Line narrowing unit with flexural grating mount

A technology of fixing parts and gratings, applied in the field of lasers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

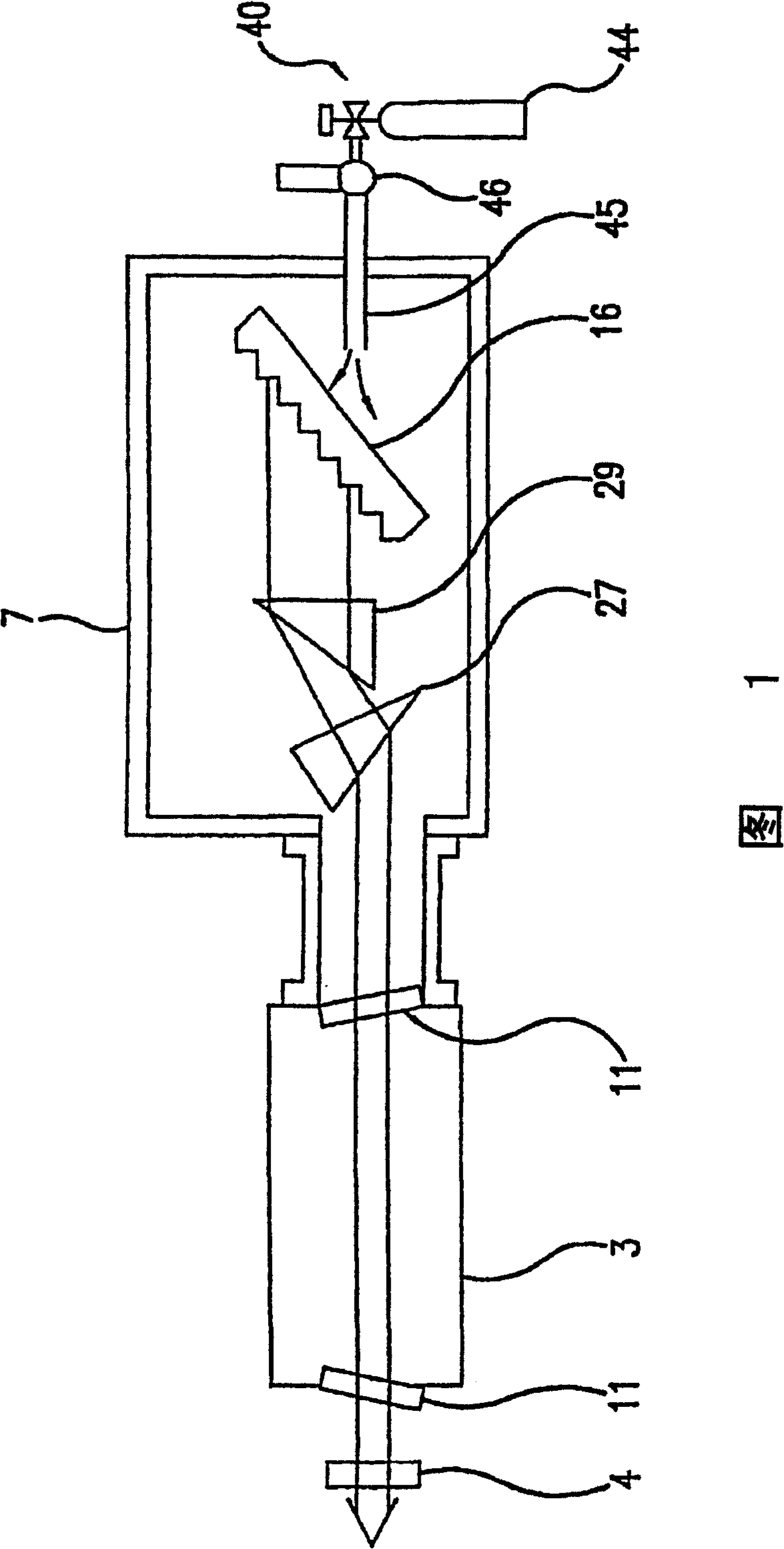

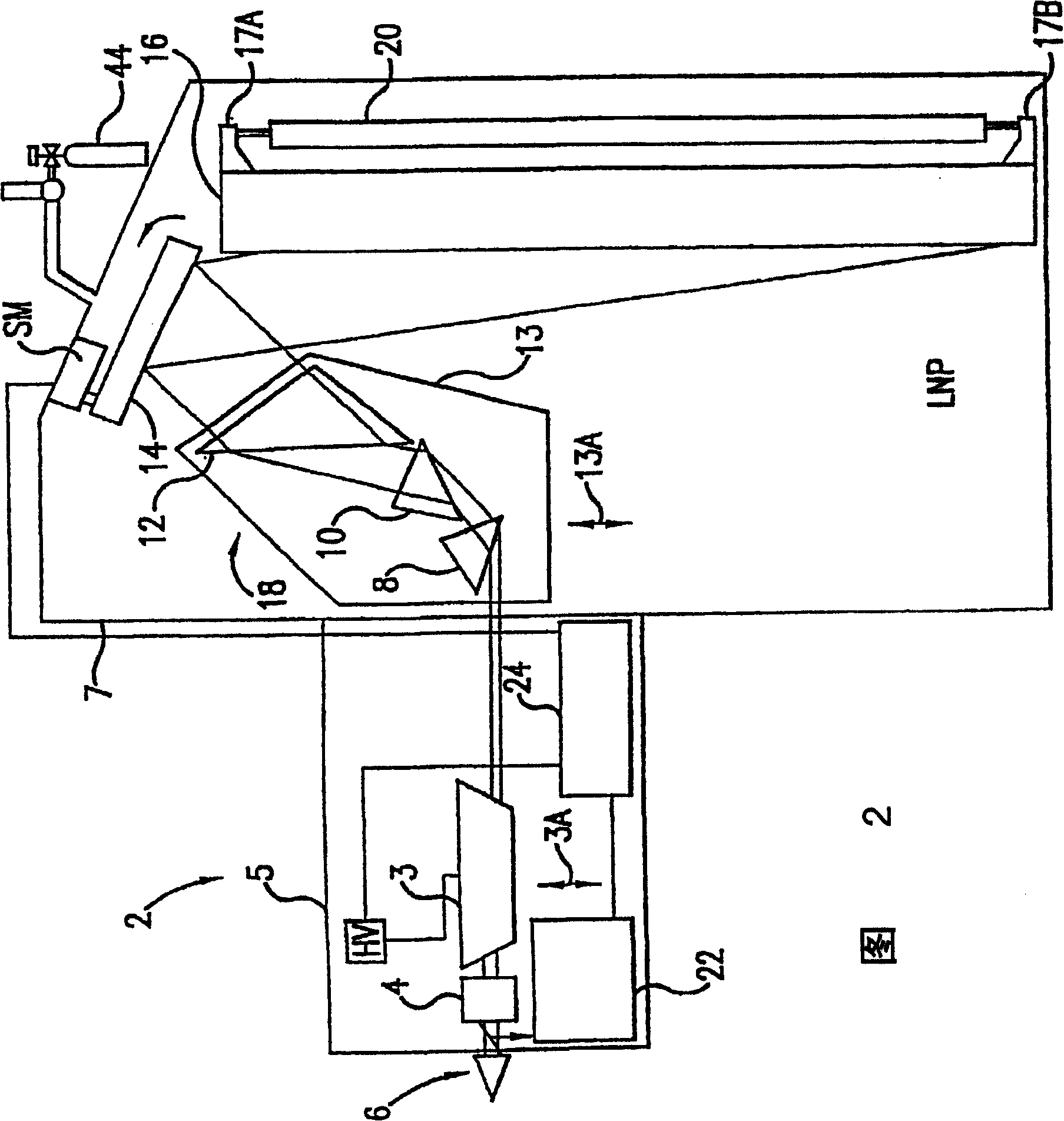

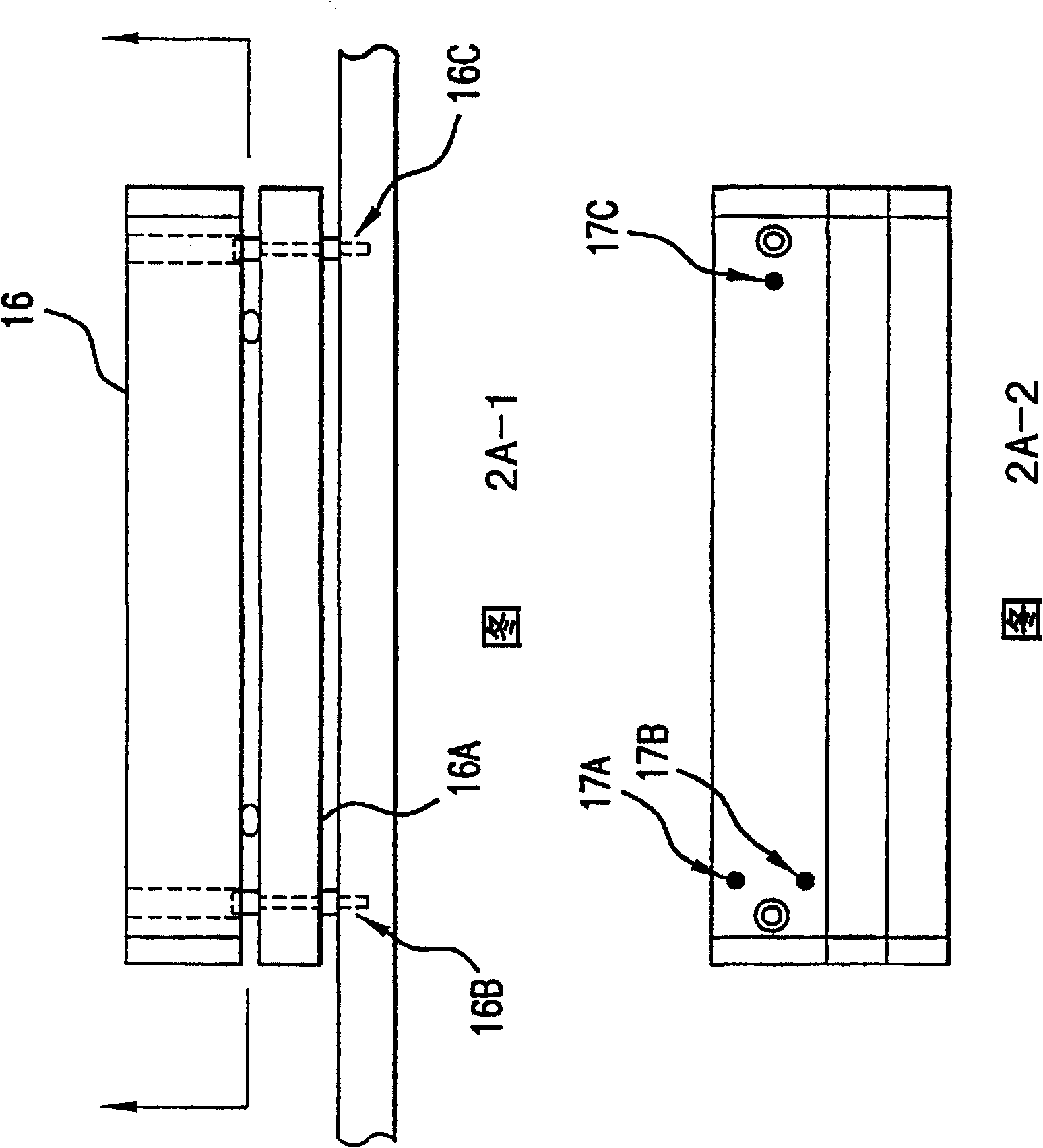

[0046] Preferred embodiments of the present invention will be described with reference to the accompanying drawings.

[0047] Laser performance at high average power

[0048] A prior art beam-narrowed KrF excimer laser operating at relatively low average power, typically less than 5 watts, typically produces a laser centered at about 248 nm with a bandwidth of less than 0.6 picometers bundle. As long as the average power is below 5 Watts, the laser can be operated without problems at high repetition rates up to 2000 Hz or more. Typical pulse energies for lithographic KrF excimer lasers are 10 mJ. Therefore, to avoid increasing the average power, the laser must operate at a lower duty cycle. For example, it may be run at 2 kHz in bursts of 200 pulses with about 0.45 seconds between bursts. Such an operating state will produce the following average power:

[0049]

[0050] Problems with bandwidth control start to show up when the average power increases. This happens, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com