Multiple quaternary ammonium salt anion exchange membrane and preparation method thereof

A technology of anion exchange membrane and multi-quaternary ammonium salt, which is applied in the direction of anion exchange, ion exchange, chemical instruments and methods, etc., can solve the problems of reducing the physical properties of the membrane, save the film forming process, easy to operate, and good thermal stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

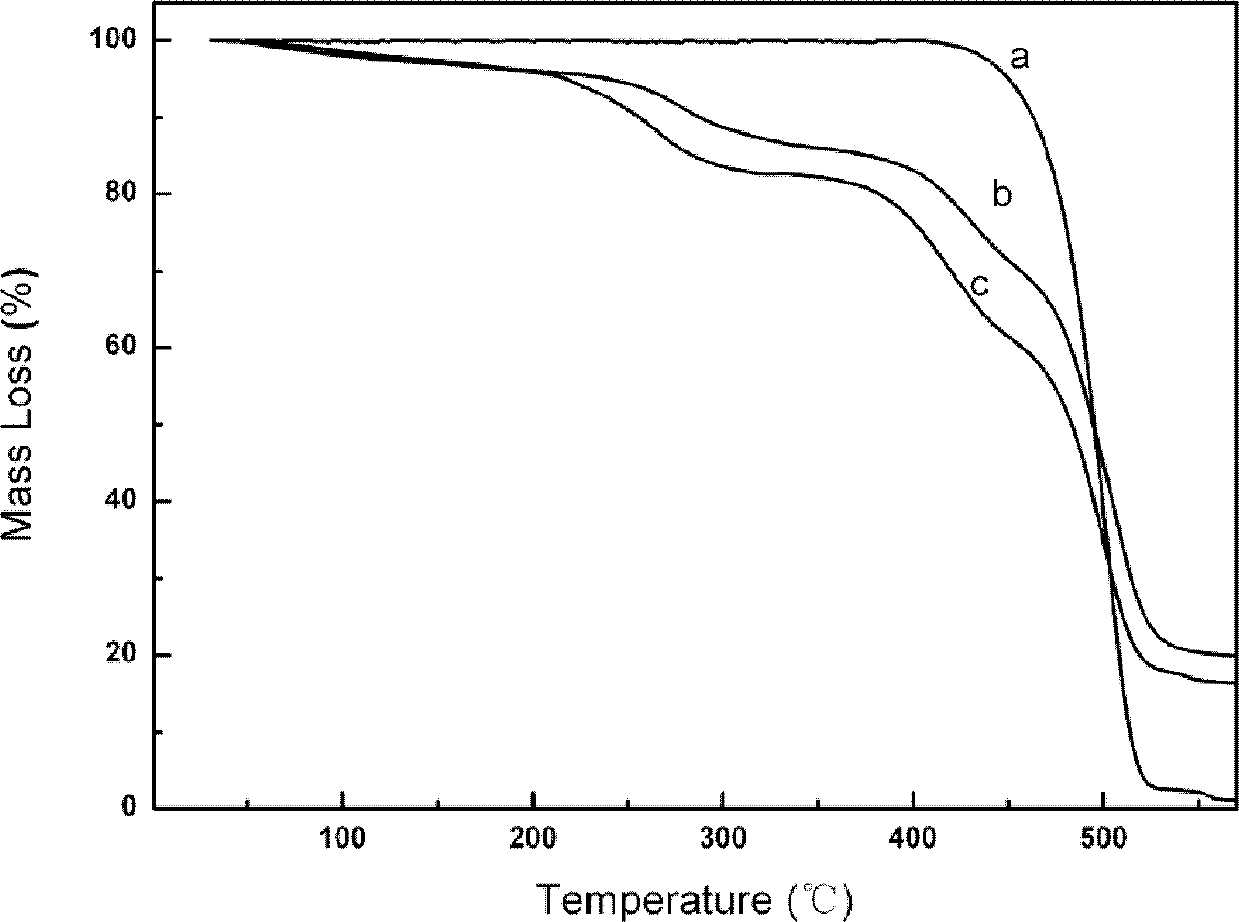

[0027] (1) Put the ethylene-tetrafluoroethylene copolymer film to remove impurities on the surface of the film and put it into 60 Co gamma ray radiation room irradiated, irradiated to a total dose of 90KGy.

[0028] (2) Submerge the irradiated film in a 60% toluene solution of chloromethylstyrene, pass argon to remove oxygen in the air, seal it, and react in a constant temperature water bath at 60° C. for 4 hours.

