Phenylethylene-isoprene/butadiene-phenylethylene ternary block copolymer and its preparation method

A polystyrene block and ternary block technology, applied in the direction of adhesives, etc., can solve the problems of increased energy consumption, increased polymerization costs, and increased equipment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] In the process for the preparation of the ternary block copolymers of the present invention, the first step involves anionic polymerization of styrene at high monomer concentrations in the presence of polar additives. The initiators used in the polymerization are commonly used initiators in the field of anionic polymerization, such as lithium-based anionic initiators, specifically n-butyllithium, 1,4-dibutyllithium, sec-butyllithium, naphthalenelithium, ethyllithium, alkene Polylithium, preferably n-butyllithium, sec-butyllithium or mixtures thereof. In this step, the amount of initiator used should make the number average molecular weight of the polystyrene block obtained after the first step polymerization reaction is completed be 1000-5 × 10 4 , preferably 10 4 -3×10 4 . The polar additive used in this step may be an oxygen-, nitrogen-, sulfur-, or phosphorus-containing compound or a mixture thereof; specific examples thereof are diethyl ether, dibutyl ether, tetr...

Embodiment 1

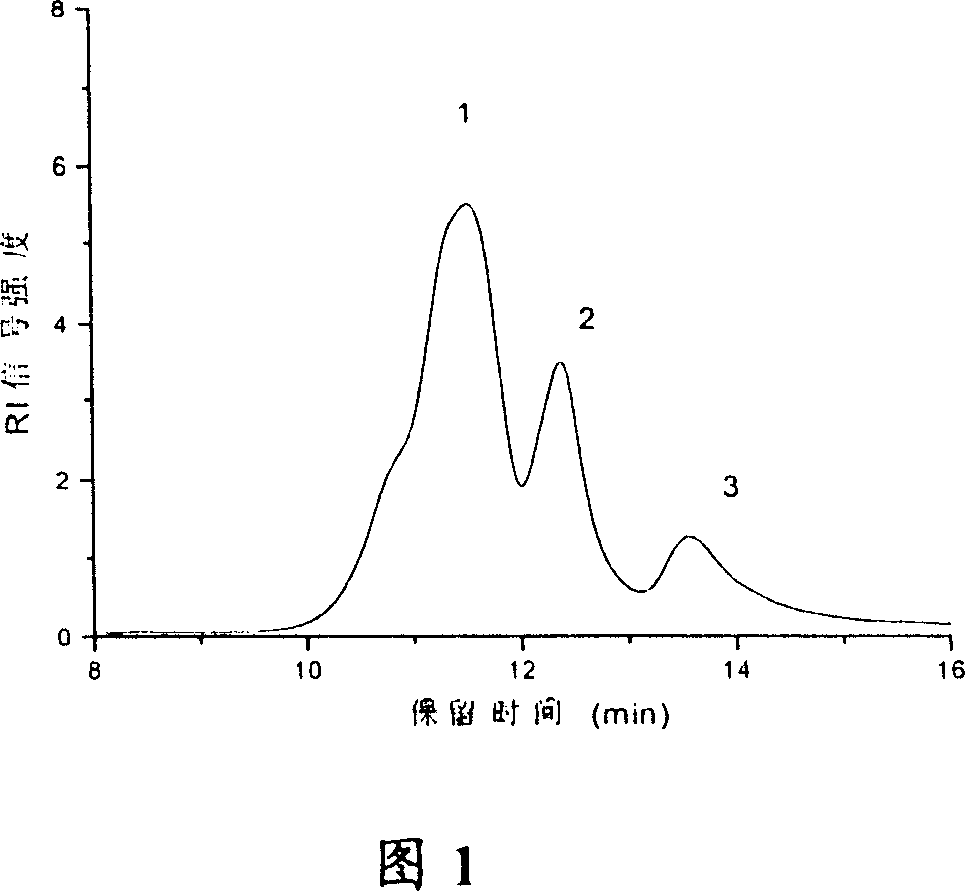

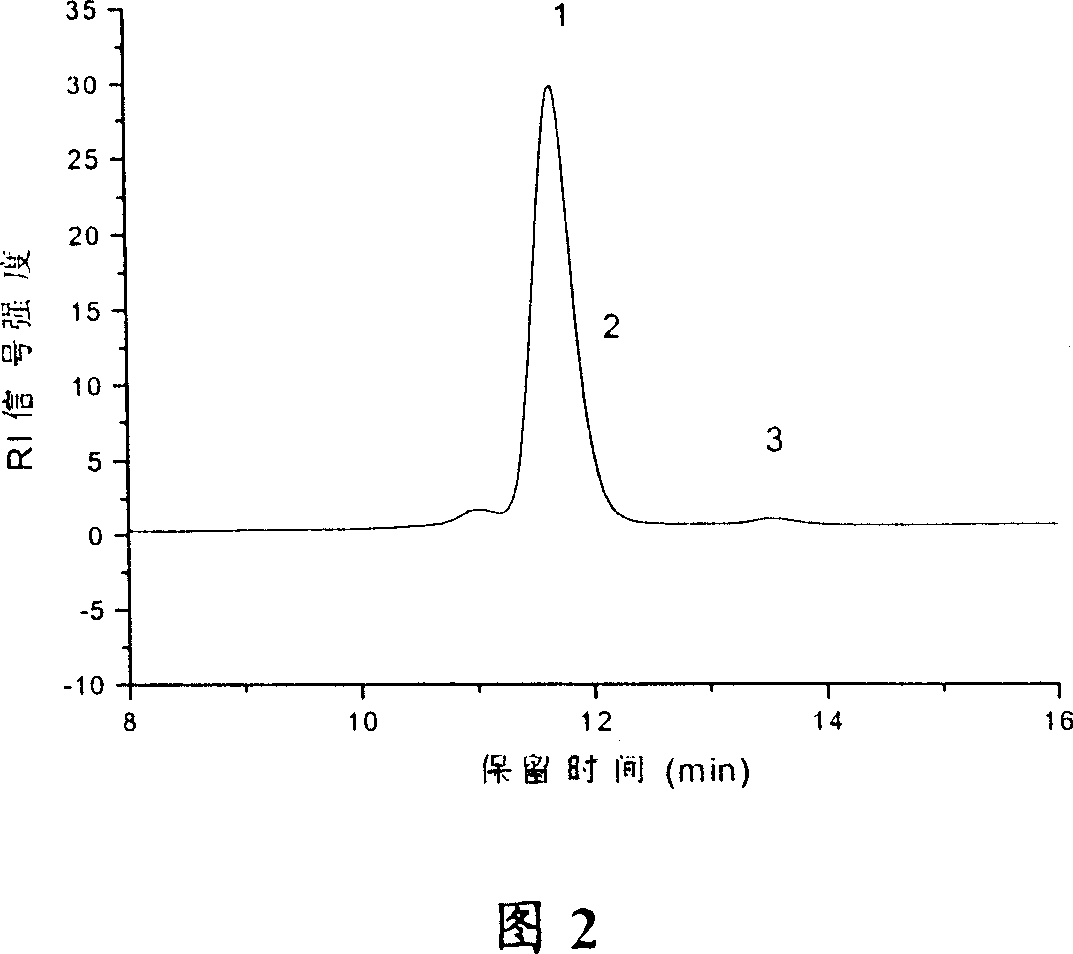

[0038] In a 5-liter stainless steel stirred tank, add 500 milliliters of cyclohexane, 100 grams of styrene, 2 milliliters of diluted tetrahydrofuran (tetrahydrofuran: cyclohexane = 30:70, by weight), and add 0.4M 30 milliliters of n-butyllithium initiator (the solvent is cyclohexane), reacted for 15 