Degradation promoter of biodegradable resin molded body, and use thereof

a biodegradable resin and promoter technology, applied in detergent compounding agents, halogen oxide/oxyacids, other chemical processes, etc., can solve the problems of incineration disposal of resin molded bodies, poisonous gas generation, adverse environmental effects, etc., and achieve rapid spontaneous degradation and accelerate biodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

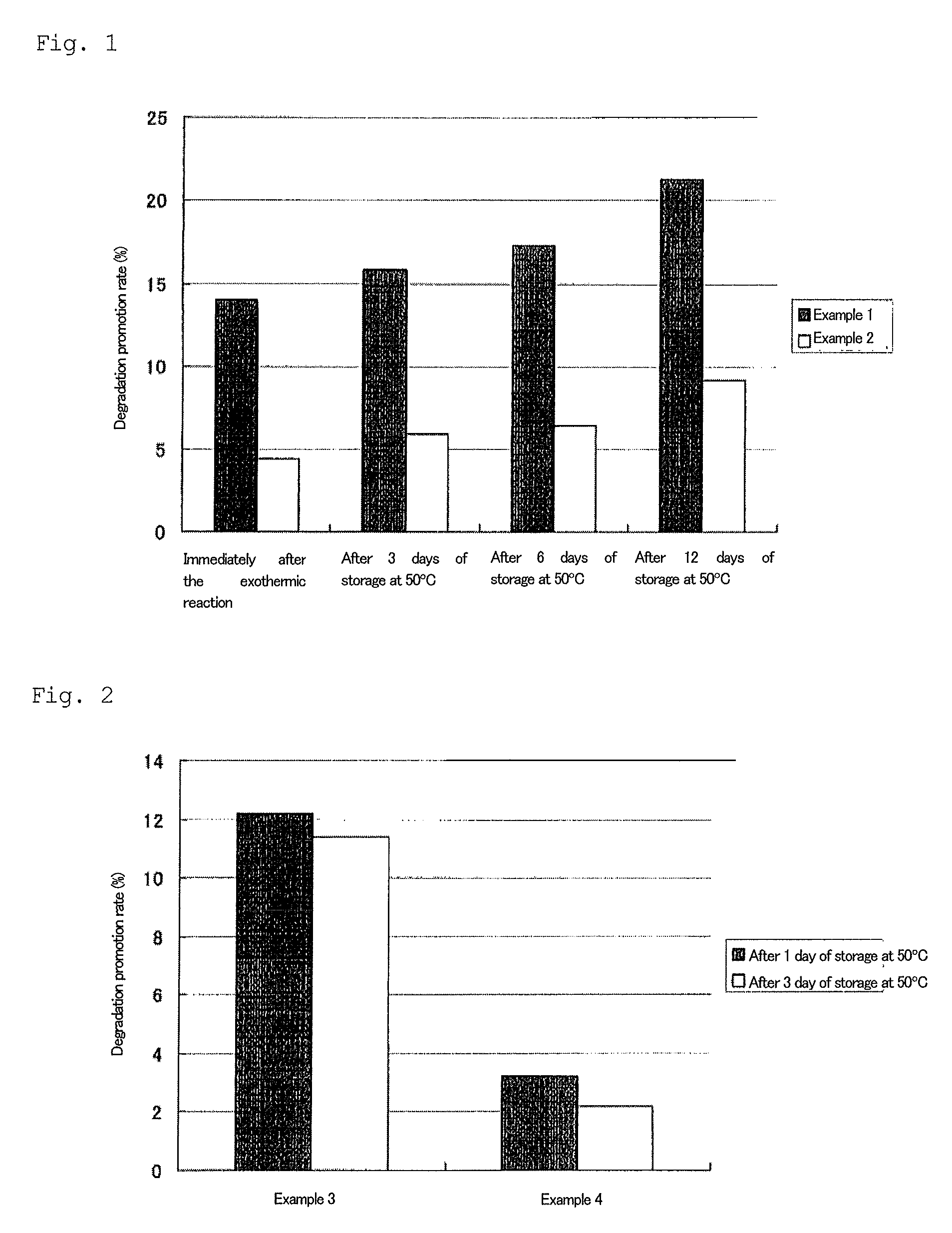

example 1

Preparation of Biodegradable Product (Disposable Body Warmer)

1. Preparation of Functional Composition (Exothermic Composition)

[0071]1 mass % of potassium chloride, 55 mass % of iron powder having an average particle diameter of 50 μm, 13 mass % of activated carbon having an average particle diameter of 200 μm, 26 mass % of water, 3 mass % of vermiculite having a particle diameter of 100 μm, and 2 mass % of a crosslinked partial sodium salt of an acrylic acid polymer having a particle diameter of 380 μm were mixed to prepare an exothermic composition.

2. Preparation of Resin Molded Body (Inner Bag Material of Disposable Body Warmer)

[0072]A resin sheet consisting of 98 mass % of polyethylene and 2 mass % of an oxidative degradation agent-containing material was brought into contact with a rotating roll comprising a row of disc-shaped members, each disc-shaped member having blades on the circumference, to prepare a breathable resin film (thickness: 40 μm) having fine pores with a size t...

example 2

Preparation of Biodegradable Product (Disposable Body Warmer)

[0075]A disposable body warmer was produced under the same conditions as in Example 1, except that 1 mass % of sodium chloride was used in place of 1 mass % of potassium chloride.

examples 3 and 4

Biodegradable Products (Non-Exothermic Composition-Containing Products)

[0079]2.2 mass % of potassium chloride, 28.9 mass % of activated carbon having an average particle diameter of 200 μm, 57.8 mass % of water, 6.7 mass % of vermiculite having a particle diameter of 100 μm, and 4.4 mass % of a crosslinked partial sodium salt of an acrylic acid polymer having a particle diameter of 380 μm were mixed to prepare a non-exothermic composition (functional composition). Twenty grams of the obtained non-exothermic composition was enclosed in the same inner bag (biodegradable resin molded body) as that used in Example 1 to prepare a non-exothermic composition-containing product (Example 3).

[0080]Another non-exothermic composition-containing product (Example 4) was prepared under the same conditions as in Example 3, except that 2.2 mass % of sodium chloride was used in place of 2.2 mass % of potassium chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com