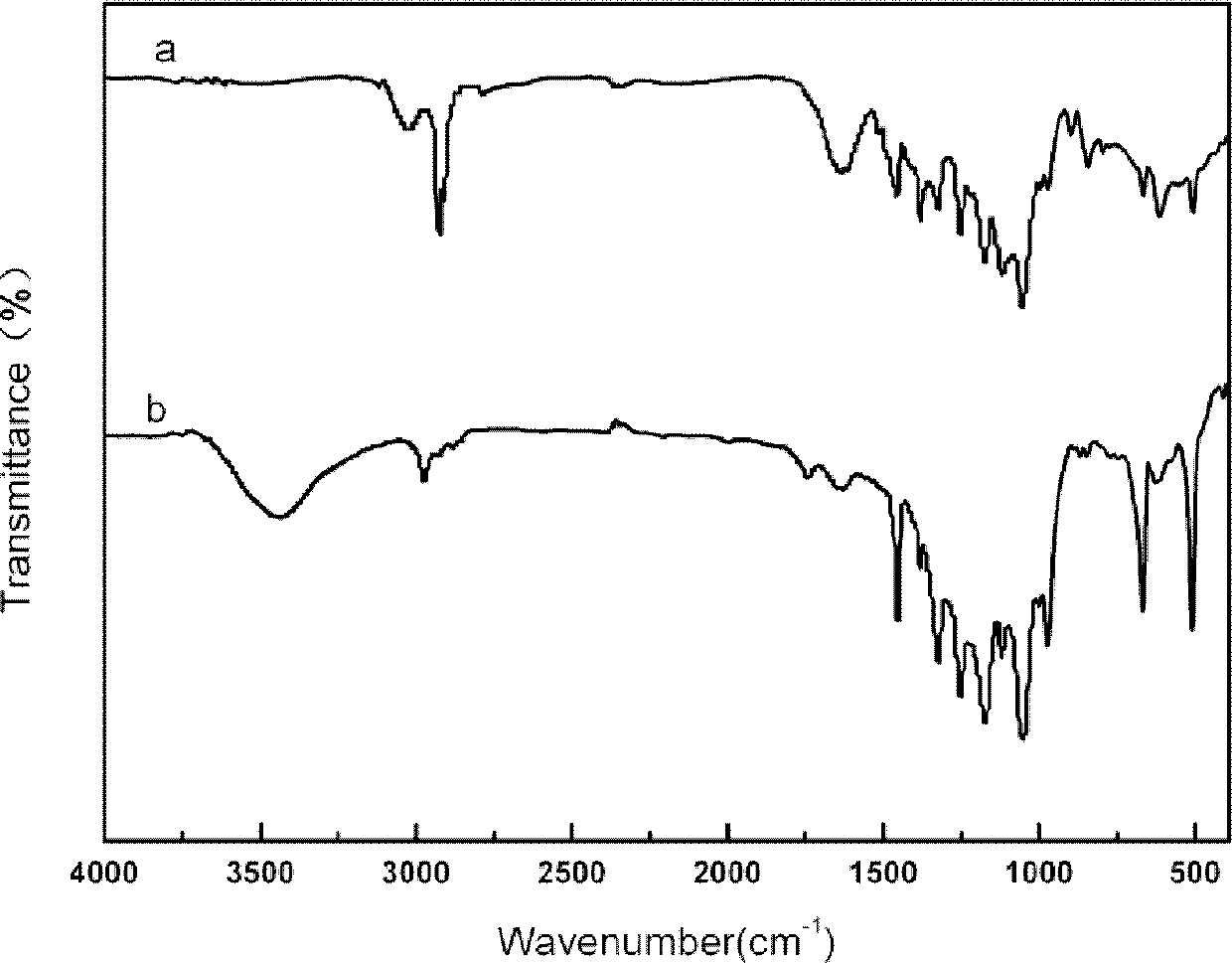

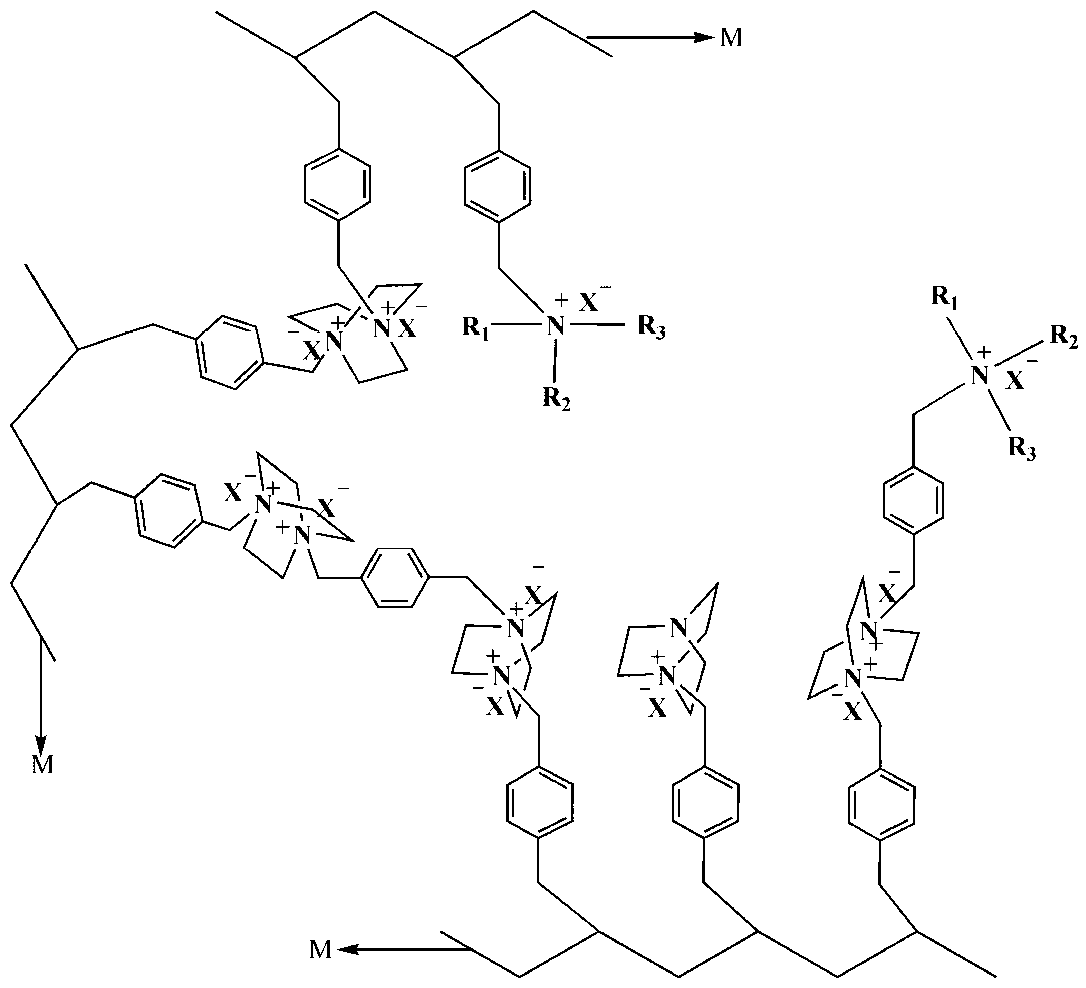

[0029] (3) Remove residual monomers and homopolymers in the film, immerse the film in a 2% triethylenediamine solution in toluene, and place it in a water bath at 70° C. for 16 hours.

[0030] (4) The membrane was cleaned, immersed in 2% bis(chloromethyl)benzene in toluene solution, and placed in a 70° C. water bath for 18 hours of reaction.

[0031] (5) The membrane was cleaned, immersed in 33% trimethylamine aqueous solution, and placed in a water bath at 60° C. for 24 hours. A chlorine-type polyquaternary ammonium salt-type anion exchange membrane is obtained....

Embodiment 2

[0036] (1) Put the tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer film to remove the impurities on the surface of the film and put it into a high-energy electron beam radiation chamber for irradiation to a total dose of 120KGy.

[0037] (2) Submerge the irradiated film in 80% dimethyl sulfoxide solution of iodomethylstyrene, pass through nitrogen to remove oxygen in the air, seal it, and react in a constant temperature water bath at 80° C. for 8 hours.

[0038] (3) Remove residual monomers and homopolymers in the film, immerse the film in a 4% tetrahydrofuran solution of triethylenediamine, and place it in a water bath at 70° C. for 16 hours.

