Methods for planarization of dielectric layer around metal patterns for optical efficiency enhancement

An image sensor and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as substrate parallelism, pattern drop, reduced sensor performance, etc., to reduce refraction, eliminate Non-uniform thickness, the effect of improving optical sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

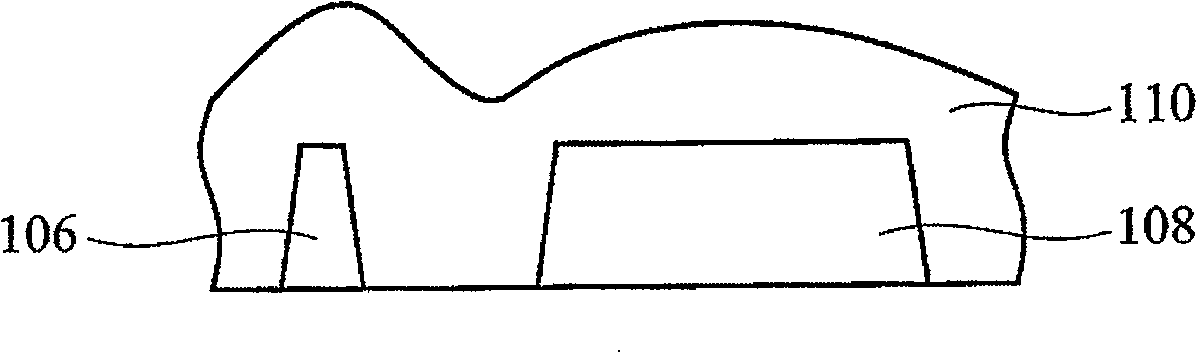

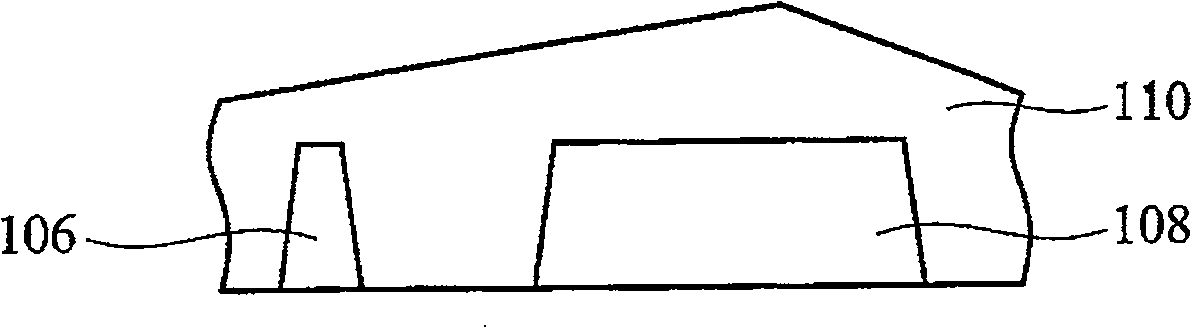

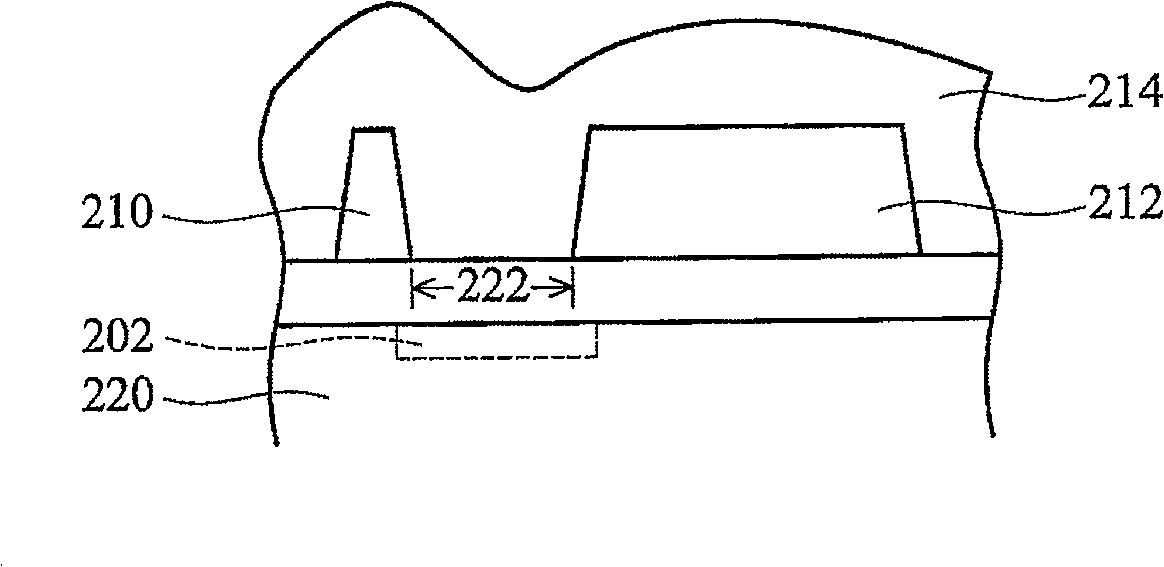

[0022] Please refer to Figure 2A to Figure 2D , which illustrates a manufacturing process for processing a dielectric layer according to a first embodiment of the present invention. This flow shows a method to uniformly planarize the surface of the dielectric layer, which is the four steps described in one embodiment for this purpose.

[0023] Please refer to Figure 2A , the metal layers 210 and 212 are used to block electromagnetic radiation in the optical wavelength range, especially light radiation. The metal layers 210 and 212 are metal patterns, and the whole can be formed into a metal pattern, which can be formed by plasma etching. The metal layers 210 and 212 can be lines, islands, or pads composed of metals such as copper, aluminum, various metal compounds, or metal alloys. The metal layers 210 and 212 may be the same metal layer or different metal layers. The metal layers 210 and 212 may also have different sizes, and the heights of the metal layers 210 and 212 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com