Method of introducing leak detection dye into an air conditioning or refrigeration system including solid or semi-solid fluorescent dyes

a leak detection and air conditioning system technology, applied in the field of leak detection, can solve the problems of inability to distinguish between fluorescence from a leak site and that resulting from inadvertent external contact, the nature of the assembly and charging process creates a risk of spillage or inadvertent contamination of clothing or tools, false leak indications, etc., and achieves the effect of reducing the risk of inadvertent conta

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

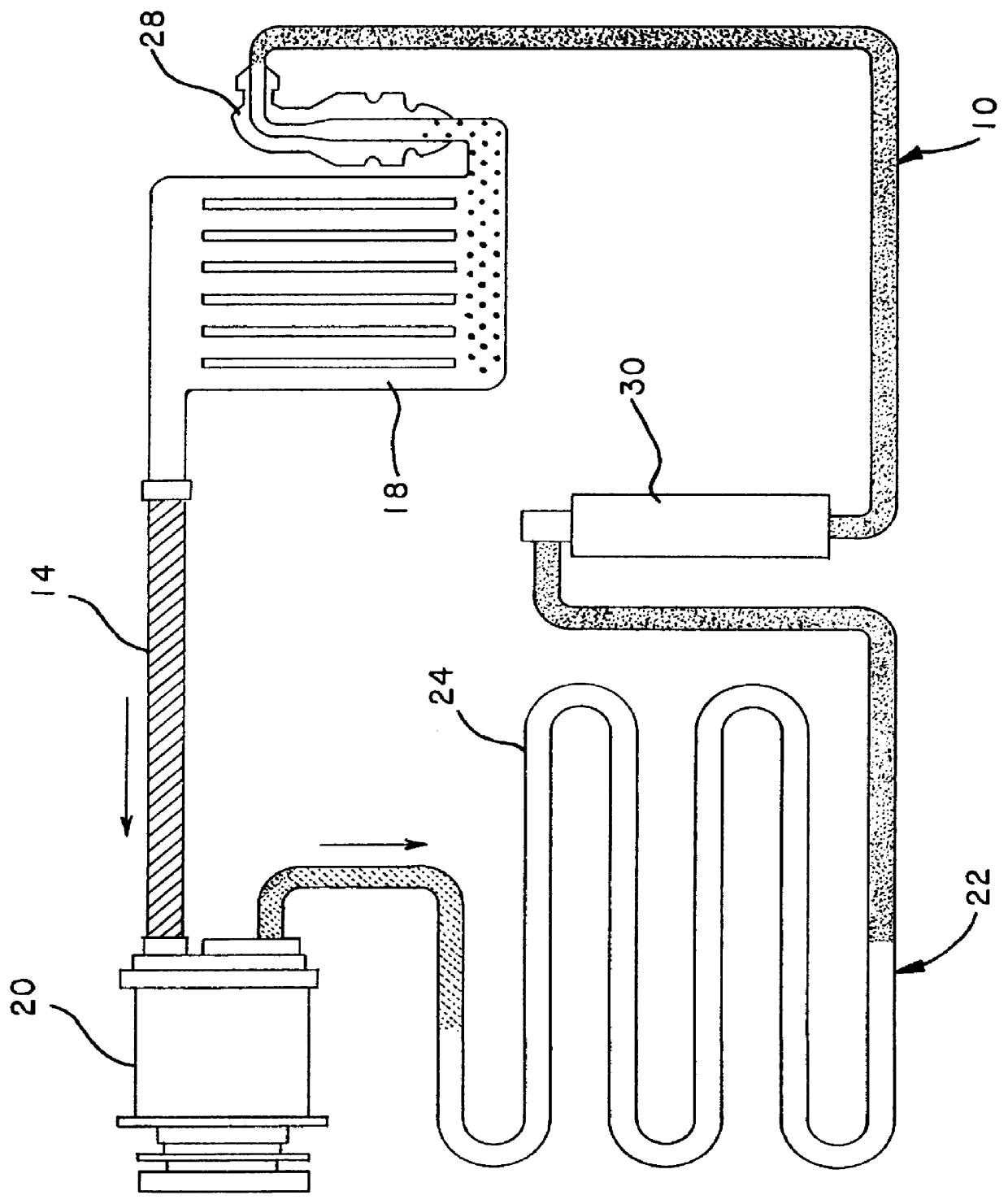

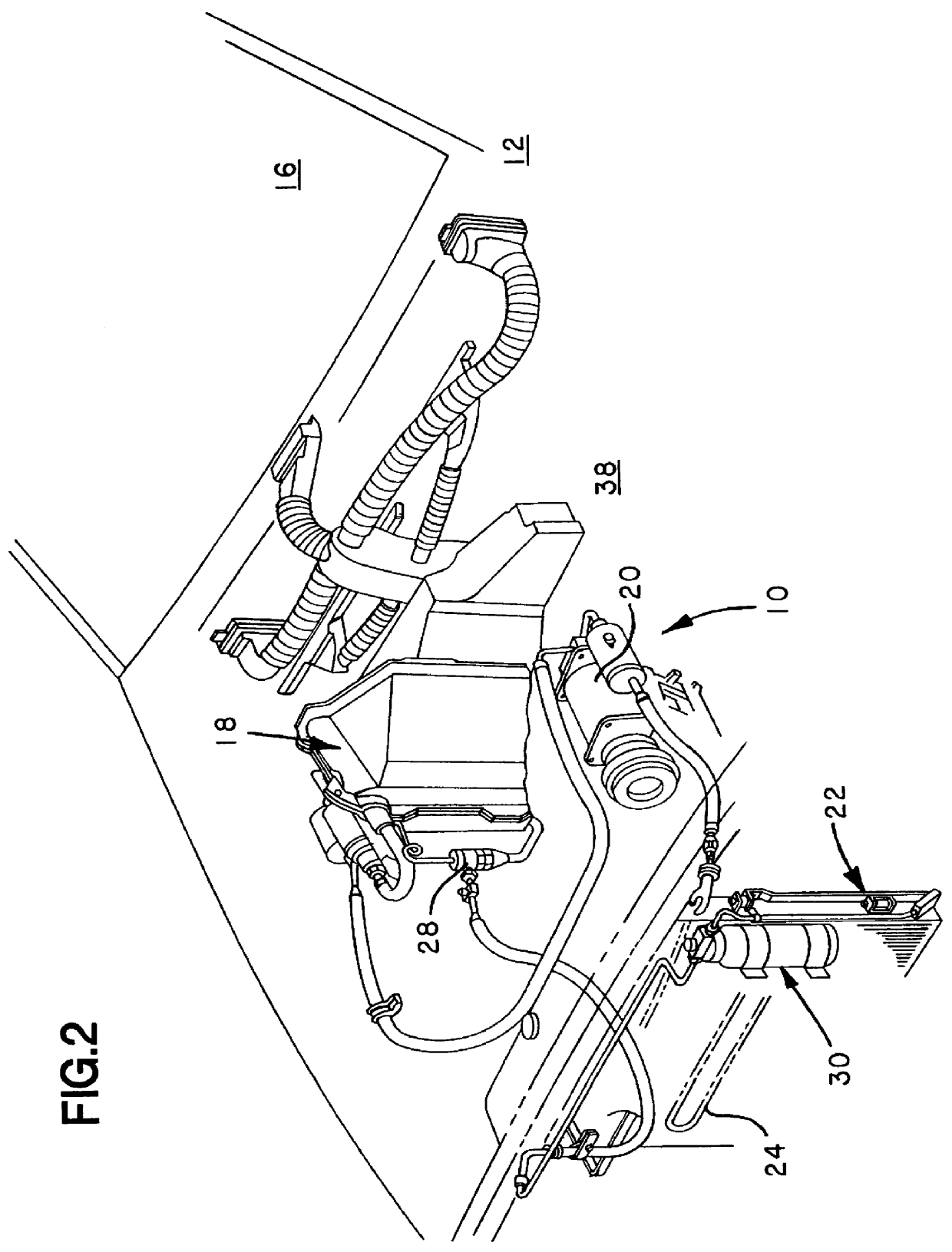

Referring to the drawings, wherein like numerals indicate like elements, FIG. 1 illustrates a basic closed refrigeration circuit 10 of an automobile air conditioner, by which air inside the automobile is cooled and dehumidified. FIG. 2 provides greater detail of the system 10 as it is arranged in an automobile 12.

A refrigerant 14, such as R-12 or more recently R-134a, circulates under pressure in the air conditioning / refrigeration system. In each cycle, the refrigerant is caused to change phase from liquid to gas and back to liquid, absorbing heat from the passenger compartment 16 and releasing heat outside the compartment.

More specifically, the air conditioning system 10 has an evaporator unit 18 where subcooled liquid refrigerant enters and is allowed to expand and absorb heat from warm air of the passenger compartment, causing the refrigerant to vaporize. The warm air of the passenger compartment 16 is connected to the evaporator 18 via ducting, as seen in FIG. 2, such that the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com