Adjustable light for underwater photography

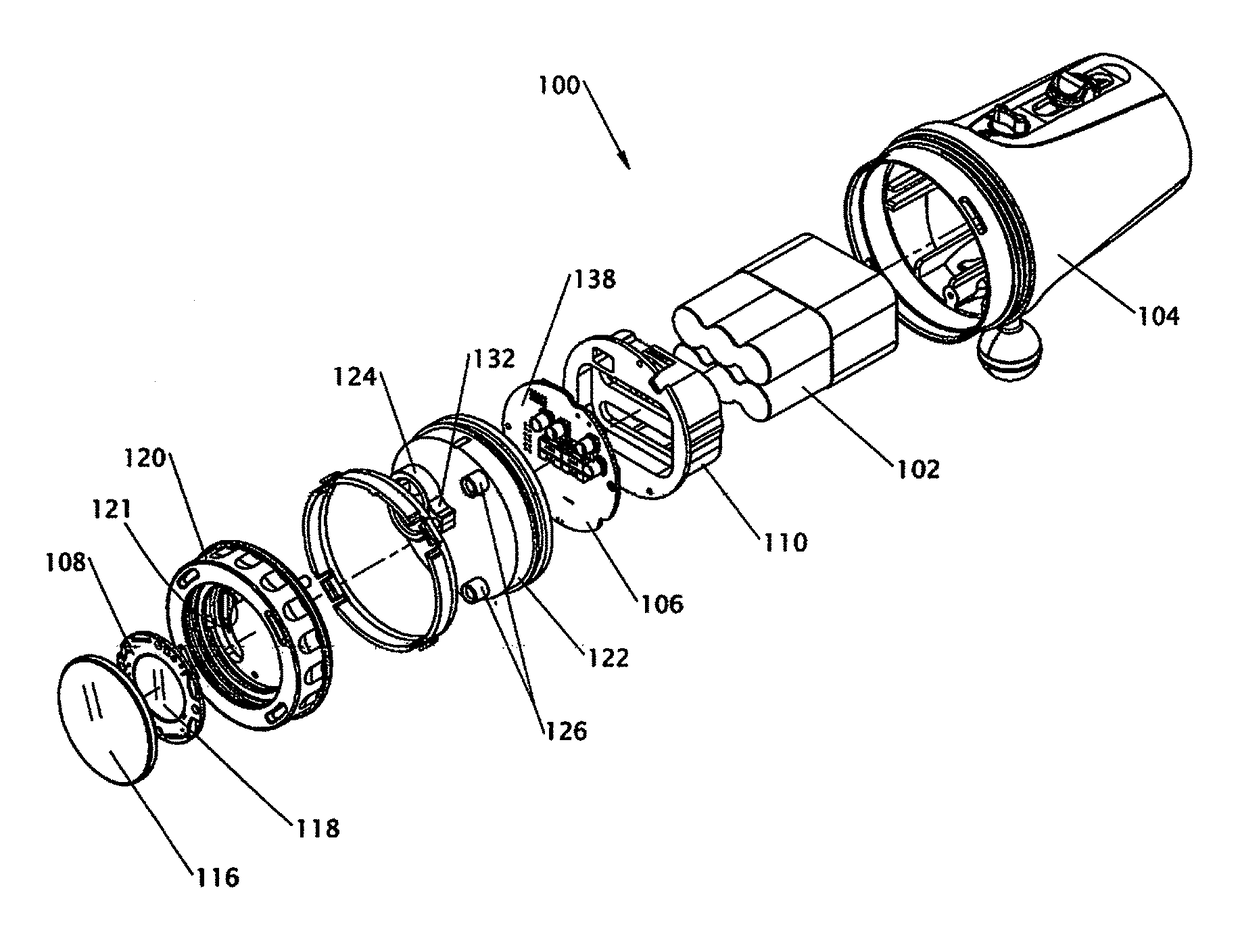

a technology for underwater photography and adjustment light, which is applied in underwater equipment, camera filters, instruments, etc., can solve problems such as flooding and corrosion, introducing physical damage or dirt and grime to seals, and generating considerable heat, so as to reduce overall weight, reduce heat path, and reduce the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

