Combined covering cap in use for columniform secondary battery of zinc-nickel

A secondary battery, cylindrical technology, applied to battery pack parts, circuits, electrical components, etc., can solve the problems of battery internal pressure rise, achieve the effect of preventing internal pressure rise, novel structure, and scientific composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

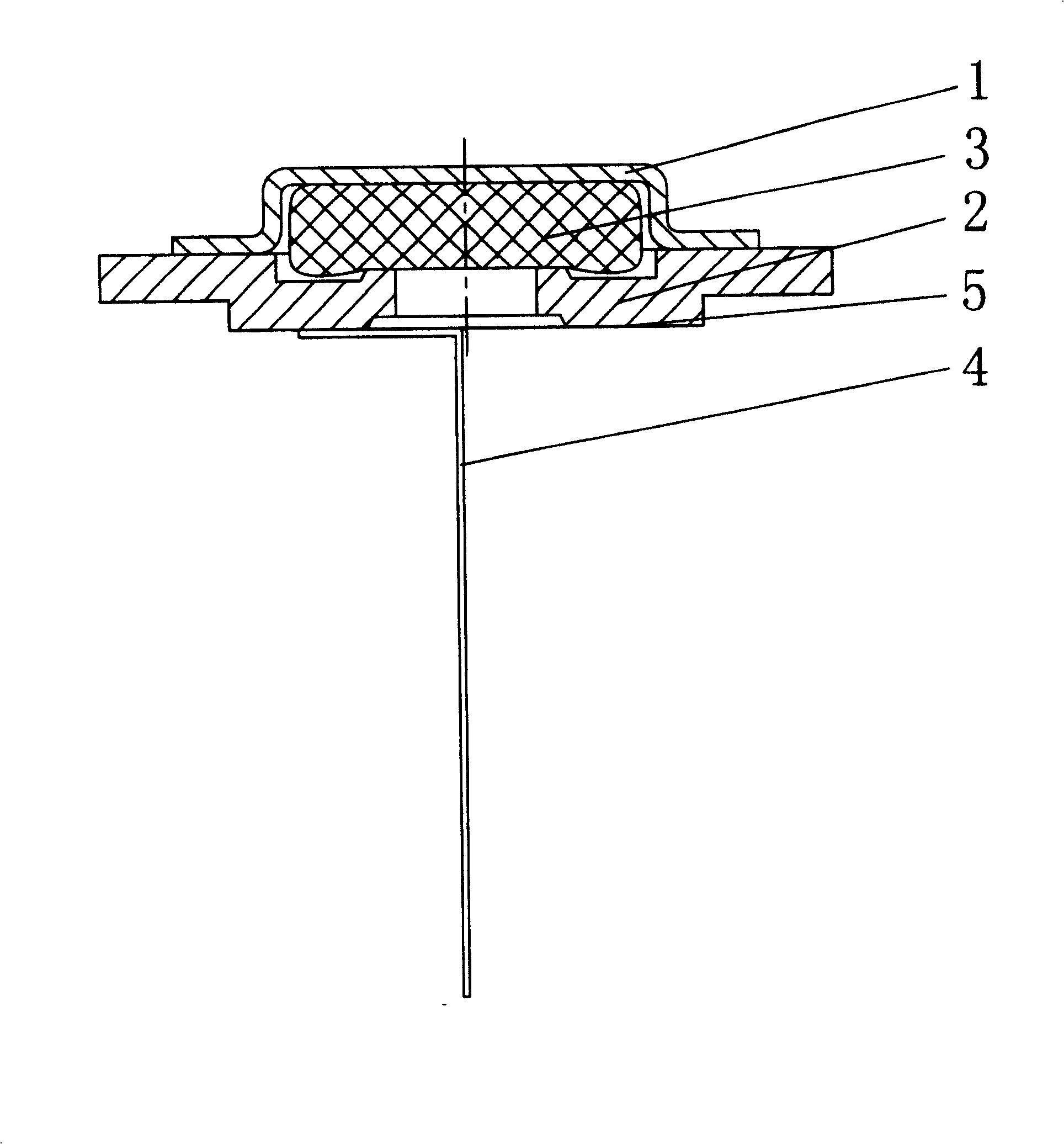

[0023] The first combination cap for 2 / 3AA cylindrical zinc-nickel secondary battery is composed of end cap 1, bottom cover 2 and explosion-proof parts 3 arranged between the end cap and the bottom cover, and the bottom cover 2 is welded with the zinc The current collector 4 of the negative electrode is connected by welding.

[0024] A lead-tin alloy layer 5 with a thickness of 5 microns and a high hydrogen evolution overpotential is electroplated and deposited on the surface of the bottom cover 2 .

[0025] The surface of the bottom cover 2 and the surface of the current collector 5 connected thereto are coated with an anti-corrosion paint layer, which is not shown in the drawings.

[0026] The anti-corrosion coating layer is a phenolic-acetal polymer bonding layer made of a JSF-2 phenolic-polyvinyl butyral adhesive.

specific Embodiment approach 2

[0027] The second combination cap for 2 / 3AA cylindrical zinc-nickel secondary battery has the same composition and structure as the first embodiment.

[0028] The anti-corrosion paint layer coated on the surface of the bottom cover 2 and the surface of the current collector 5 connected thereto is a phenolic-nitrile polymer bonding layer made of J-15 phenolic-nitrile rubber adhesive.

specific Embodiment approach 3

[0029] The third combination cap for 2 / 3AA cylindrical zinc-nickel secondary battery has the same composition and structure as the first embodiment.

[0030] The surface of the bottom cover 2 and the anti-corrosion paint layer coated on the surface of the current collector 5 connected to it are epoxy-nitrile polymer adhesives made of J-23 nitrile rubber modified epoxy adhesive. layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com