Apparatus and method for self adjusting downlink signal communication

a technology of mud pulse and signal communication, which is applied in the direction of survey, instruments, borehole/well accessories, etc., can solve the problems of unavoidable dispersion, mud pulse attenuation and dispersion, and methods that are difficult to use in measurement-while-drilling ("mwd") operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

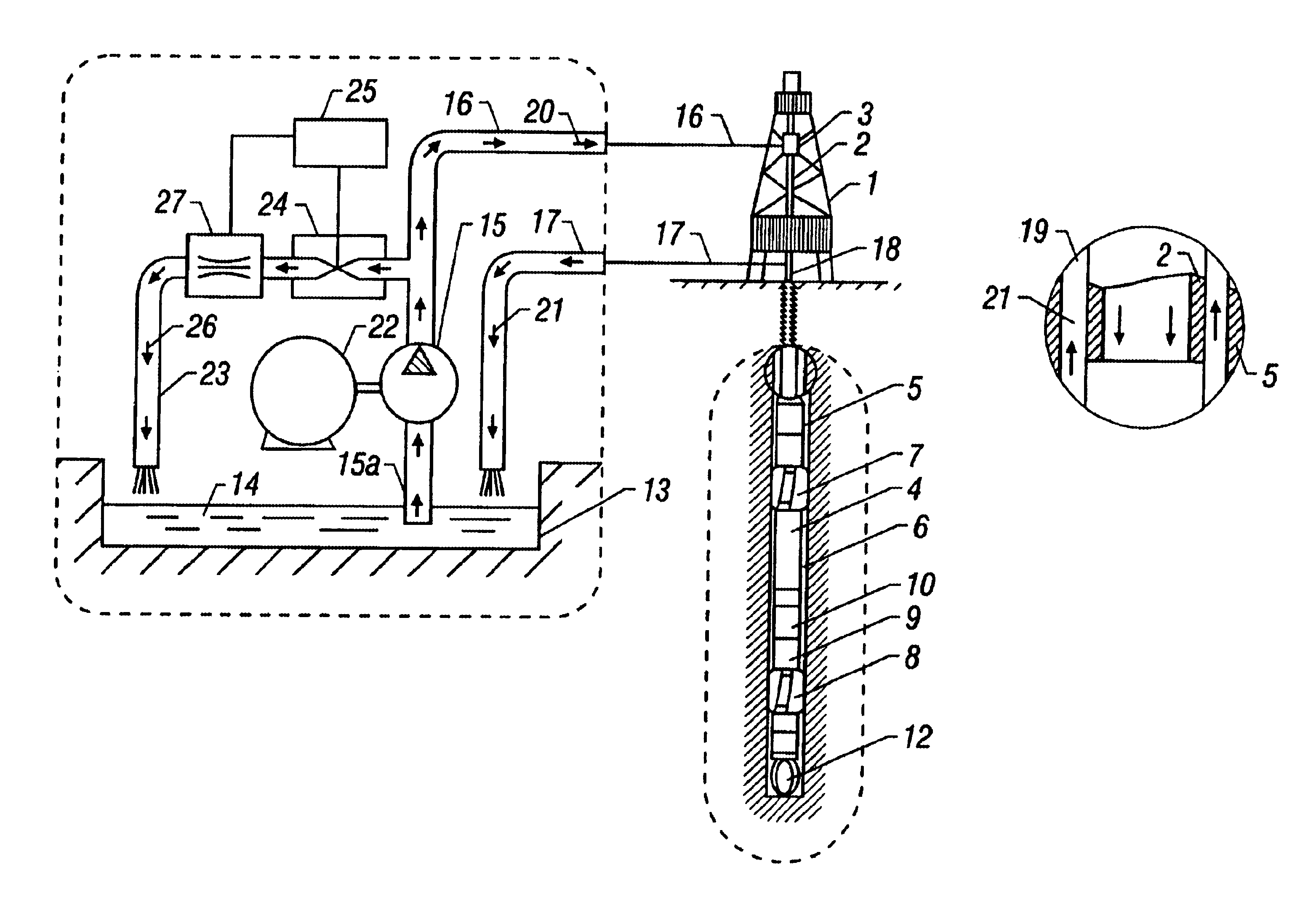

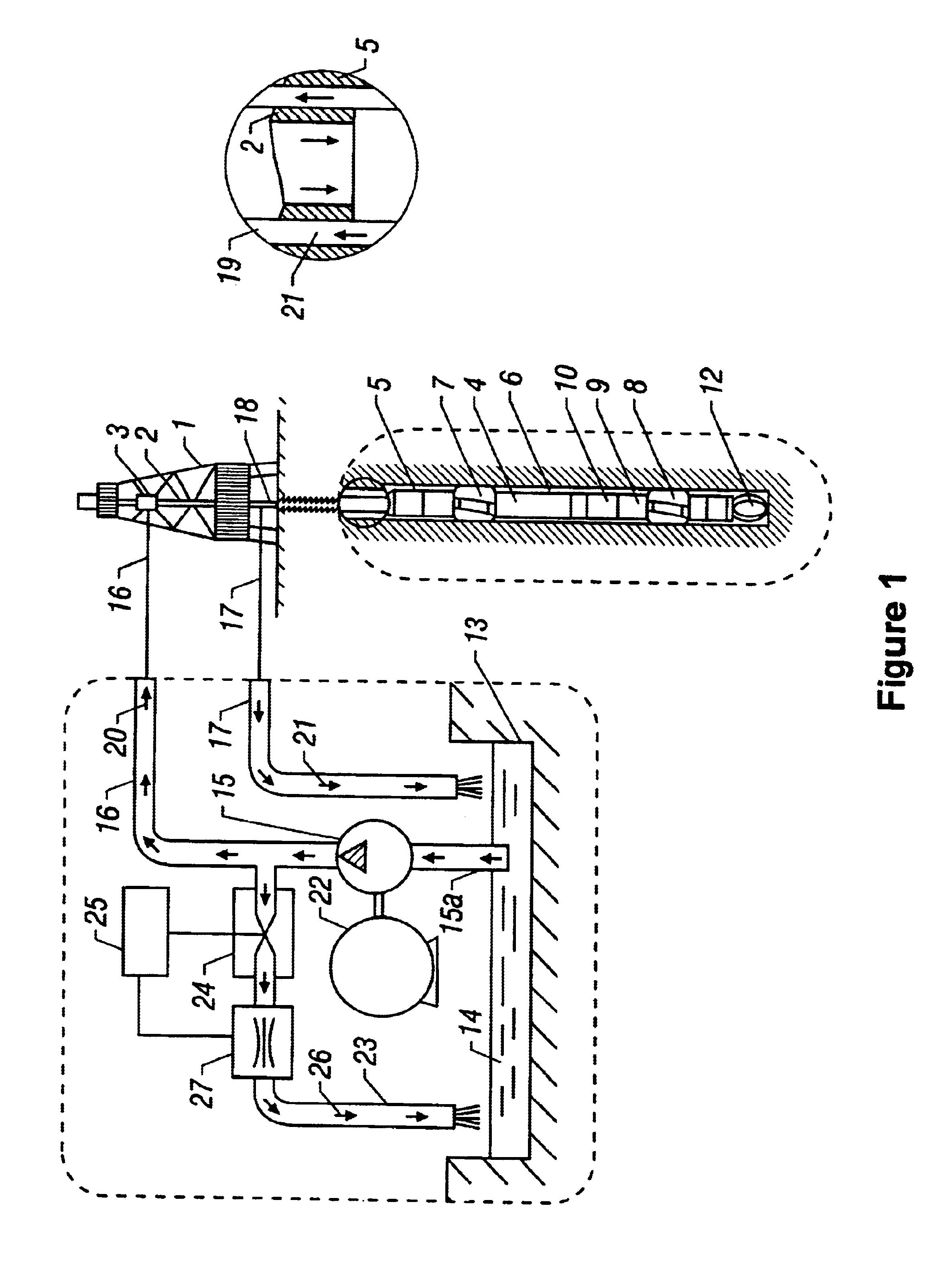

The present invention is best understood by reference to the FIGS. 1-3. FIG. 1 is a schematic illustration of a drilling rig 1 that has a swivel head 3 to which is attached the drill string 2. At the bottom of the drill string 2 is a drilling tool 4. The drilling tool 4 is conveyed in the borehole 5 and includes a housing 6. Attached to the housing are stabilizers 7, 8 for stabilizing for reducing vibrations and a non-rotating sleeve 9 with ribs 10 that can be extended and retracted in a controlled fashion. The ribs are used to control the direction of drilling of the tool. The non-rotating sleeve 9 maintains a substantially fixed orientation in the borehole, independent of the rotation of the drill string 2. The drilling tool 4, together with the drill head 12 can be caused to rotate by using the drill string 2.

FIG. 1 also shows a mud pit 13 in which there is a supply of drilling mud 14. A mud pump 15 has an inlet pipe 15a dipping into the mud and a main pipe 16 connected to the sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com