Light-emitting element reception package, light-emitting device and lighting device

A technology of light-emitting elements and light-emitting devices, which is applied in the direction of electrical components, semiconductor devices, and electric solid-state devices. Effects that increase light output or brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

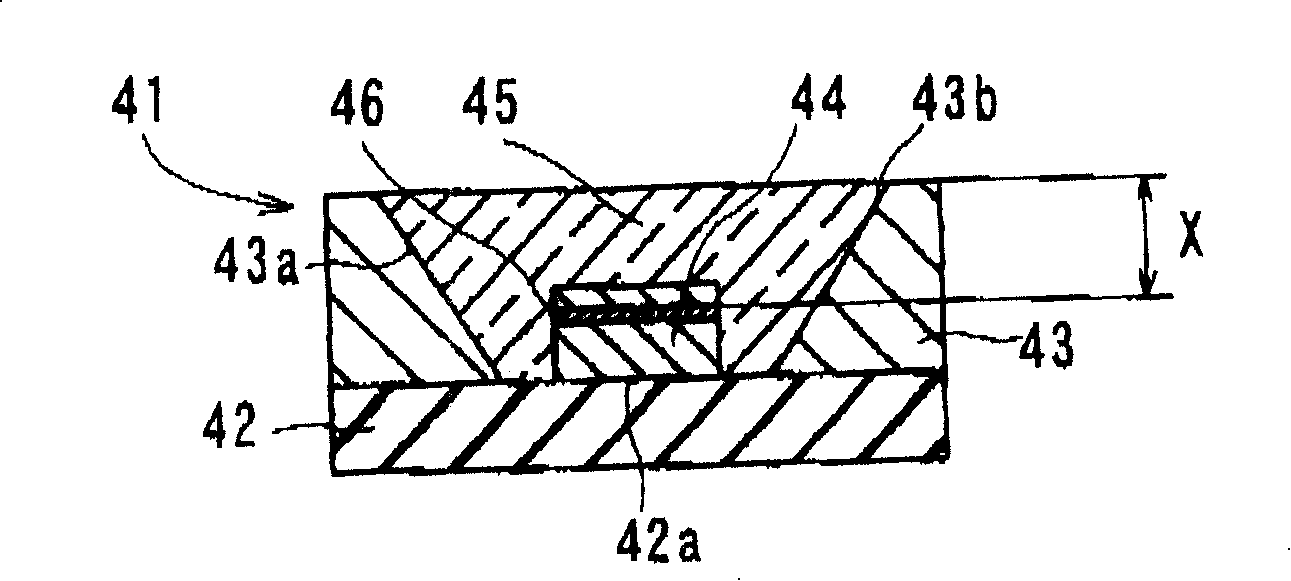

[0274] Examples of the light emitting device 41 according to the first embodiment of the present invention will be shown below.

[0275] First, an alumina ceramic matrix composed of crystal grains of various grain sizes to be the matrix 42 is prepared. Also, wiring conductors for electrically connecting the light emitting element 44 and an external circuit board via internal wiring formed inside the base body 42 are formed around the placement portion 42a where the light emitting element 44 is placed. Moreover, the metallization layer of the wiring conductor on the substrate 42 made of Mo-Mn powder is formed into a circular pad with a diameter of 0.1 mm, and its surface is sequentially coated with a Ni plating layer with a thickness of 3 μm and an Au plating layer with a thickness of 2 μm. In addition, the internal wiring inside the base body 42 is formed by an electrical connection portion constituted by a through-conductor, a so-called through-hole. The via holes are also m...

Embodiment 2

[0282] Next, a light-emitting device 41 having the same structure as that of the above-mentioned example and in which the average grain size of the ceramic crystal grains after sintering of the substrate 42 is 1 (μm), 5 (μm), and 10 (μm) was produced, and the relative light emission to the direction was measured. The full beam (light output) of the load current of the element 44. Furthermore, the light-emitting device 41 was installed in heat radiation equipment with the same cooling function everywhere, and the light output was measured with an integrating sphere. The result is as Figure 7 shown.

