Preparation method of proton exchange membrane for fuel batteries

A proton exchange membrane and fuel cell technology, which is applied to fuel cell components, fuel cells, battery pack components, etc., can solve the problems affecting the operational durability of the fuel cell system, poor chemical stability, etc. Strong, easy to operate, strong water retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] The specific process and steps in this embodiment are as follows:

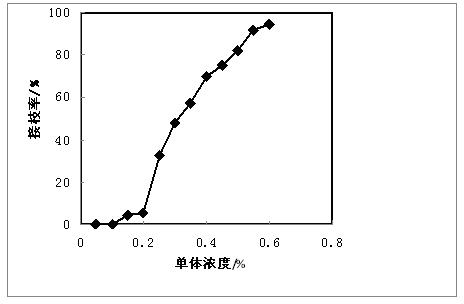

[0019] a. First prepare the grafting reaction reagent system, the composition and volume concentration of the reagents in the system are: methacrylic acid (MAA for short), 30% by volume, α-methylstyrene (AMS for short), 30% by volume %, the reaction solvent is toluene, and the volume percentage is 40%.

[0020] b. Degrease the cut ETFE film, dry and weigh it, put it into a polyethylene film bag, and fill the bag with high-purity nitrogen to drive away the air, seal it and place it in an electron irradiation room for irradiation The intensity of the electron beam is 1mA, and the total irradiation dose is 150kGy; in order to weaken the effect of irradiation temperature rise, intermittent irradiation is adopted. The ethylene-tetrafluoroethylene copolymer film (ETFE) in this example is purchased from outside.

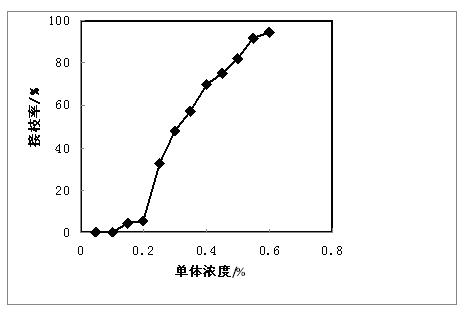

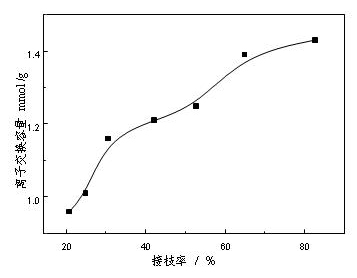

[0021] c. Add the mixed solution of AMS and MAA monomers and solvent toluene into the special g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com