Semiconductor switching apparatus and method of controlling a semiconductor switching element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]A semiconductor switching apparatus or a semiconductor switching element is applied for various types of power converters, such as a power converter on traction, an SVG (Static Var Generator) and an industrial power converter.

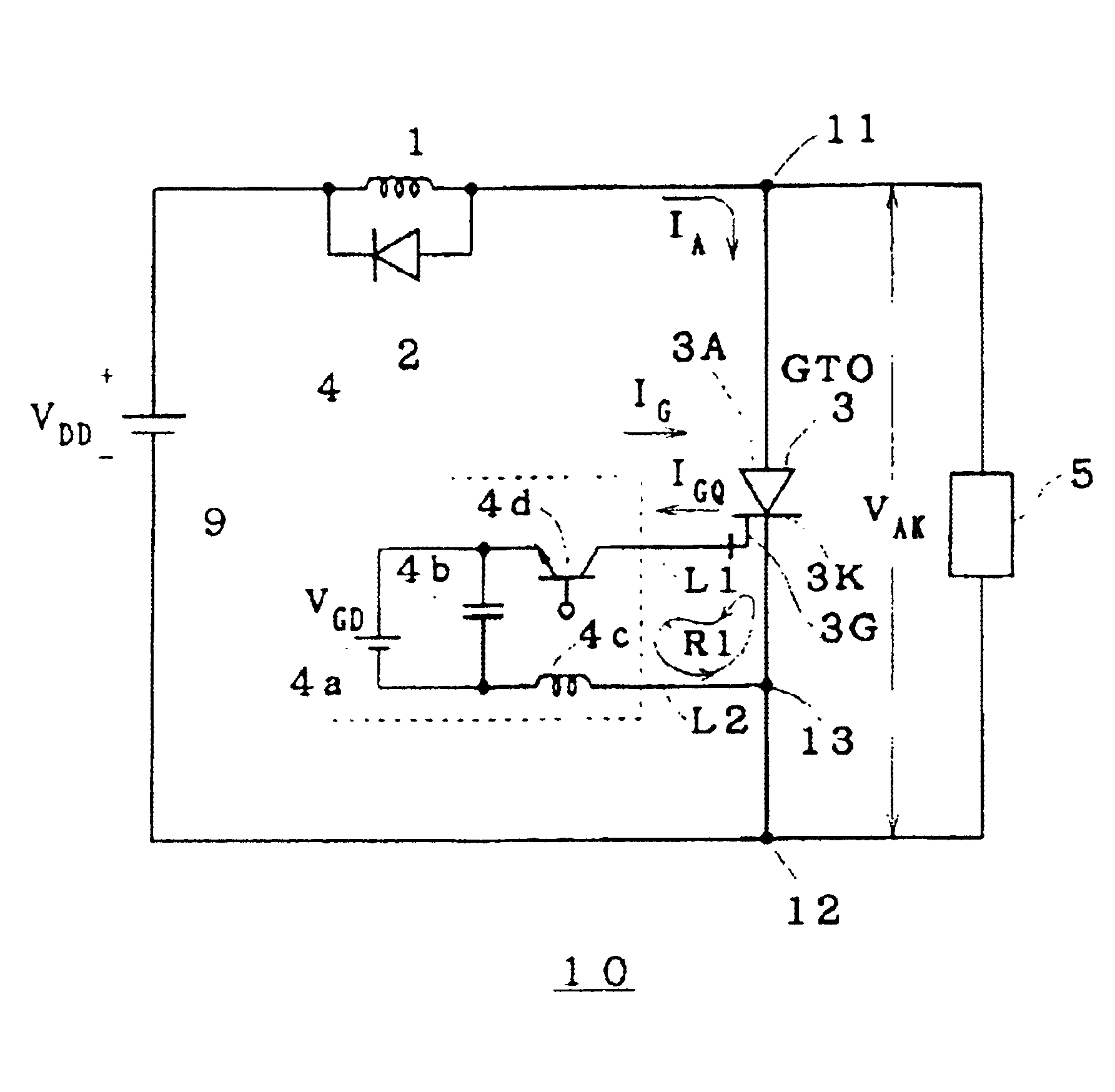

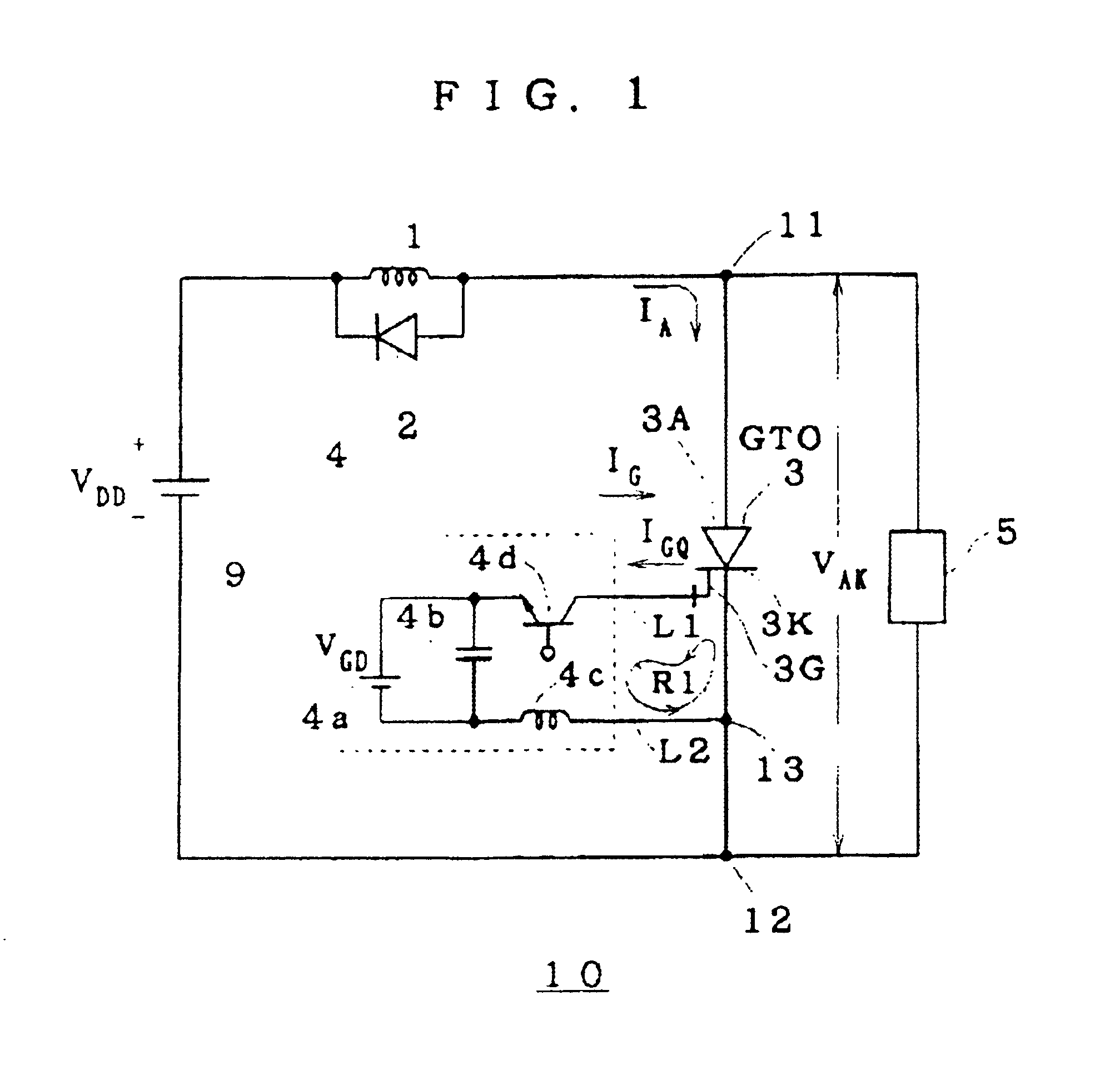

