High-performance passive phase-change radiation system and its application

A heat dissipation system and passive technology, which is applied in cooling/ventilation/heating transformation, instruments, electrical digital data processing, etc., can solve the problems of limited heat dissipation capacity of passive cooling technology, inability to effectively improve the total heat transfer capacity, and critical heat flow constraints, etc. Achieve the effects of arbitrary heat transfer size, improved heat dissipation and cooling capacity, and large total heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

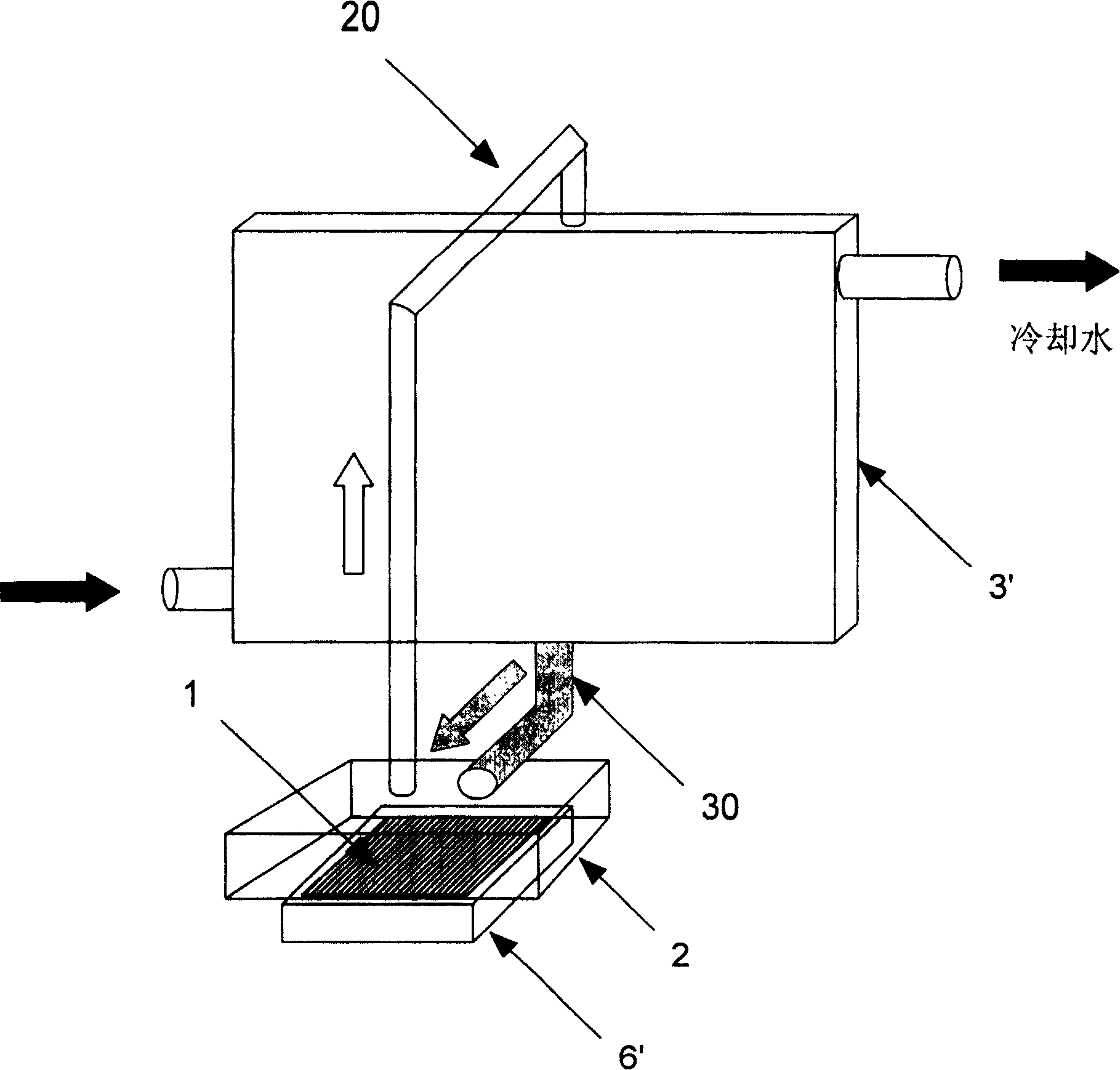

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0042] About the microgroove group evaporation heat exchange element in the present invention:

