Process for efficient removing organic pollutant in water by catalysis and ozonization

A technology of organic pollutants and ozone oxidation, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of incomplete elimination of pollution, secondary pollution of water, high treatment costs, etc., and achieve high The effect of practical application value, reduction of processing cost, and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

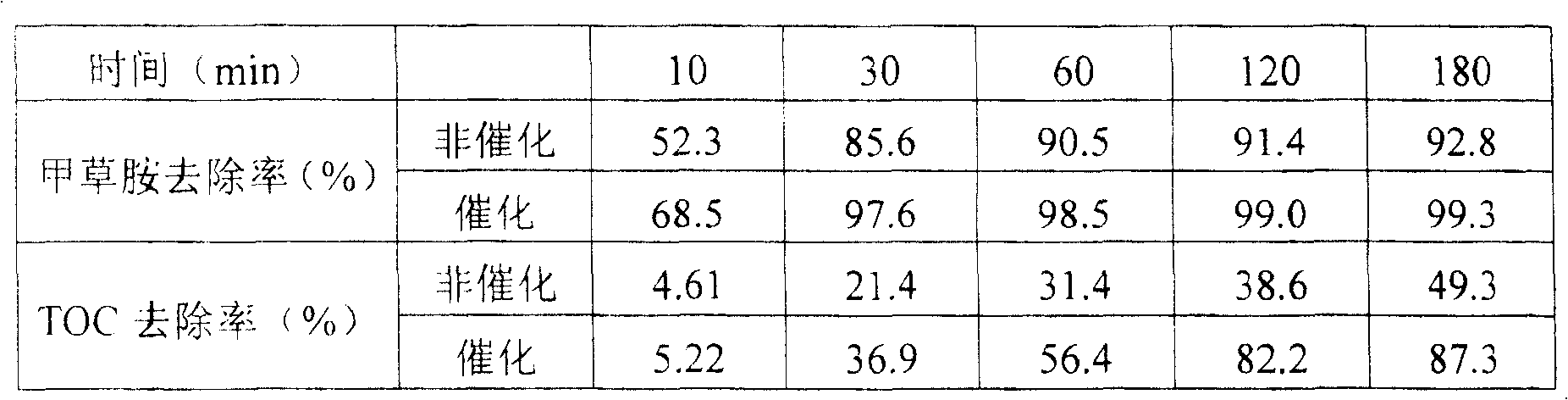

Embodiment 1

[0019] In the glass reactor that volume is 100ml, add alachlor solution 75ml, adjust O 3 Each parameter of the generator reaches the set value, and O is generated at a flow rate of 40ml / min. 3 , after the gas flow is stable for 2 minutes, the gas inlet of the reactor is connected, and the timing is started, and the oxidation reaction is carried out in an airtight manner, and this time is regarded as 0 time. Carry out catalytic ozonation treatment under the following conditions:

[0020] Reaction target solution volume: 75ml

[0021] Reaction target solution concentration: Alachlor: 100mg / L, TOC: 60mg / L

[0022] Reaction target solution temperature: 20°C

[0023] Reaction solution system: 0.001M phosphate buffer solution

[0024] Solution initial pH: 7.00

[0025] o 3 Occurrence concentration: 12.2mg / L / min

[0026] Catalytic material: a cylindrical material formed by catalyst powder loaded on the surface of a honeycomb ceramic body

[0027] Processing method: dynamic pr...

