Methods and devices to design and fabricate surfaces on contact lenses and on corneal tissue that correct the eye's optical aberrations

a technology of corneal tissue and contact lens, which is applied in the field of methods and devices to design and fabricate surfaces on contact lenses and on corneal tissue that correct the eye's optical aberration, and achieves the effect of improving the vision of patients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

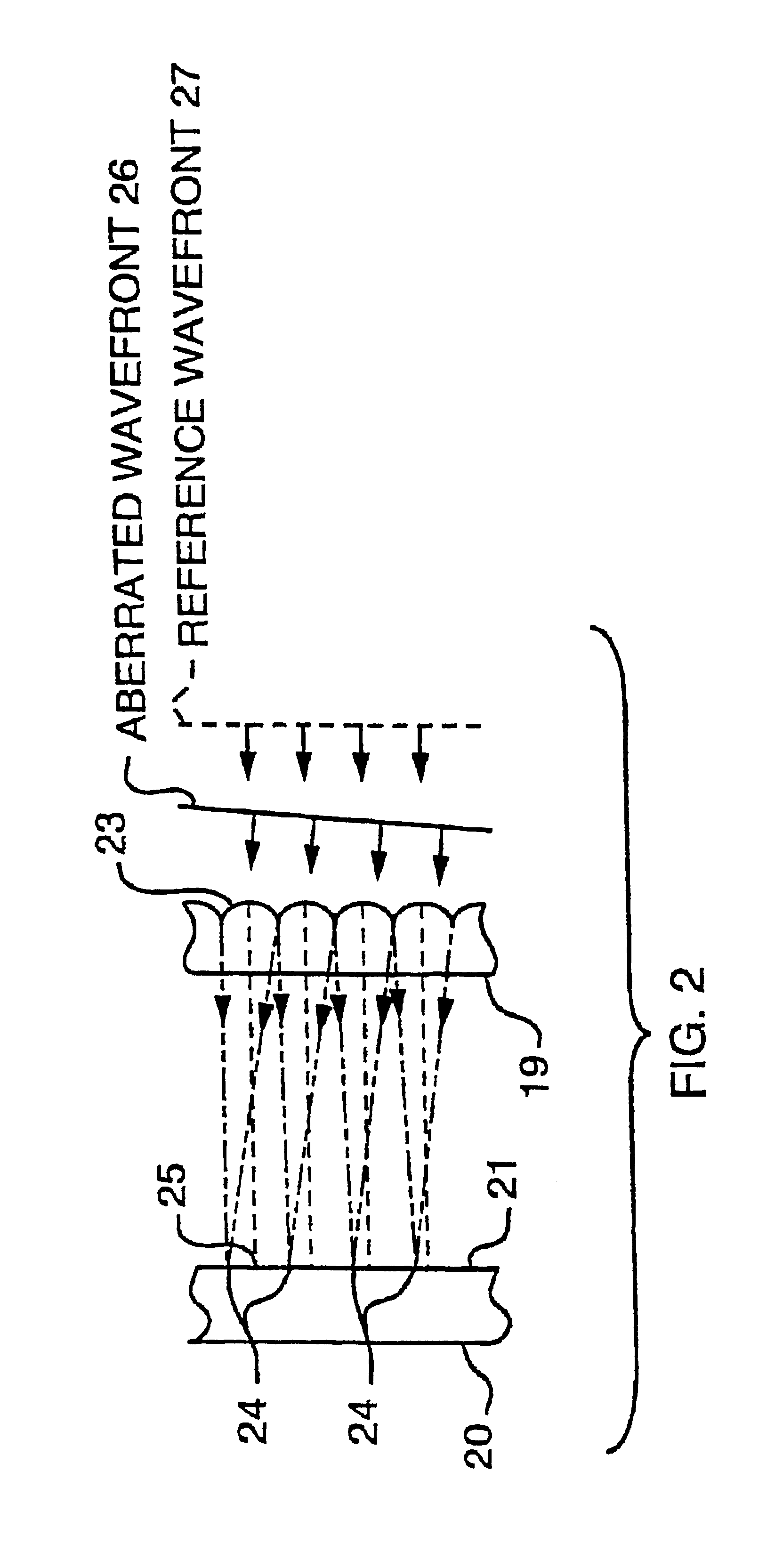

[0024]4.1 Wavefront Sensor for Measuring the Eye's Optical Aberrations