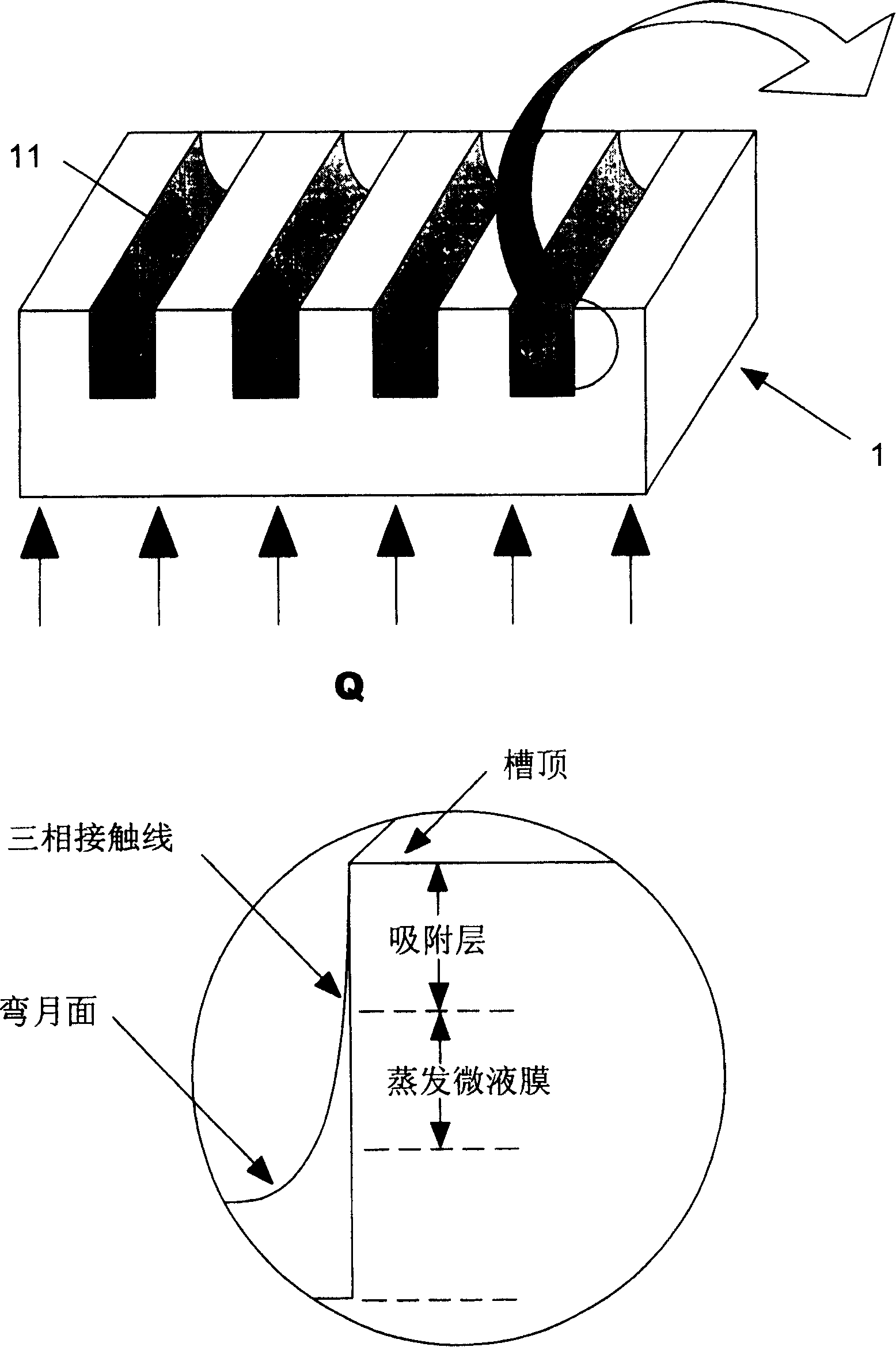

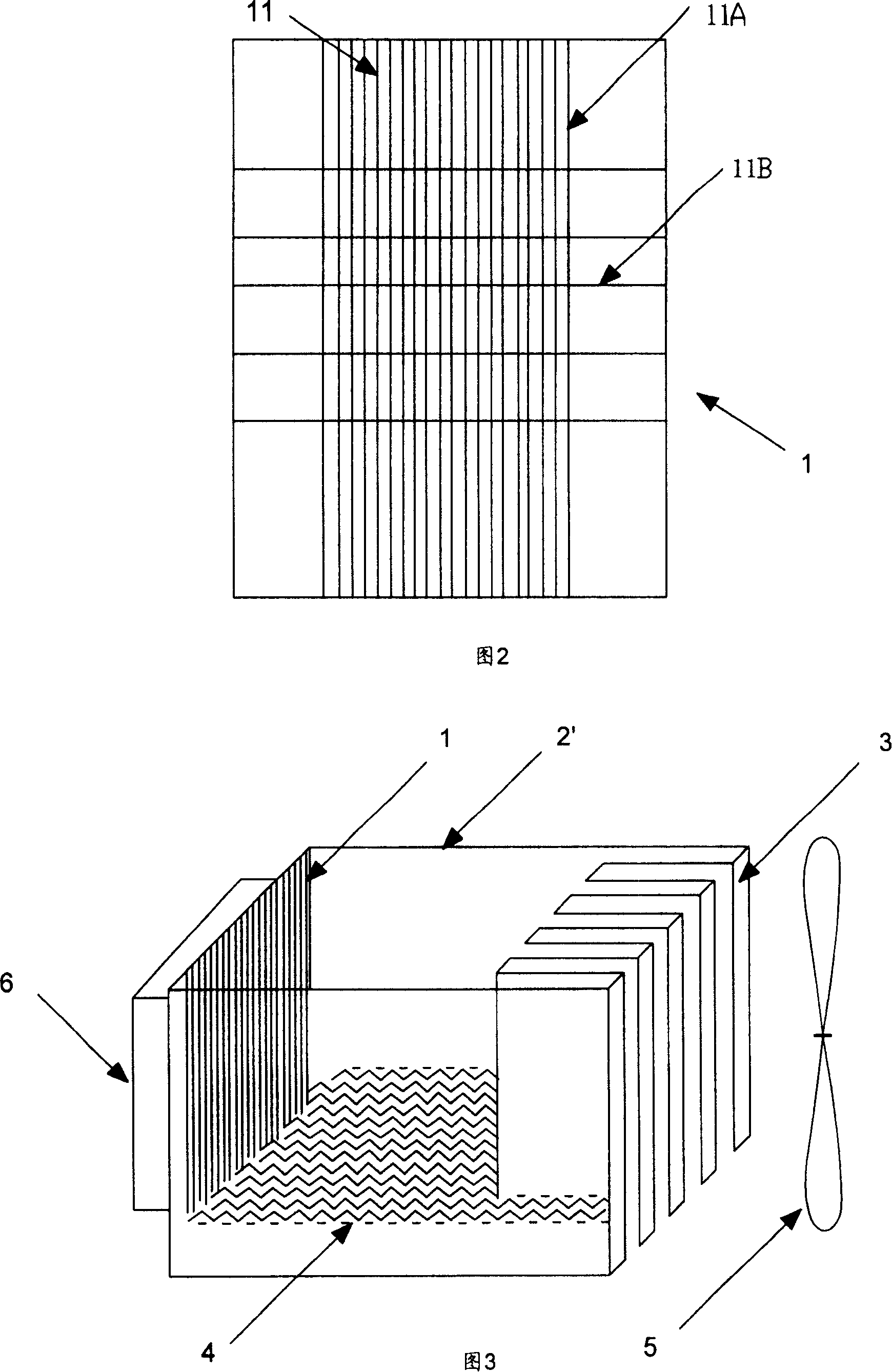

[0043] The micro-groove group evaporative heat exchange element generally refers to engraving dense fine straight grooves on a flat plate of any size, and the capillary force generated in the micro-grooves makes the liquid suck into the micro-grooves. The liquid in each tank has a tiny meniscus near the three-phase (gas, liquid, solid) contact line, and the evaporation of the meniscus has a great local heat transfer coefficient. By designing the optimal size and structure layout, its heat transfer may be higher than or several times the critical heat load of general pool boiling. And it has the characteristics of arbitrary heat transfer size and huge total heat transfer. Therefore, this heat exchange technology may have an important application prospect in the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com