[0283] As shown in FIG. 27, when the rated current of the load current to the light-emitting element 44 is 20 (mA) and the rated voltage is 3.4 (V), a light-emitting device in which the average grain size of ceramic crystal grains is 1 (μm) The light output of 41 was 0.96 (lm), and the luminous efficiency was 14 (lm / W). In addition, the light output of the light emitting device...

Embodiment 3

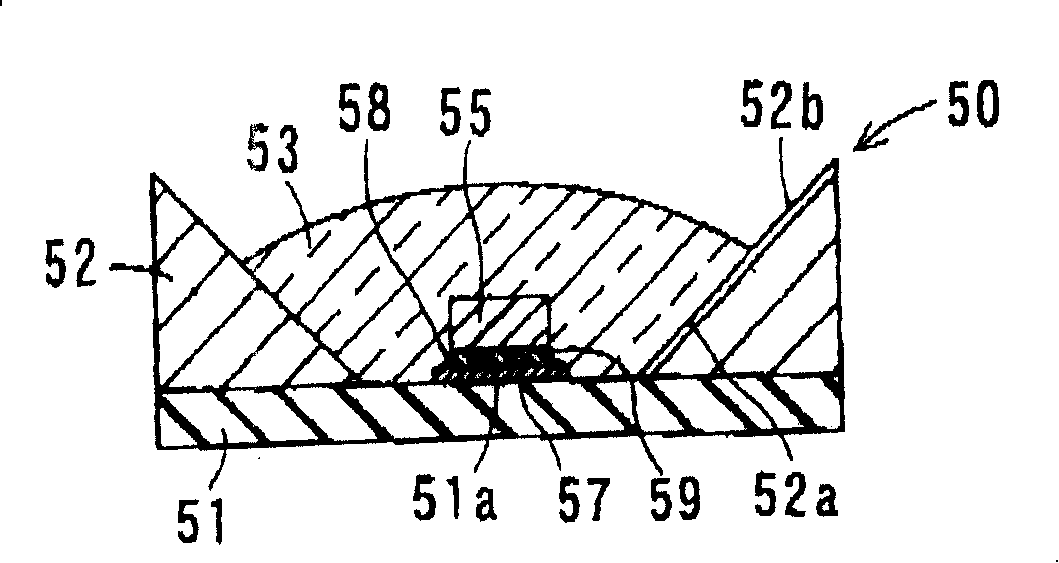

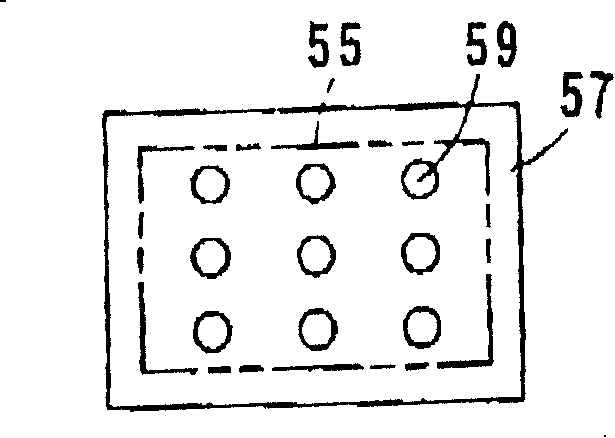

[0288] according to Figure 7 , for the light emitting device 60C of the sixth embodiment of the present invention, examples are shown below.

[0289] First, an alumina ceramic substrate to be the base body 61 is prepared. Furthermore, the base 61 is integrally formed with the convex portion 61b having the seating portion 61a, and the upper surface of the seating portion 61a is parallel to the upper surface of the base 61 at a location other than the seating portion 61a.

[0290] The base body 61 has a cylindrical convex portion 61b having a diameter of 0.4mm×thickness (various values) formed on the upper central portion of a cylindrical plate having a diameter of 0.8mm×thickness 0.5mm.

[0291] In addition, an electrical connection pattern for electrically connecting the light emitting element 65 and an external circuit board through internal wiring formed inside the base body 61 is formed on the mounting portion 61a of the convex portion 61b where the light emitting element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com