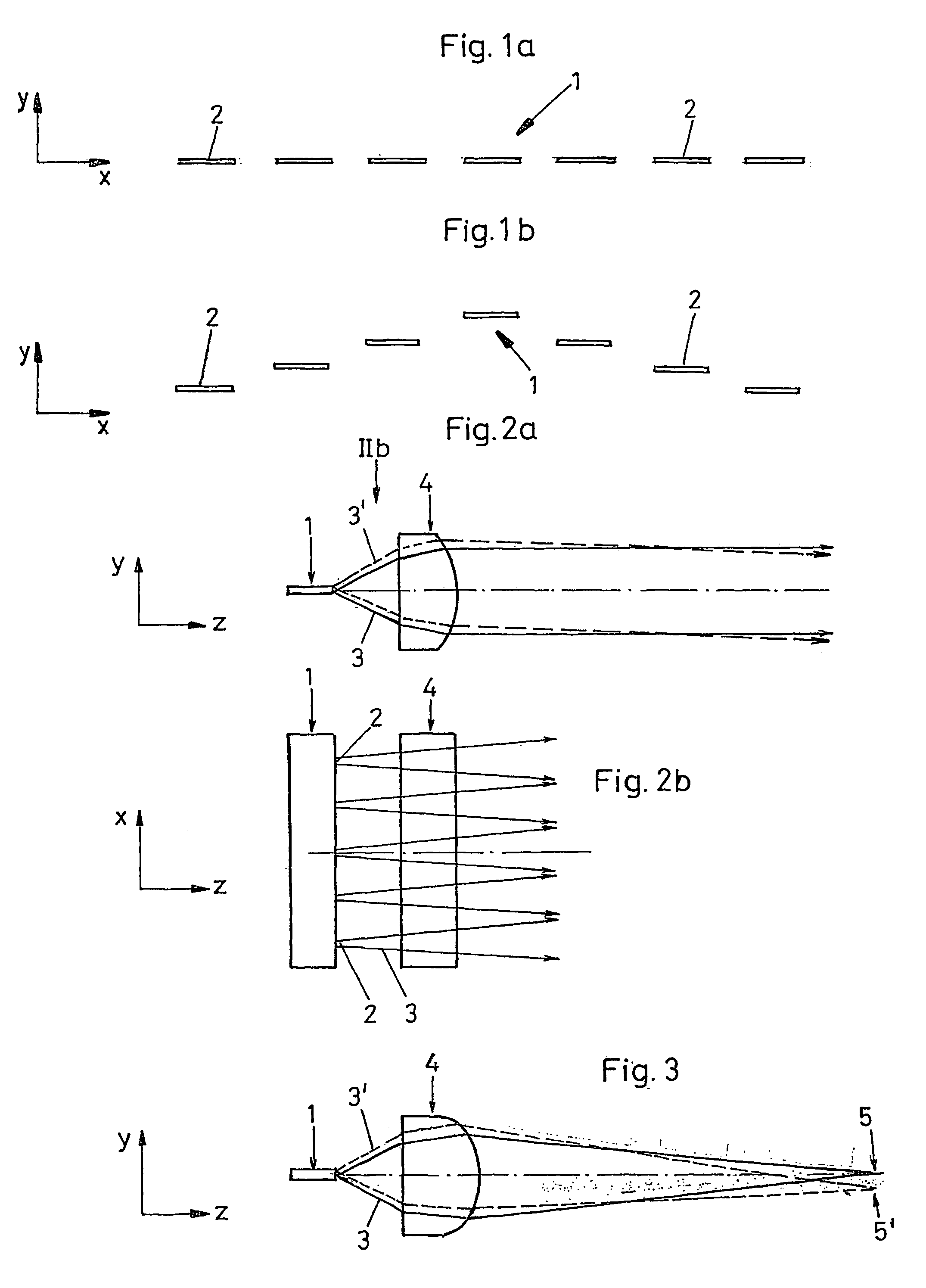

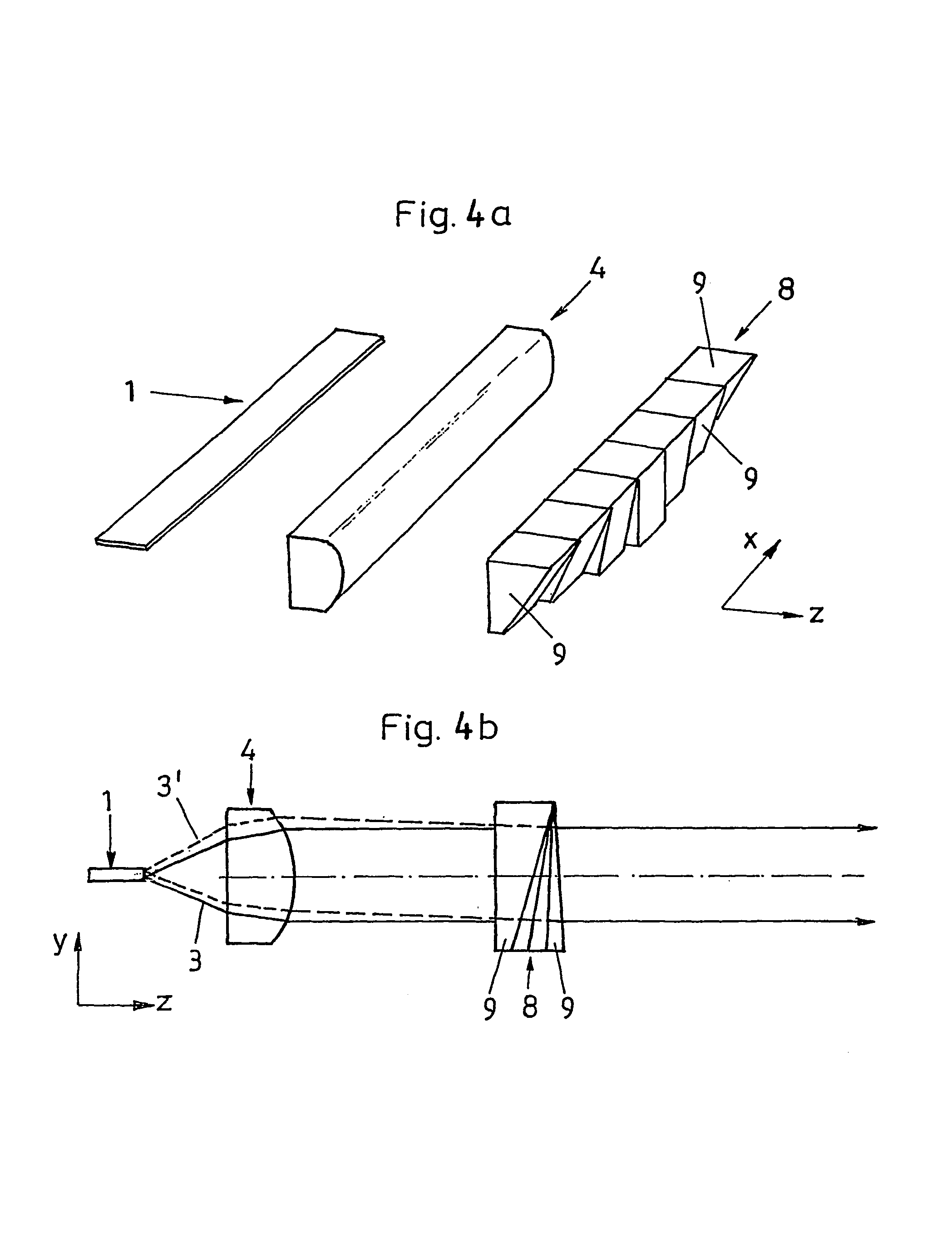

[0027]FIGS. 1 to 4 and FIGS. 6 and 7 show coordinate systems for illustrating the orientation.

