Indium ¿C gallium ¿C arsenic line detectors with micro mesa-structure

A mesa structure, indium gallium arsenic technology, applied in the direction of semiconductor devices, sustainable manufacturing/processing, electrical components, etc., can solve the problems of affecting the detection rate of detectors, unfavorable device performance, increasing the surface recombination of photogenerated carriers, and achieving Improve long-term stability and reliability, and reduce the effect of contact surface states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in detail:

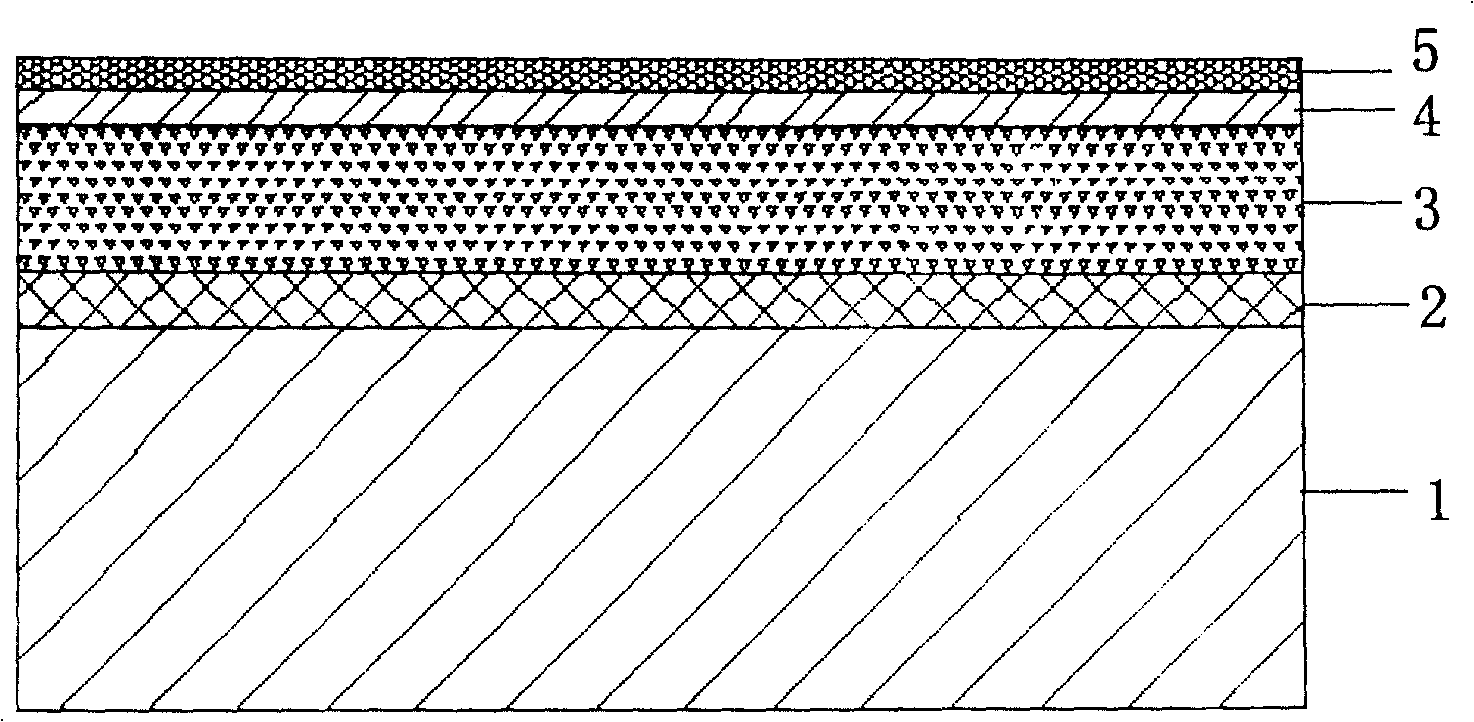

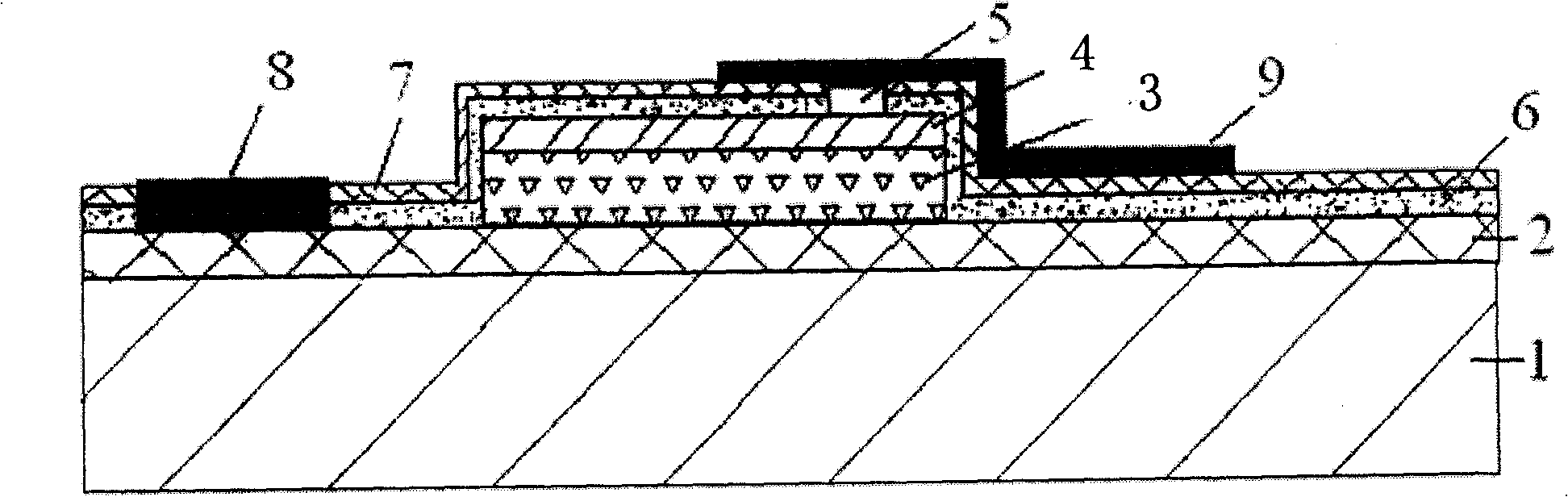

[0014] Such as figure 1 As shown, the epitaxial wafer includes: a semi-insulating InP substrate 1 with a thickness of 500 μm, which is sequentially arranged and grown on the semi-insulating InP substrate with a thickness of 1 μm and a carrier concentration of 2×10 18 cm -3 The n-type InP layer 2; the thickness is 2.5 μm, and the Si-doped concentration is 2×10 16 cm -3 In 0.53 Ga 0.47 As absorption layer 3; the thickness is 0.5 μm, and the carrier concentration is 2×10 18 cm -3 The P-type InP layer 4; the thickness is 20nm, and the carrier concentration is 2×10 18 cm -3 p-InGaAs layer 5.

[0015] The device preparation process is as follows:

[0016] 1. Ultrasonic cleaning the epitaxial wafer with chloroform, ether, acetone, and ethanol in sequence, each time for more than 2 minutes, and then blowing dry with nitrogen;

[0017] 2. Positive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com