Thermal insulation aluminium light wall

A light-weight wall and thermal insulation board technology, which is applied in thermal insulation, walls, climate change adaptation, etc., can solve the problems of increasing the indoor usable area of buildings, wasting the outer surface of the wall, and poor thermal insulation effect, etc., and achieves good Practicality and economy, increase the indoor use area, good self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

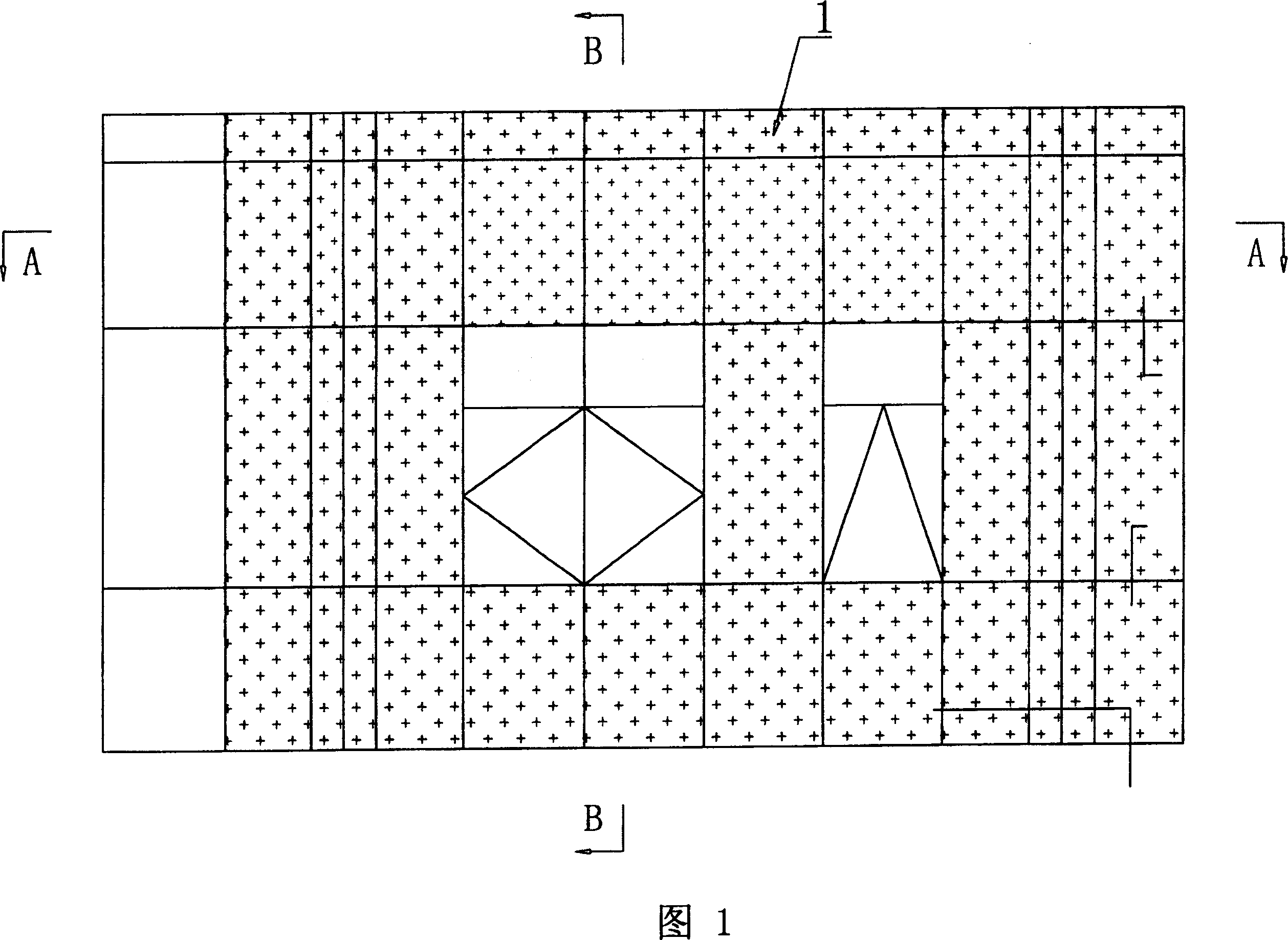

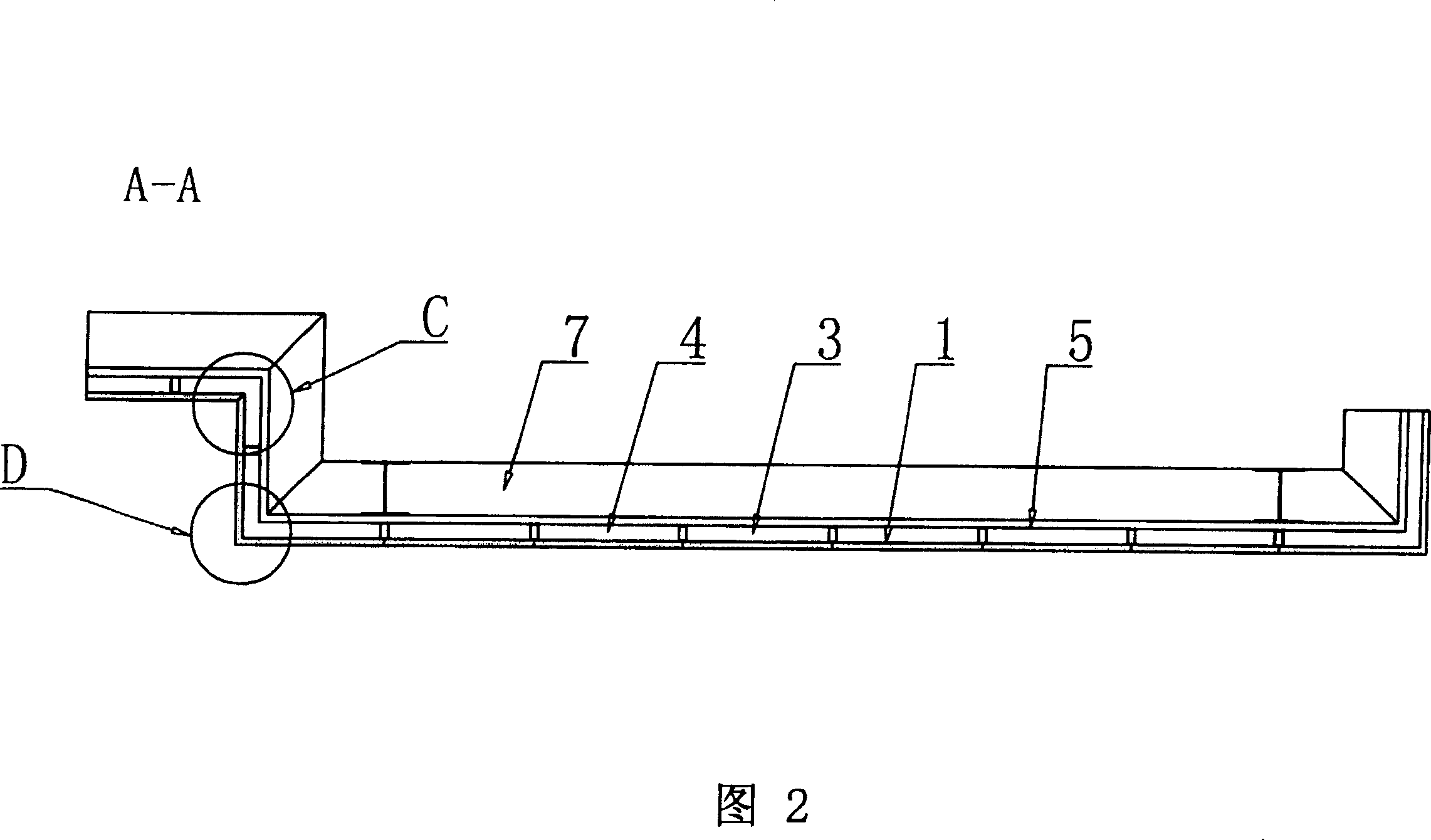