minutes, and the maximum temperature of the system reached 67°C. Open the valve of butadiene, isoprene and hexanaphthene solvent feeding tank simultaneously, add each 250 grams of butadiene and isoprene, 2900 milliliters of solvent hexanaphthene, control feeding and finish in 50 minutes. Add butadiene and isoprene in equal proportions and at equal speeds. During the polymerization process, the maximum temperature of the system reached 78° C., and 100 g of styrene was added after staying for 50 minutes. Continue the reaction for 50 minutes by adding 1 ml of isopropanol terminator. The obtained glue was added with anti-aging agent Irganox 1520 in an amount of 0.12% by weight of the...

Embodiment 2

[0040] In a 5-liter stainless steel stirred tank, add 700 milliliters of cyclohexane, 150 grams of styrene, 2 milliliters of diluted tetrahydrofuran (tetrahydrofuran: cyclohexane = 30:70, by weight), and add 0.4M 30 ml of n-butyllithium initiator (solvent is cyclohexane), reacted for 15 minutes, and the maximum temperature of the system reached 70°C. Simultaneously open the valve of butadiene, isoprene and cyclohexane solvent feeding tank to add 200 grams each of butadiene and isoprene, and 2900 milliliters of solvent cyclohexane, and the controlled feeding is completed in 50 minutes. Add butadiene and isoprene in equal proportions and at equal speeds. During the polymerization process, the maximum temperature of the system reached 82° C., and 150 g of styrene was added after staying for 50 minutes. Continue the reaction for 50 minutes by adding 1 ml of isopropanol terminator. The obtained glue was added with anti-aging agent Irganox 1520 in an amount of 0.12% by weight of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com