Method for forming a multilayer structure

a multi-layer structure and etching method technology, applied in the field of forming multi-layer structures, can solve the problems of high selectivity, high etch rate and high selectivity of silicon-germanium etching methods, and unsuitable multi-layer structures for several devices, etc., to achieve the effect of removing quickly and selectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

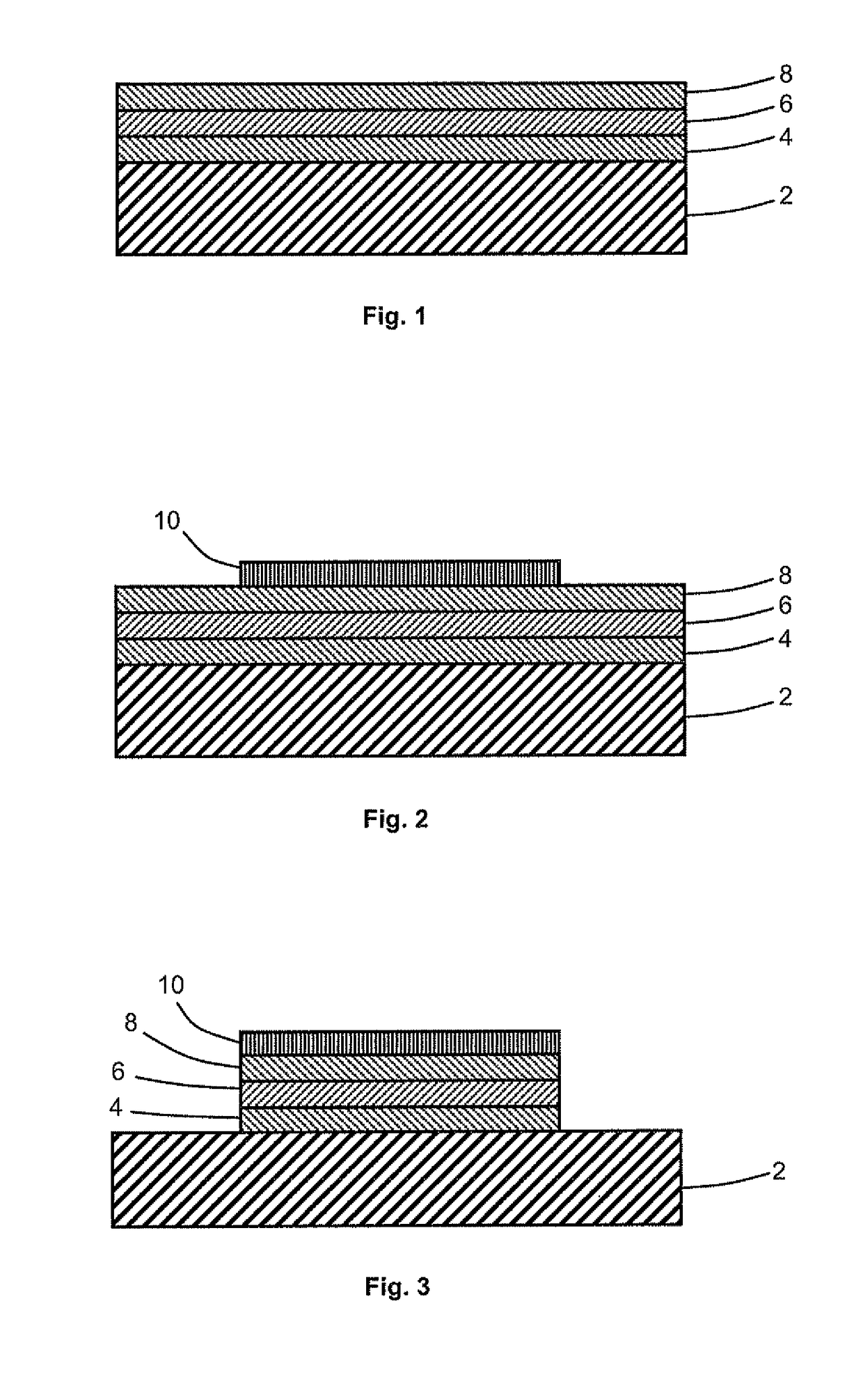

[0020]It is envisaged to form a multilayer structure comprising at least one bulk silicon layer and one porous silicon layer. Unlike silicon-germanium, porous silicon can be etched quickly and with great selectivity with respect to bulk silicon.