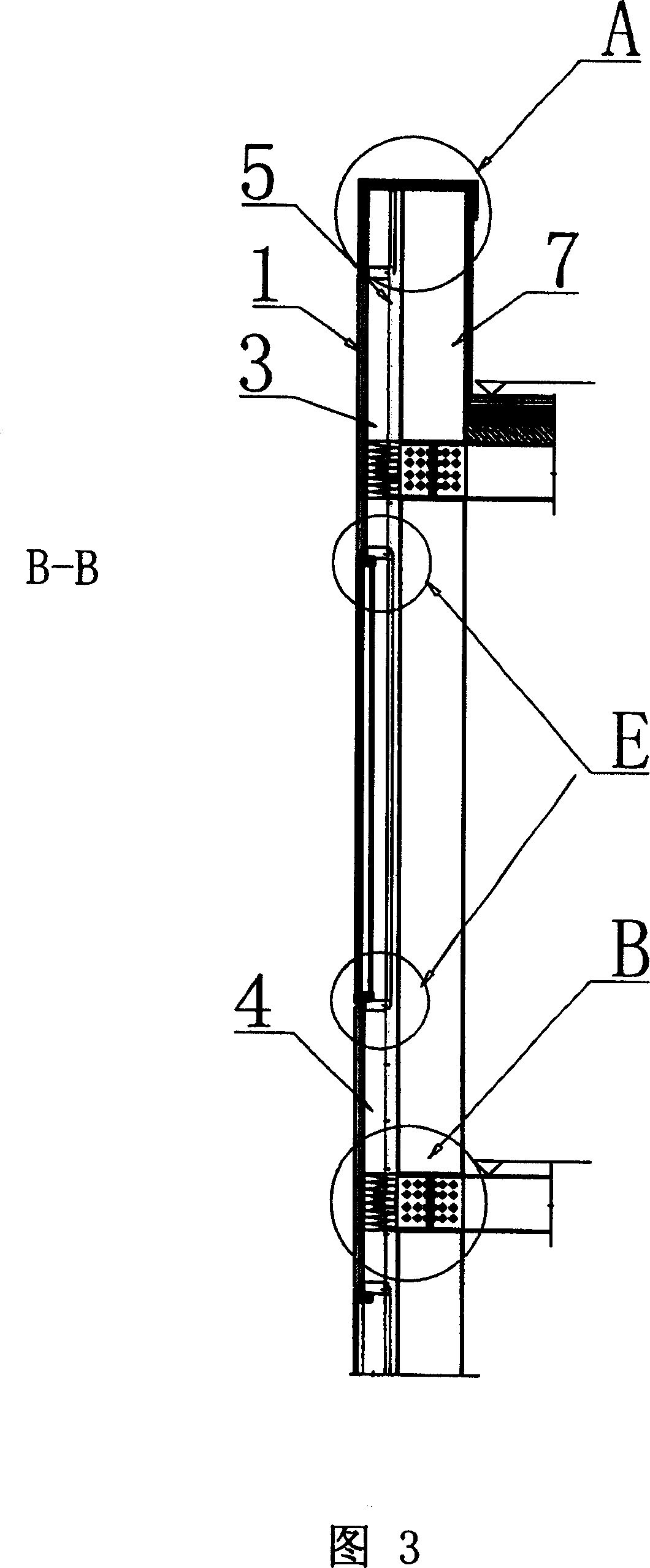

[0023] Referring to the accompanying drawings, the basic structure of the present invention includes a thermal insulation board 1, a metal keel 4, an interior decoration board 5, a fireproof insulation layer 3 and a main structure 7, and the thermal insulation board 1 is fixed on the metal keel (including the longitudinal keel 4) as the outer layer of the wall. And transverse keel 8) outside, in the inner side of this metal keel, interior decoration board 5 is fixed, between the keel between heat preservation board 1 and interior decoration board 5, fill fire-proof insulation layer 3. The metal keel is fixed with the main structure 7 . Its main structure 7 is steel structure, also can be the structure of other materials (such as reinforced concrete).

[0024] The thermal insulation board 1 is composed of an outer aluminum plate 16 and a polyurethane foam layer 17 compounded on its inner side (see FIG. 11 ), and an aluminum foil or an aluminum veneer panel 2 is attached to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com