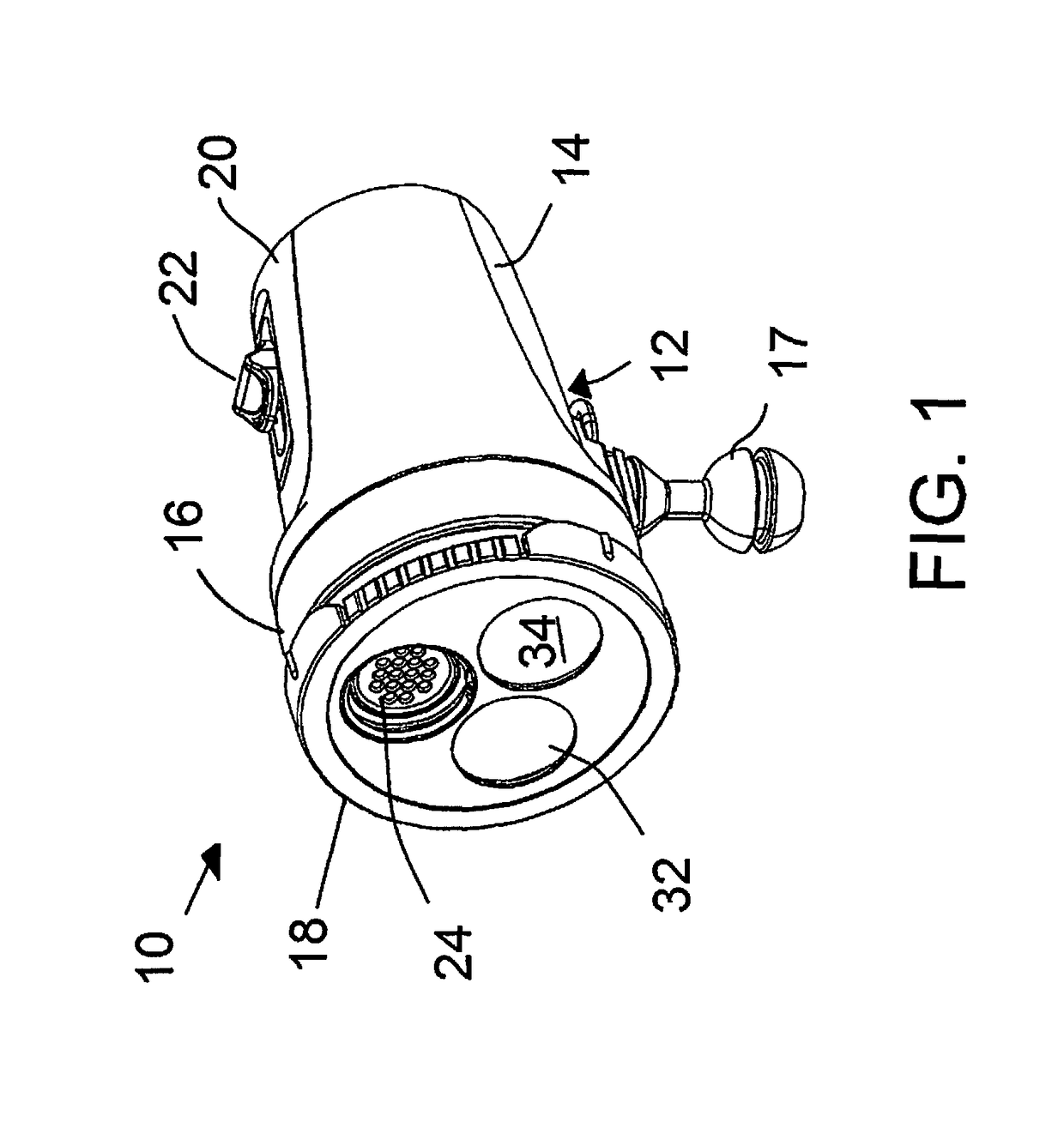

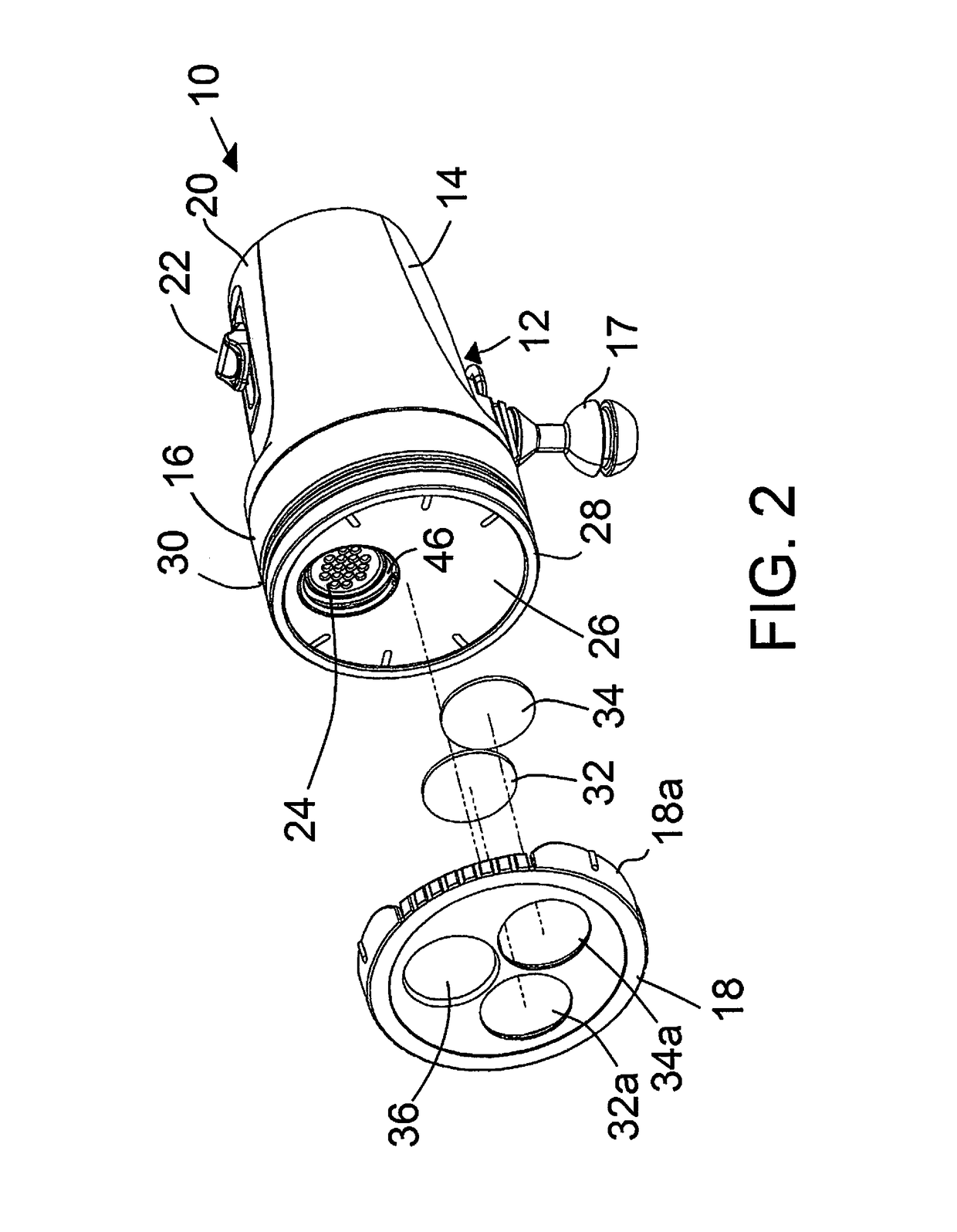

[0047]In the drawings, FIG. 1 shows a dive light 10 having a housing 12 formed of a casing 14, a front section or face assembly 16 attached to the casing, which can be by sealed threaded connection, a mounting interface device 17 and a rotatable filter ring 18. The device 17 is shown as a standard interface, to be received in a socket on a camera light arm accessory. On the casing is a switch assembly 20 with slide switch 22, for switching the dive light on and off and selecting a desired power level. At the front of the dive light device a beam is projected by an array 24 of LEDs in a tight cluster as shown. These may be sixteen in number.

[0048]With reference to both FIGS. 1 and 2, the filter ring 18 snaps onto and off a position of covering the front face 26 of the unit. The front of the unit has a bezel ring 28, forming an annular recess 30, which is gripped by overhanging structure (not shown in FIGS. 1 and 2) on the rim 18a of the filter ring to hold the filter ring in place on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com