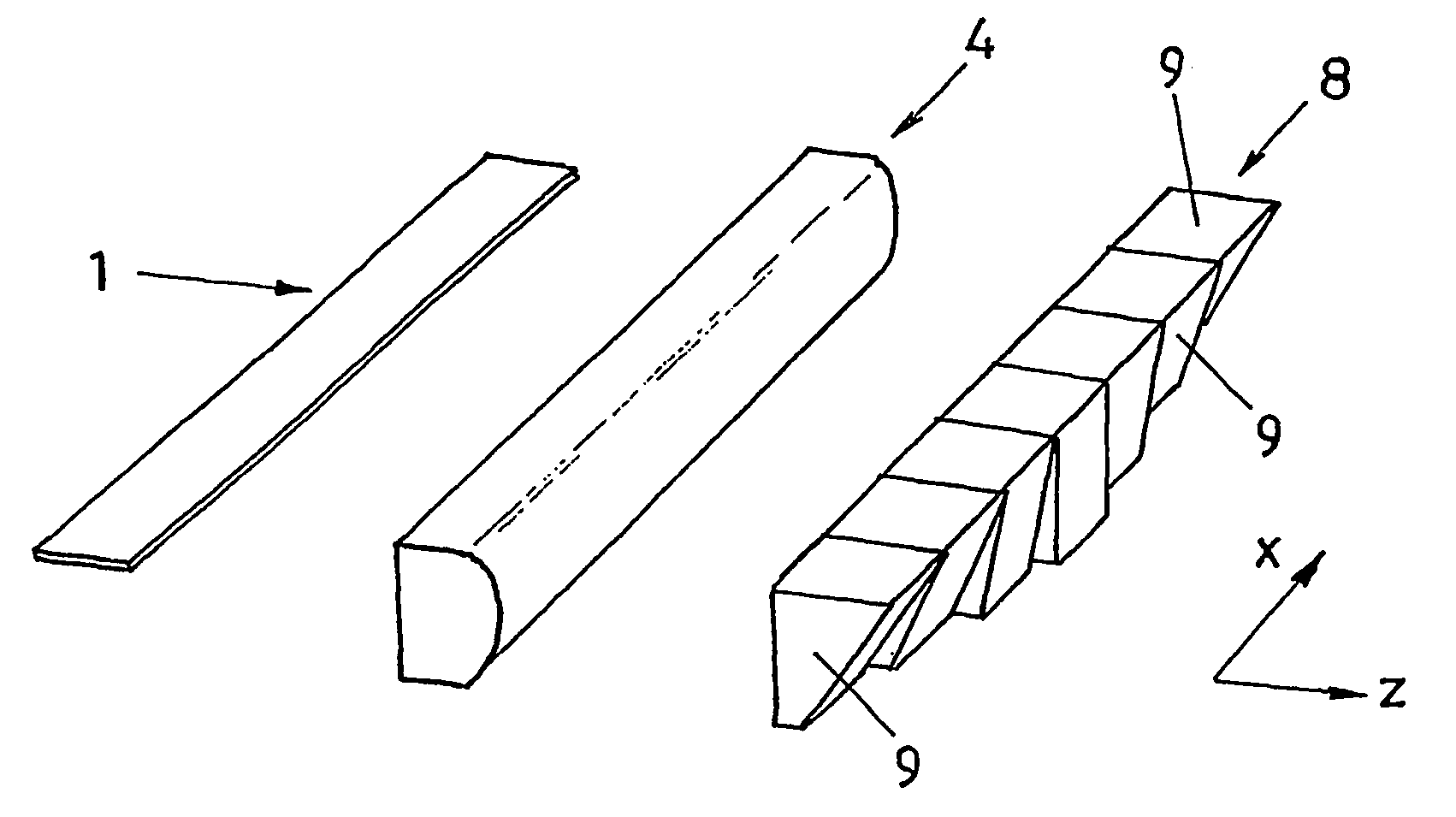

[0028]FIG. 1a shows a schematic view of a laser light source 1 with emission sources 2 located in a row. These laser light sources 1 are generally made as laser diode bars. The dimensions can be, for example, such that the entire width of the laser diode bar in the direction of the illustrated row is roughly 10 mm, conversely the width in the direction of the row of the individual emission sources 2 is roughly 200 microns. The proportions are not true to nature here, but are shown only schematically in order to illustrate the problems associated with the “smile” distortion which is detailed below. The spread of the emission sources 2 in one direction perpendicular to the direction of the row is for example 1 micron.

[0029]FIG. 1b shows emission sources 2 which are not ideally arranged and thus which roughly reproduce the light emitted from the laser diode bar. It is clear that the individual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com