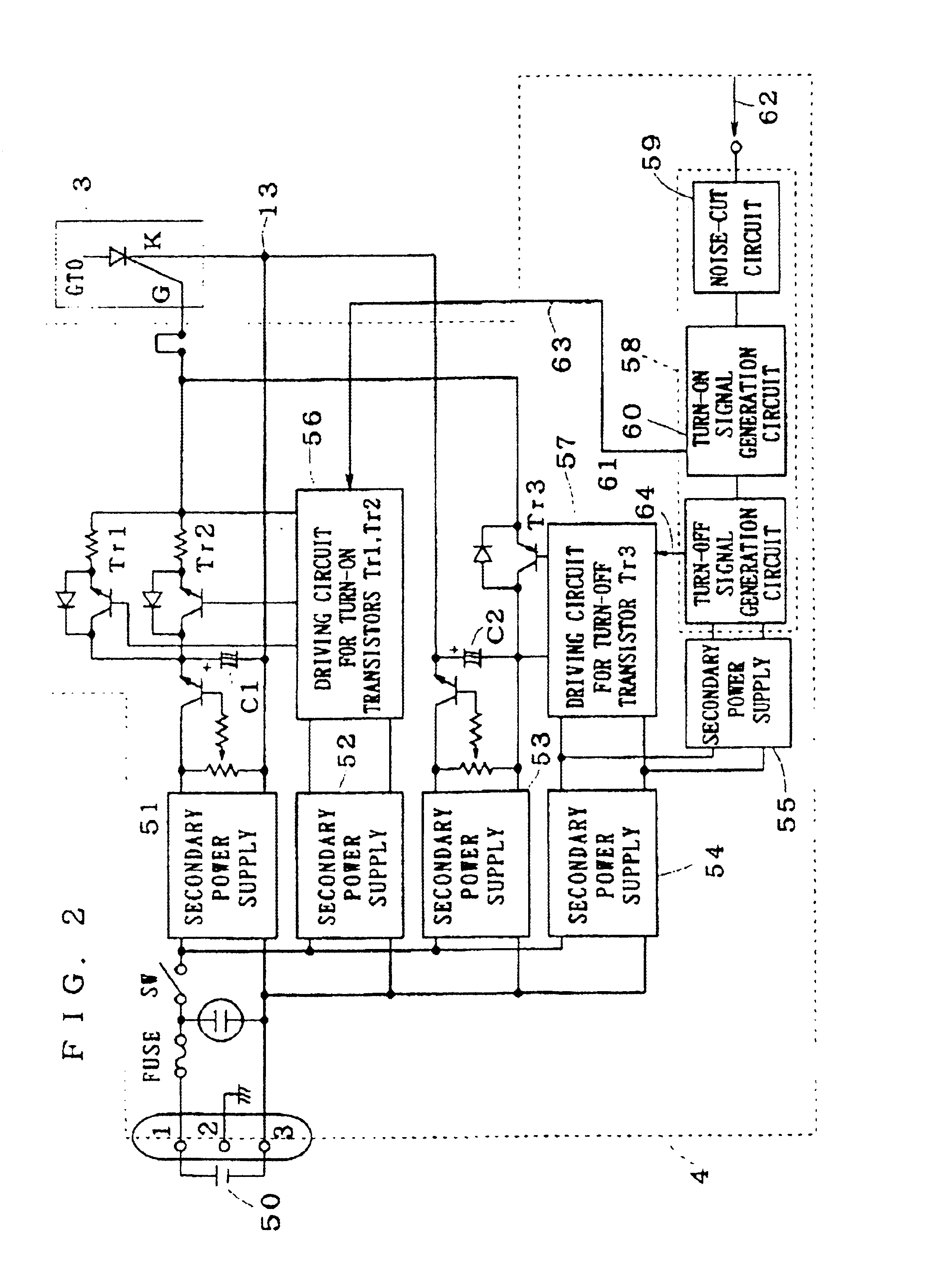

[0050]The point of the proposed new method of controlling the semiconductor switching element (or switching device) lies in that a main current flowing in the semiconductor switching element in an on-state is entirely commutated to a driving circuit, to thereby bring the semiconductor switching element into a turn-off state.

[0051]A gate turn-off thyristor (hereinafter referred to as “GTO”) will be discussed as an example of the semiconductor switching element. In this case, the first, second and third electrodes of the GTO correspond to an anode electrode, a cathode electrode and a gate electrode, respectively. The semiconductor switching element is not limited to the GTO of a quadruple layered structure, but may be a transistor of a triple layered struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com