Powder coating closed circulation pulverizer unit

A closed loop, powder coating technology, applied in grain processing, etc., can solve problems such as environmental pollution, equipment occupation space and high manufacturing difficulty, and achieve the effects of avoiding air pollution, reducing temperature and improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

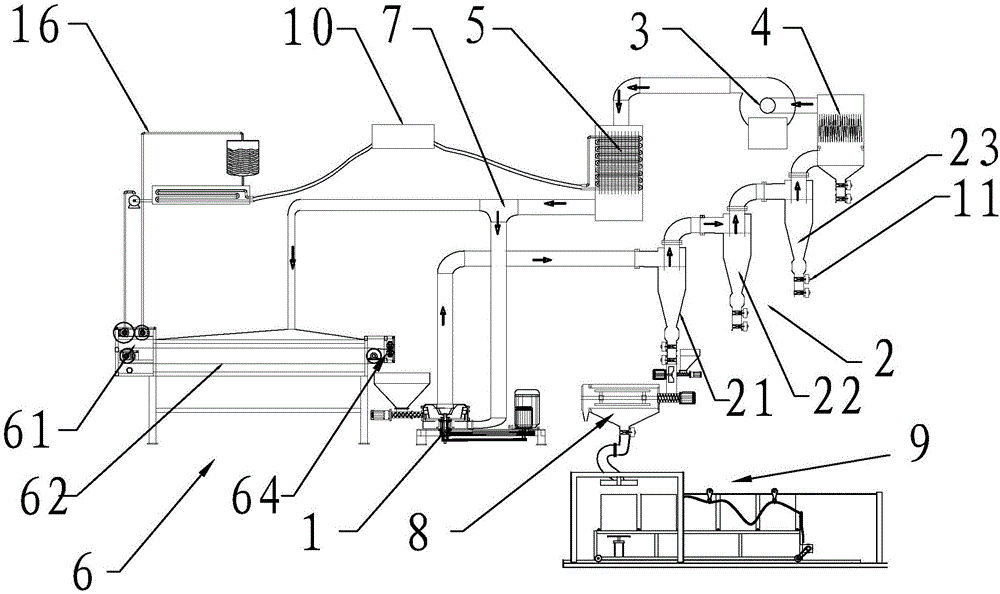

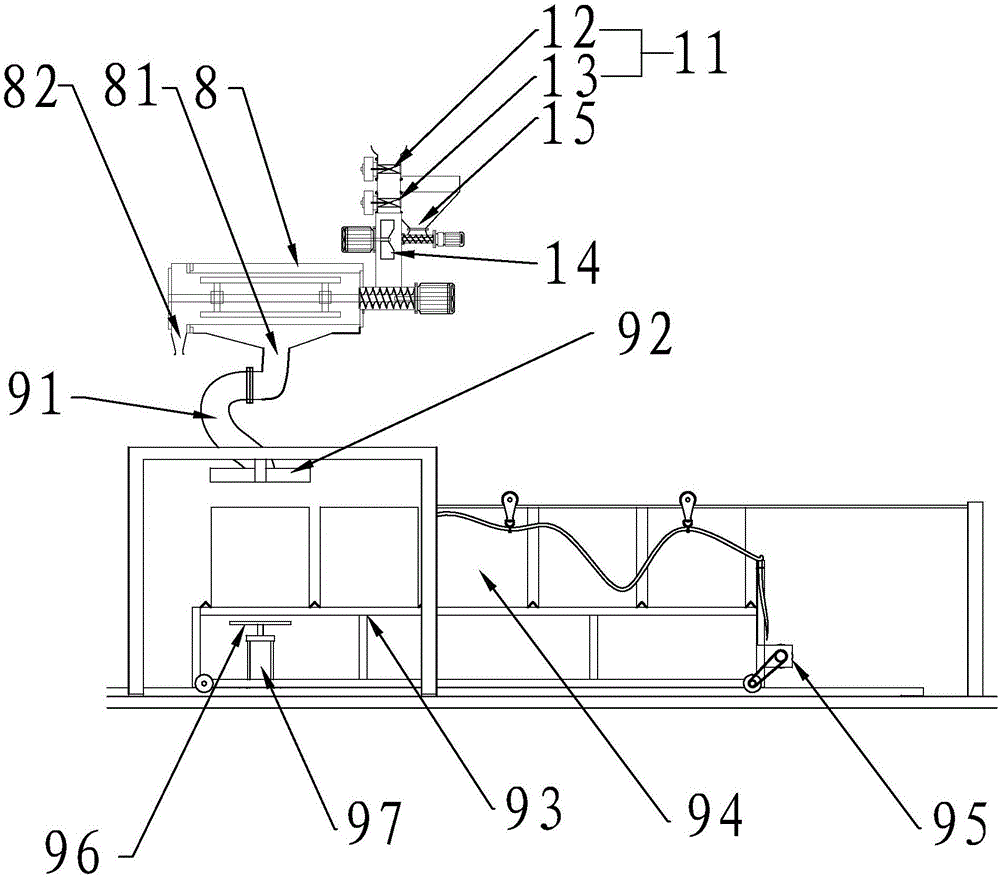

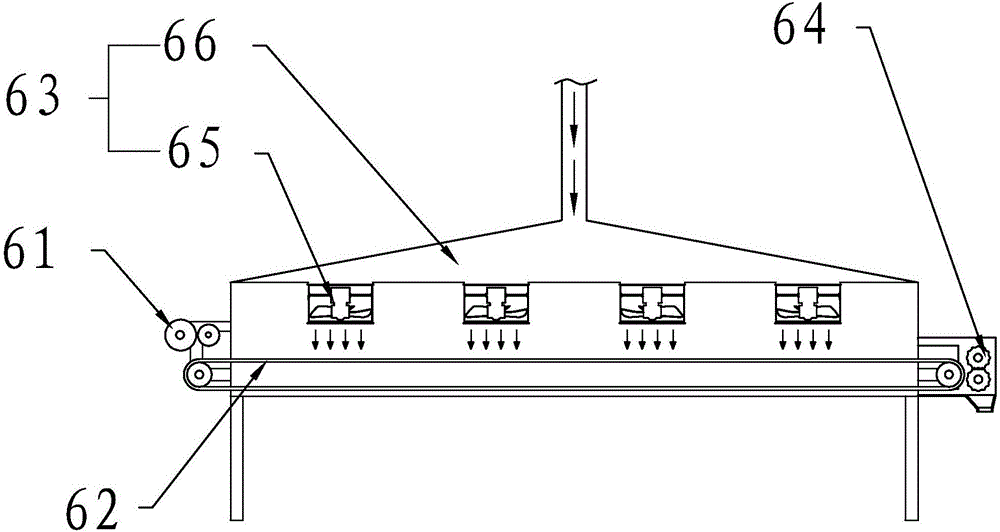

[0040] A powder coating closed-circuit circulation milling unit, refer to figure 1 , starting from the feed, it passes through the mill 1, the cyclone separation unit 2, the bag filter 4, the induced draft fan 3, the evaporator 5 and the bag filter 4, and the evaporator 5 is refrigerated and cooled by the refrigeration compressor unit 10, and the evaporator 5 A tee pipe 7 is arranged between the pulverizer and the mill 1, and the tee pipe 7 diverts a part of the cooled gas back to the pulverizer 1 to cool the pulverizer 1 and reduce the temperature in the pulverizer, and the tee pipe 7 The other opening of the other opening leads to the tablet cooling crusher 6 in front of the pulverizer 1 and is connected to cool the material on the tablet cooling crusher 6 .

[0041] refer to figure 1 and figure 2 , the cyclone separation unit 2 is divided into three stages, followed by the first-stage cyclone separator 21, the second-stage cyclone separator 22, the third-stage cyclone se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com