Method for preparing polyethylene ion chelating membrane by radiation graft method

A technology of radiation grafting and polyethylene, applied in the field of radiation grafting chemistry and chemical industry, can solve the problems of limiting the amount of functional groups introduced, the grafting rate is low, and the purity of PE-g-GMA grafts is low, and achieves excellent chelation. Combined adsorption performance, simple operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) at first preparation volume percentage is the GMA methanol solution of 5% as grafting liquid;

[0027] (2) Then the HDPE film is cleaned with acetone and dried to constant weight, and the weighed high-density polyethylene film is put into a polyethylene film bag, sealed and placed in an electron irradiation room for irradiation; The beam intensity is 5mA, and the total radiation dose is 150kGy;

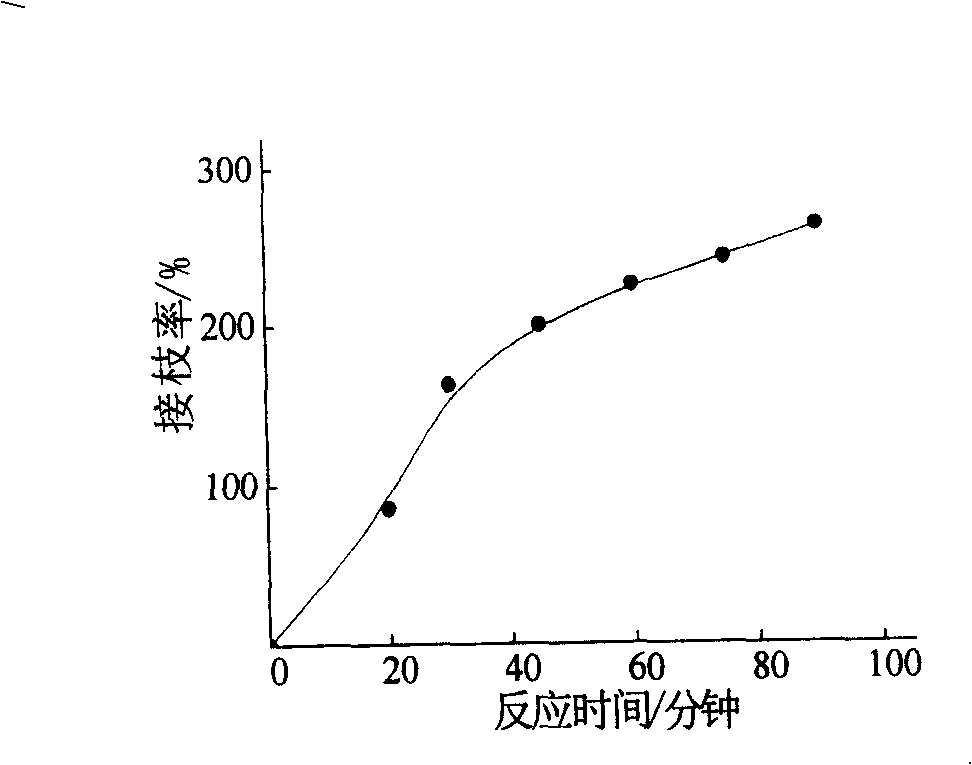

[0028] (3) In the third step, the irradiated HDPE film and the cushion material polypropylene non-woven fabric are stacked together, rolled up on a glass rod, tied up and placed in a graft tube containing a methanol solution of GMA, Vacuumize and fill with nitrogen to seal, then place the graft tube in a 50°C constant temperature water-soluble tank, react for 90 minutes, and obtain a graft film with a graft rate of 185%; take the graft film out of the graft tube, and use Washing with N,N-dimethylformamide, followed by immersion in a mixed solution of methanol and tetrahydr...

Embodiment 2

[0031] (1) at first preparation volume percentage is the GMA methanol solution of 20% as grafting liquid;

[0032] (2) Then the HDPE film is cleaned with acetone and dried to constant weight, and the weighed high-density polyethylene film is put into a polyethylene film bag, sealed and placed in an electron irradiation room for irradiation; The beam intensity is 5mA, and the total radiation dose is 150kGy;

[0033] (3) In the third step, the irradiated HDPE film and the cushion material polypropylene non-woven fabric are stacked together, rolled up on a glass rod, tied up and placed in a graft tube containing a methanol solution of GMA, Vacuumize and fill with nitrogen to seal, then place the graft tube in a 50°C constant-temperature water-soluble tank, react for 60 minutes, and obtain a graft film with a graft rate of 225%; take out the graft film from the graft tube, and use Washing with N,N-dimethylformamide, followed by immersion in a mixed solution of methanol and tetrah...

Embodiment 3

[0036] (1) at first preparation volume percentage is the GMA methanol solution of 30% as grafting liquid;

[0037] (2) Then the HDPE film is cleaned with acetone and dried to constant weight, and the weighed high-density polyethylene film is put into a polyethylene film bag, sealed and placed in an electron irradiation room for irradiation; The beam intensity is 5mA, and the total radiation dose is 150kGy;

[0038] (3) In the third step, the irradiated HDPE film and the cushion material polypropylene non-woven fabric are stacked together, rolled up on a glass rod, tied up and placed in a graft tube containing a methanol solution of GMA, Vacuumize and fill with nitrogen to seal, then place the graft tube in a 50°C constant temperature water-soluble tank, react for 15 minutes, and obtain a graft film with a graft rate of 73%; take the graft film out of the graft tube, and use Washing with N,N-dimethylformamide, followed by immersion in a mixed solution of methanol and tetrahydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com