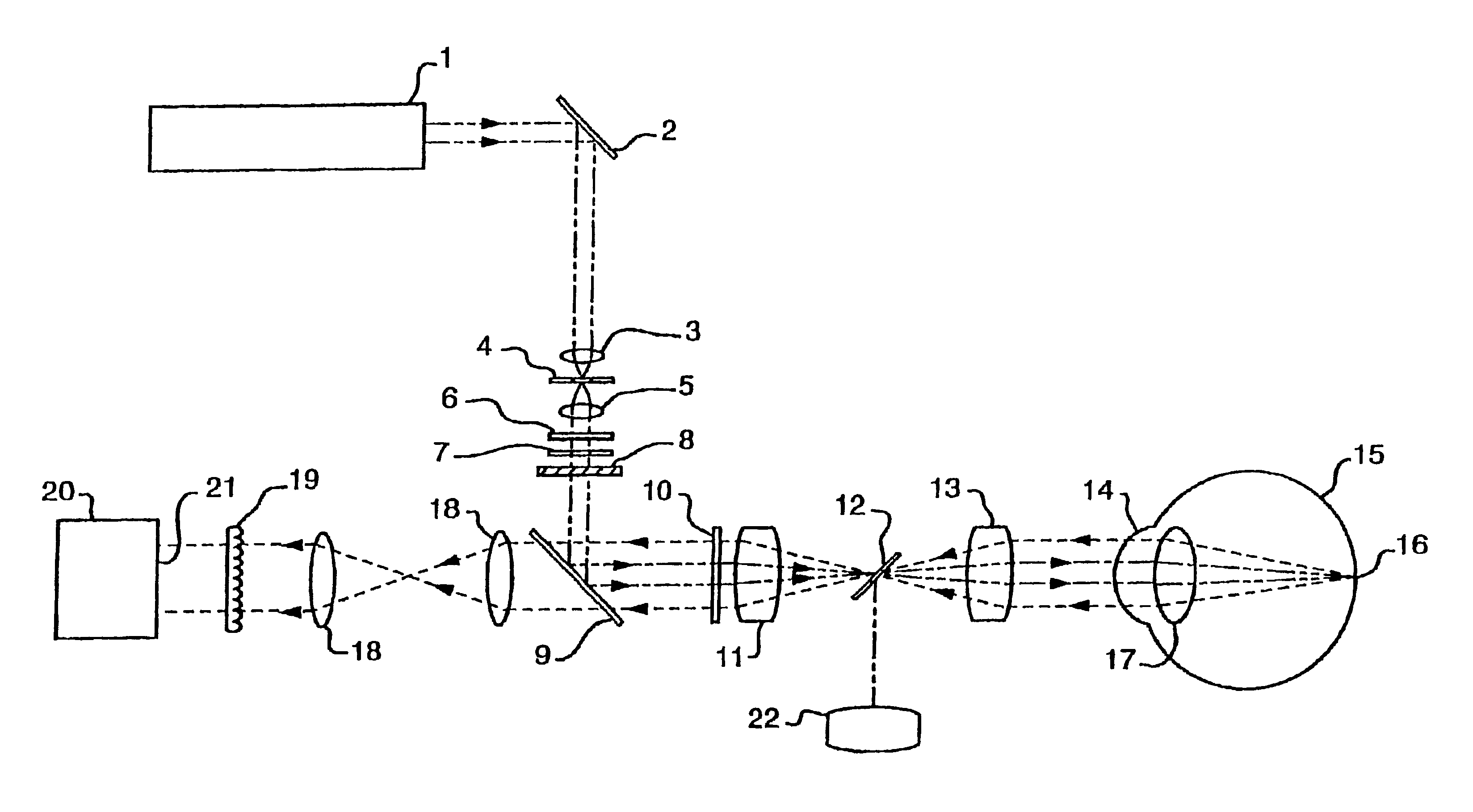

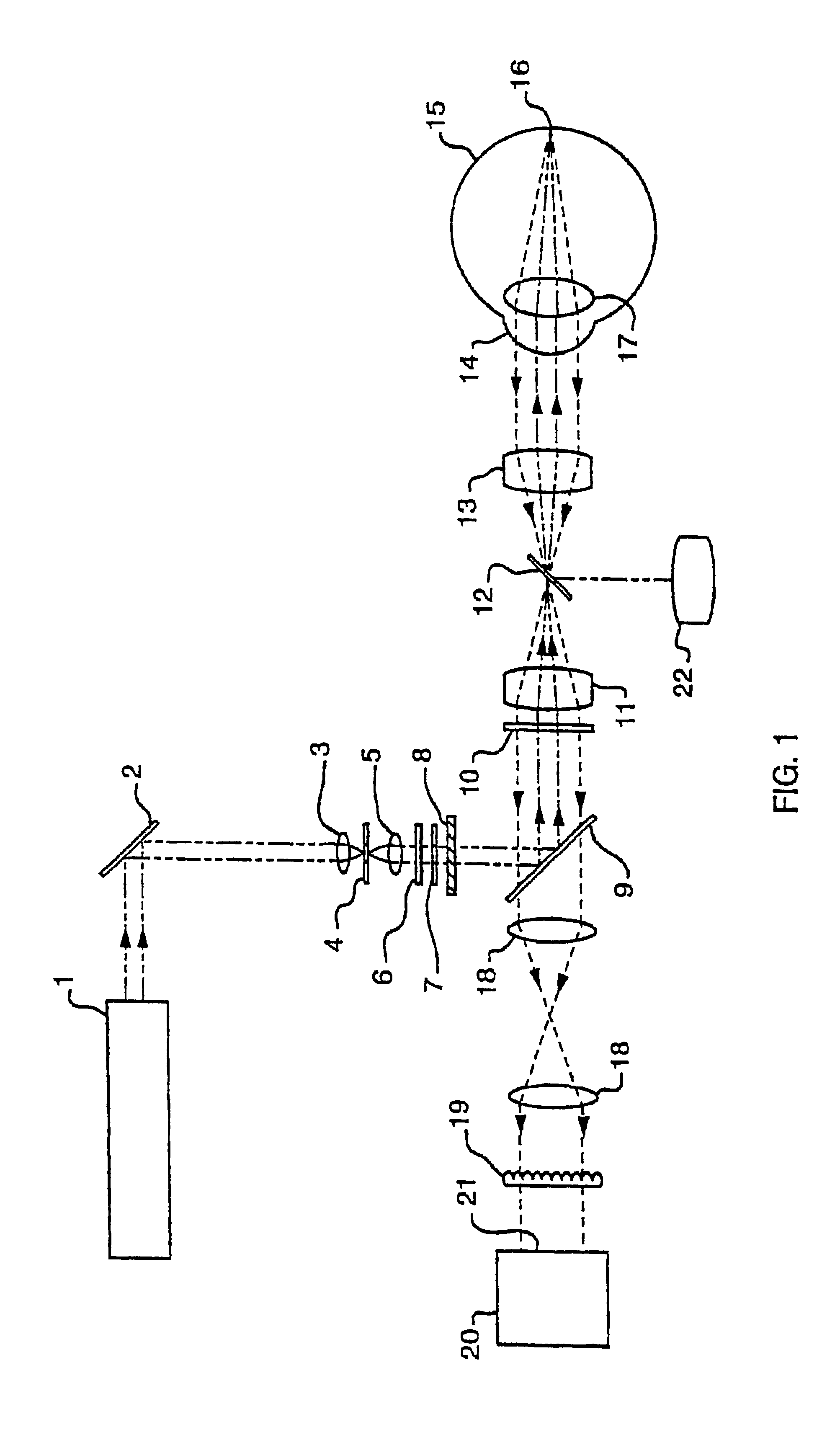

[0025]A schematic drawing of a wavefront sensor which has been modified to measure the eye's optical aberrations is shown in FIG. 1. The design and operating principles of the subassemblies of the wavefront sensor are explained in detail below.

[0026]4.1.1 Projection System

[0027]In order to reduce bothersome “speckle” from coherence effects from conventional laser sources, non-coherent optical sources are preferred. Thus, source 1 can be anyone of the following: laser diode operating below threshold, light emitting diode, arc source, or incandescent filament lamp. The source beam is deflected by fold mirror 2, and focused by microscope objective lens 3 onto a small pinhole aperture 4 having a diameter typically in the range from 5 to 15 microns. Another lens 5 collimates the beam which next passes through polarizer 6 and then through aperture stop 7. Typically this stop restricts the beam diameter to about 2 mm or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com