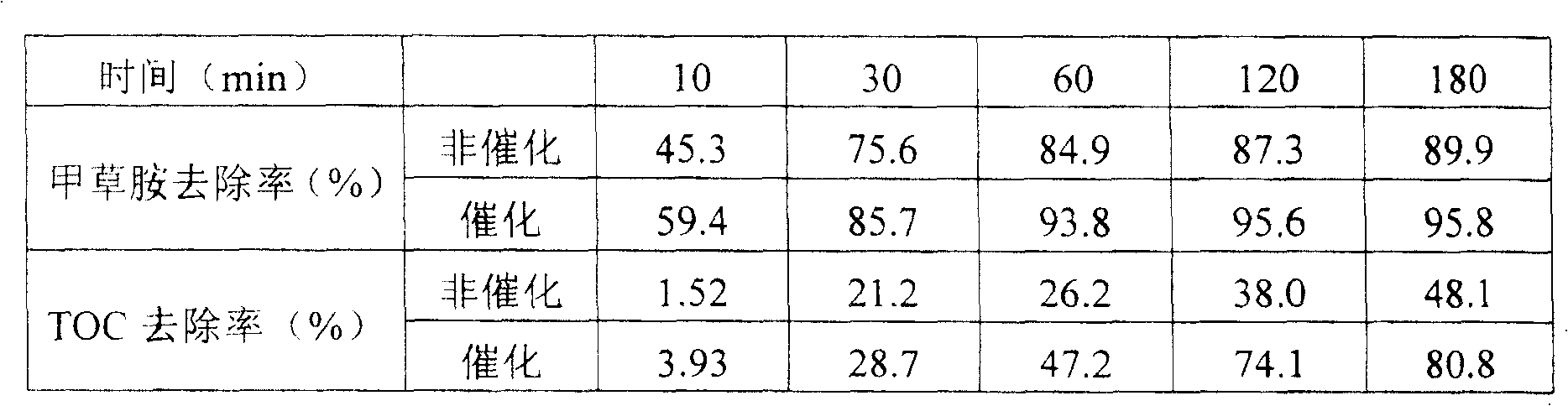

Embodiment 2

[0032] In the glass reactor that volume is 100ml, add alachlor solution 75ml, adjust O 3 Each parameter of the generator reaches the set value, and O is generated at a flow rate of 40ml / min. 3 , after the gas flow is stable for 2 minutes, the gas inlet of the reactor is connected, and the timing is started, and the oxidation reaction is carried out in an airtight manner, and this time is regarded as 0 time. Carry out catalytic ozonation treatment under the following conditions:

[0033] Reaction target solution volume: 75ml

[0034] Reaction target solution concentration: Alachlor: 100mg / L, TOC: 60mg / L

[0035] Reaction target solution temperature: 20°C

[0036] Reaction solution system: 0.001M phosphate buffer solution

[0037] Solution initial pH: 4.30

[0038] o 3 Occurrence concentration: 12.2mg / L / min

[0039] Catalytic material: a cylindrical material formed by catalyst powder loaded on the surface of a honeycomb ceramic body

[0040] Processing method: dynamic pr...

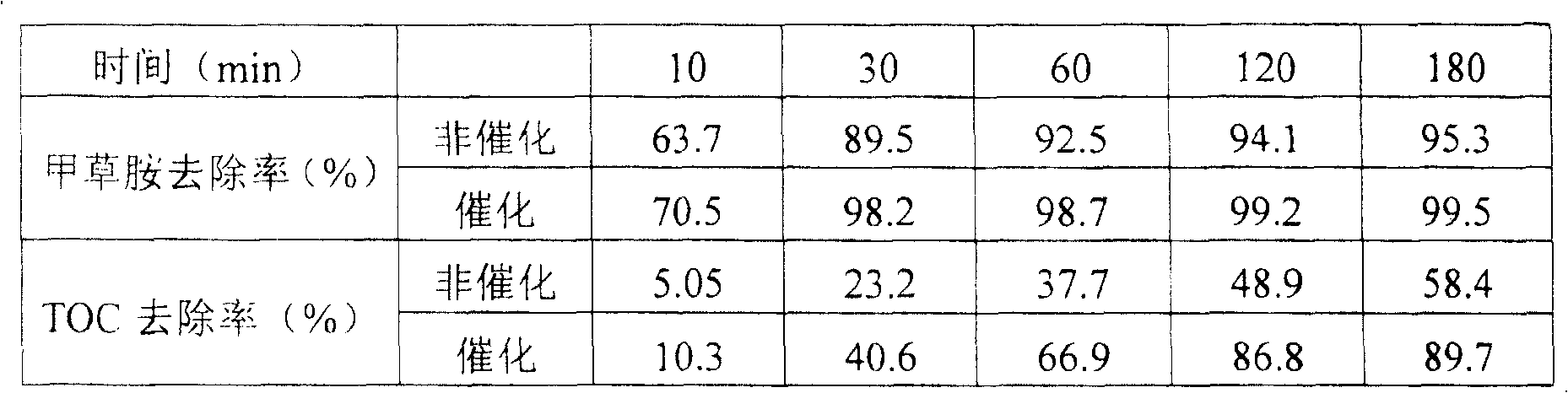

Embodiment 3

[0045] In the glass reactor that volume is 100ml, add alachlor solution 75ml, adjust O 3 Each parameter of the generator reaches the set value, and O is generated at a flow rate of 40ml / min. 3 , after the gas flow is stable for 2 minutes, the gas inlet of the reactor is connected, and the timing is started, and the oxidation reaction is carried out in an airtight manner, and this time is regarded as 0 time. Carry out catalytic ozonation treatment under the following conditions:

[0046] Reaction target solution volume: 75ml

[0047] Reaction target solution concentration: Alachlor: 100mg / L, TOC: 60mg / L

[0048] Reaction target solution temperature: 20°C

[0049] Reaction solution system: 0.001M phosphate buffer solution

[0050] Solution initial pH: 9.10

[0051] o 3 Occurrence concentration: 12.2mg / L / min

[0052] Catalytic material: a cylindrical material formed by catalyst powder loaded on the surface of a honeycomb ceramic body

[0053] Processing method: dynamic pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com