[0039] (4) The membrane was cleaned, immersed in 4% bis(chloromethyl)benzene in toluene solution, and placed in a 70° C. water bath for 18 hours of reaction.

[0040] (5) The membrane was cleaned, immersed in 30% triethylamine aqueous solution, and placed in a 40° C. water bath for 36 hours to react to obtain a chlorine-type ...

Embodiment 3

[0043] (1) Remove the impurities on the surface of the polyvinylidene fluoride film and put it in 60 Irradiate in Co gamma ray radiation room, and irradiate to a total dose of 60KGy.

[0044] (2) Submerge the irradiated film in a 50% solution of bromomethylstyrene in tetrahydrofuran, pass argon to remove oxygen in the air, seal it, and react in a constant temperature water bath at 50° C. for 12 hours.

[0045] (3) Residual monomers and homopolymers in the film were removed, the film was immersed in 2% triethylenediamine in toluene solution, and placed in a 50° C. water bath for 17 hours of reaction.

[0046] (4) Clean the membrane, immerse it in a 2% bis(bromomethyl)benzene solution in toluene, and place it in a water bath at 50° C. for 18 hours.

[0047] (5) The membrane was cleaned, immersed in 30% triethylamine aqueous solution, and placed in a water bath at 30° C. for 12 hours. A chlorine-type multi-quaternary ammonium salt-type anion-exchange membrane and a multi-quater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com