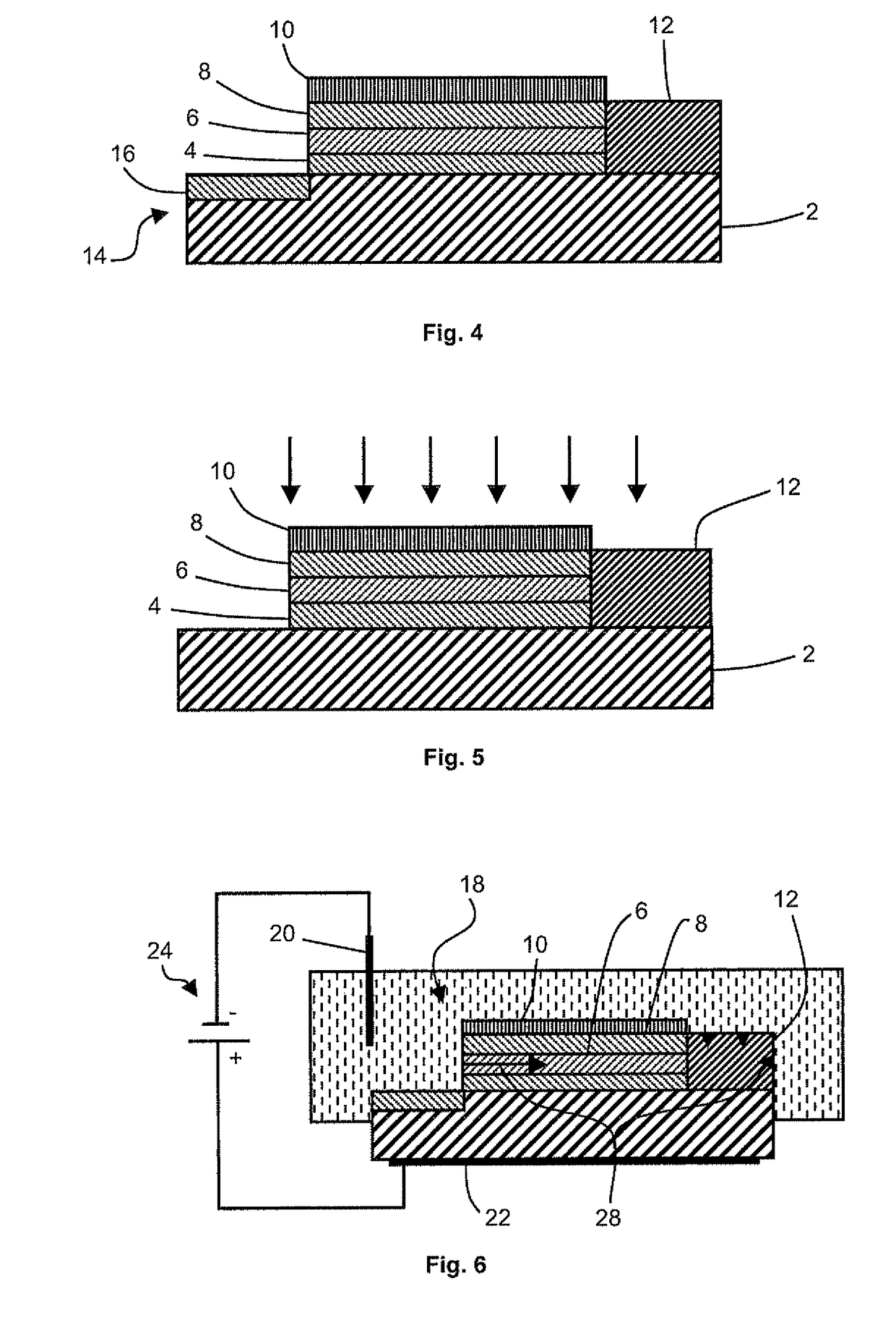

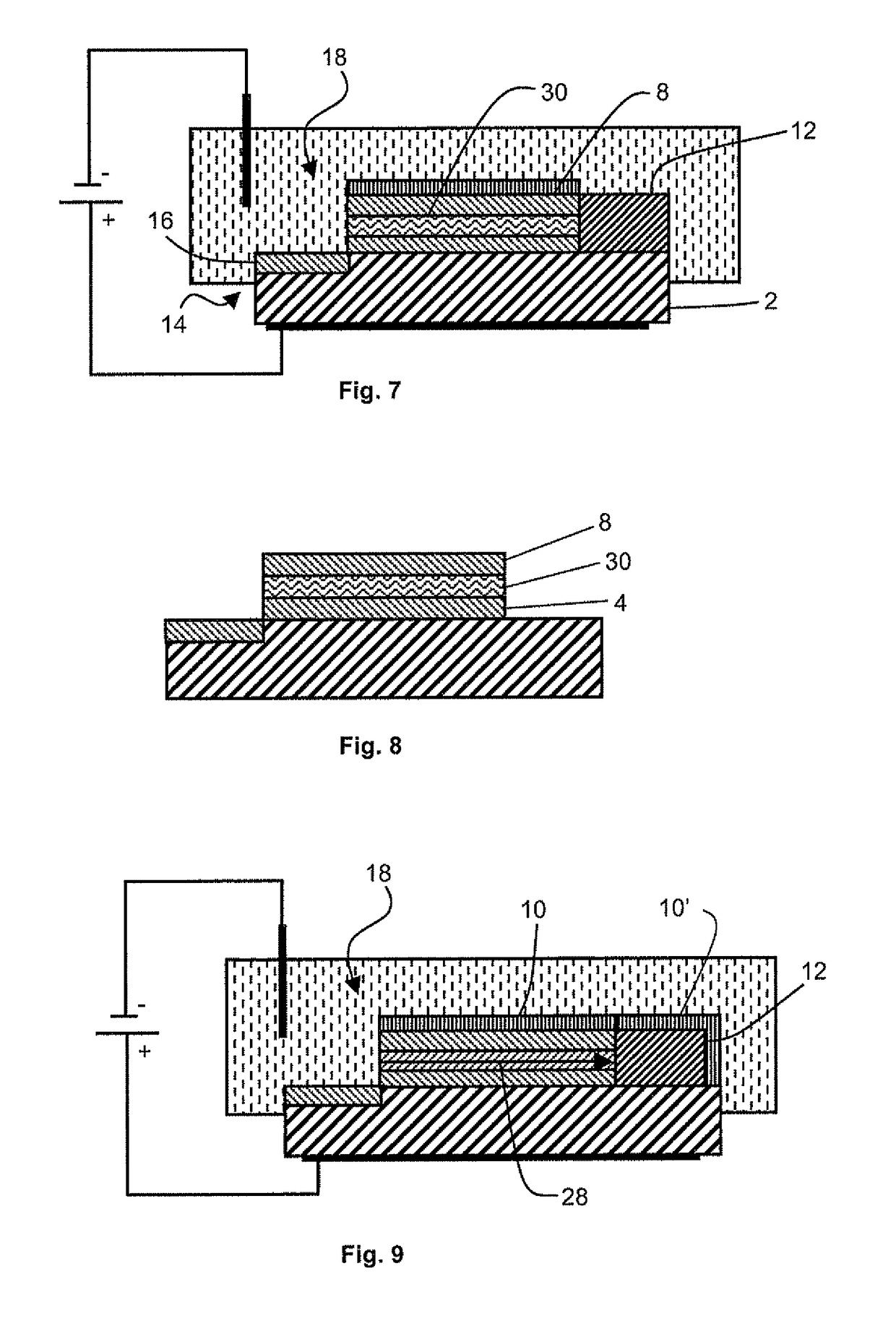

[0021]Porous silicon is generally obtained by anodic dissolution, also called anodization, of a sample of bulk silicon in a hydrofluoric acid (HF) based-electrolyte. The silicon sample is placed in an electrochemical bath having a hydrofluoric acid concentration comprised between about 1% and 50%. An electric field is applied by placing a first electrode (cathode) in the electrolyte and a second electrode (anode) in electric contact with the sample. This contact can be direct by applying the electrode on the sample, or indirect, for example via an electrolyte. In certain cases, the sample is exposed to light radiation to enable the dissolution reaction.

[0022]Anodization of the silicon results from an equilibrium between mass transport in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com