Method of fixing tripyridyl ruthenium on electrochemical electrode surface

A technology of ruthenium terpyridine and electrode surface, applied in the direction of material electrochemical variables, etc., can solve the problems of cumbersome layer-by-layer assembly, less fixed amount, slow mass transfer of Nafion membrane, etc. The method is simple and easy to achieve, with good application prospects, The effect of good stability and electrochemiluminescent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

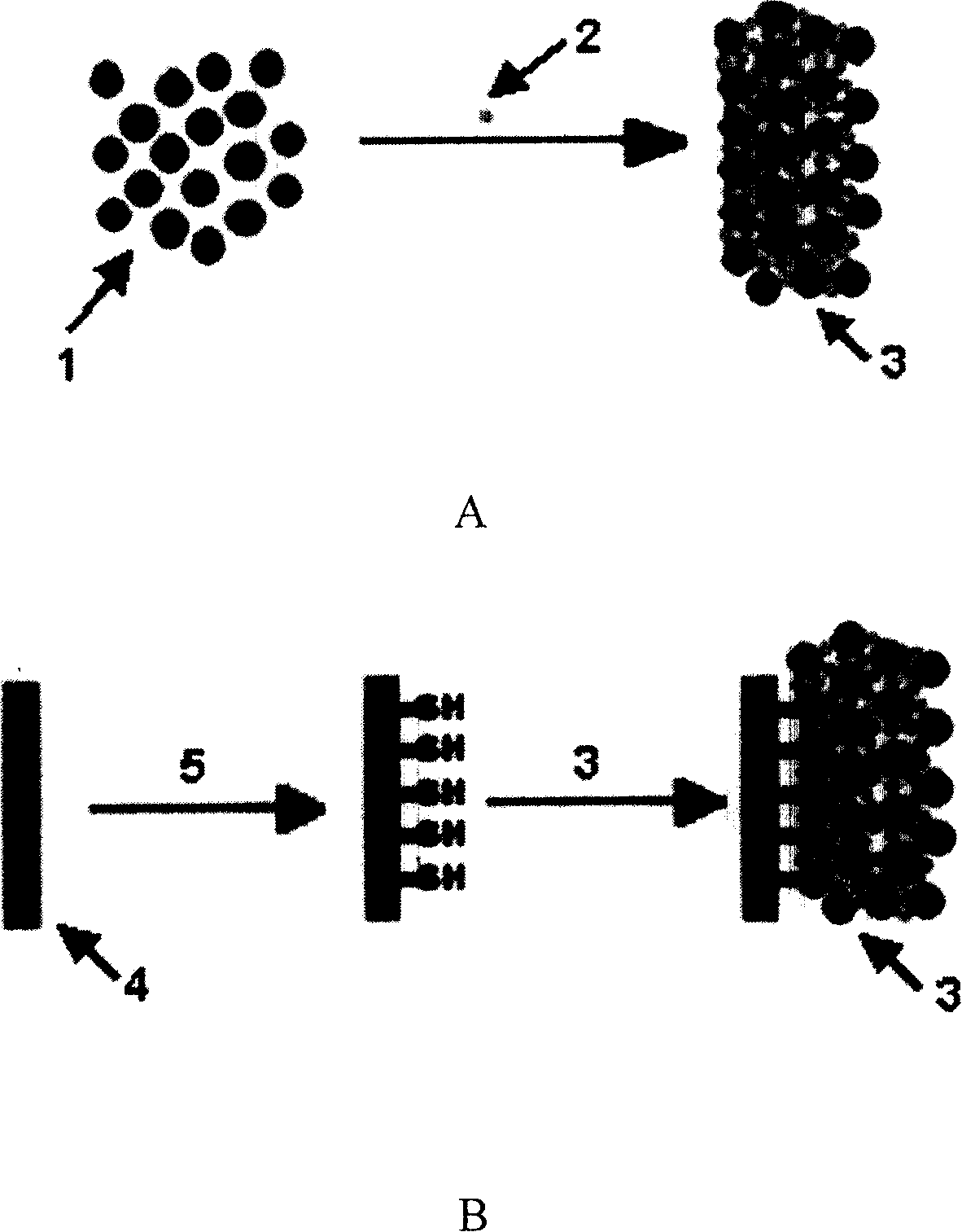

[0009] 100 μL of Ru(bpy) at a concentration of 10 mM 3 2+ Aqueous solution (0.001mmol) and 1 mL concentration of 0.3mM citrate anion-protected gold nanoparticle aqueous solution (0.0003mmol) were mixed in a small beaker at a molar ratio of 1:0.3 to obtain a large amount of aggregate suspension; The gold electrode was placed in an ethanol solution of 10% (volume percentage) mercaptopropyltriethoxysilane or dimercapto reagent for 10 hours, then taken out and dried to obtain a mercapto functionalized electrode surface; the aggregate was added dropwise 5 μL of the suspension was placed on the surface of a conductive glass electrode surface sulfhydrylated and placed at room temperature for 0.5 hours to prepare a surface with Ru(bpy) 3 2+ - Noble metal nanoparticle film modified electrodes.

Embodiment 2

[0011] 100 μL of Ru(bpy) at a concentration of 10 mM 3 2+ Aqueous solution (0.001mmol) and 10mL concentration of 0.3mM citrate anion-protected gold nanoparticle aqueous solution (0.003mmol) were mixed in a small beaker at a molar ratio of 1:3 to obtain a large amount of aggregate suspension; Place the noble metal electrode in the ethanol solution of 10% by volume mercaptopropyltriethoxysilane or dimercapto reagent for 10 hours, then take it out and dry it to obtain a mercapto-functionalized electrode surface; add this aggregate 25 μL of the suspension was placed on the surface of the surface thiolated gold electrode and placed at room temperature for 2 hours to prepare the surface with Ru(bpy) 3 2+ - Noble metal nanoparticle film modified electrodes.

Embodiment 3

[0013] 100 μL of Ru(bpy) at a concentration of 10 mM 3 2+ Aqueous solution (0.001mmol) and 3.3mL concentration are the silver nanoparticle aqueous solution (0.001mmol) that the citrate anion protection of 0.3mM is mixed in the small beaker by the molar ratio of 1: 1, obtain a large amount of aggregate suspension; Or the noble metal electrode is placed in the ethanol solution of 10% by volume of mercaptopropyltriethoxysilane or dimercapto reagent for 10 hours, then taken out and dried to obtain a mercapto functionalized electrode surface; dropwise adding this aggregation 10 μL of the suspension of the body was placed on the surface of the conductive glass electrode surface thiolated and placed at room temperature for 1 hour, and the Ru(bpy) surface was prepared. 3 2+ - Noble metal nanoparticle film modified electrodes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com