Method for preparing polypropylene ion chelating membrane by radiation grafting method

A technology of radiation grafting and polypropylene membrane, which is applied in the field of ion chelation membrane preparation, can solve the problems of low purity of polypropylene grafts, limited introduction of functional groups, low grafting rate, etc., and achieve excellent chelation Adsorption properties, good mechanical properties, and large chelating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment one: the concrete steps of this embodiment are:

[0015] (1) at first preparation volume ratio is the N, N-dimethylformamide solution of the acrylonitrile of 20% as grafting reaction system;

[0016] (2) Then scrub the PP film with acetone and dry it to a constant weight. Put the weighed PP film into a polyethylene film bag, and fill the bag with high-purity nitrogen to drive away the air. After sealing, Place in an electron irradiation room for irradiation; the electron beam intensity is 1mA, and the total irradiation dose is 150kGy;

[0017] (3) In the third step, place the irradiated PP film in a graft tube filled with N,N-dimethylformamide solution of AN, vacuumize and fill with nitrogen to seal, and then place the graft tube at 50°C In a constant temperature water-soluble tank, react for 0.5 hours, take the grafted membrane out of the grafted tube, wash it with N, N-dimethylformamide, and then soak it for 12 hours to remove the homopolymer on the surfac...

Embodiment 2

[0019] Embodiment two: the concrete steps of this embodiment are:

[0020] (1) at first preparation volume ratio is the acrylonitrile N of 60%, N-dimethylformamide solution as grafting reaction system;

[0021] (2) Then scrub the PP film with acetone and dry it to a constant weight. Put the weighed PP film into a polyethylene film bag, and fill the bag with high-purity nitrogen to drive away the air. After sealing, Placed in an electron irradiation room for irradiation; the electron beam current intensity is 1mA, and the total irradiation dose is 300kGy;

[0022] (3) In the third step, place the irradiated PP film in a graft tube filled with N,N-dimethylformamide solution of AN, vacuumize and fill with nitrogen to seal, and then place the graft tube at 50°C In a constant temperature water-soluble tank, react for 2 hours, take the grafted membrane out of the grafted tube, wash it with N,N-dimethylformamide, and then soak it for 12 hours to remove the homopolymer on the surface...

Embodiment 3

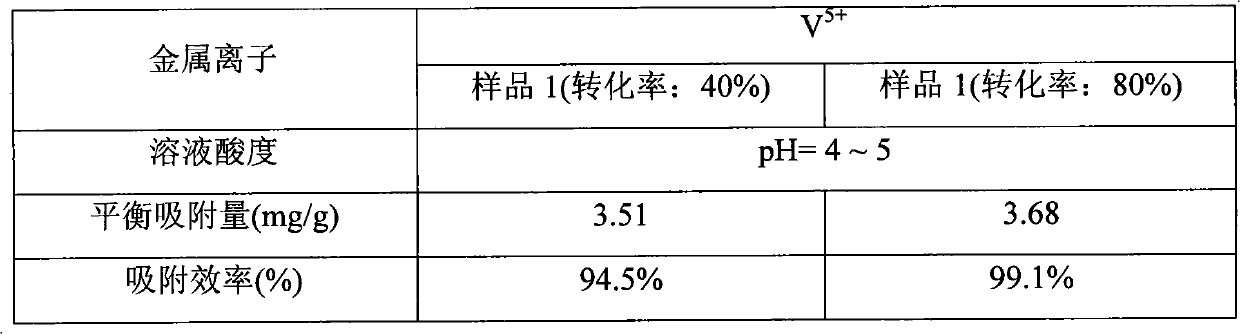

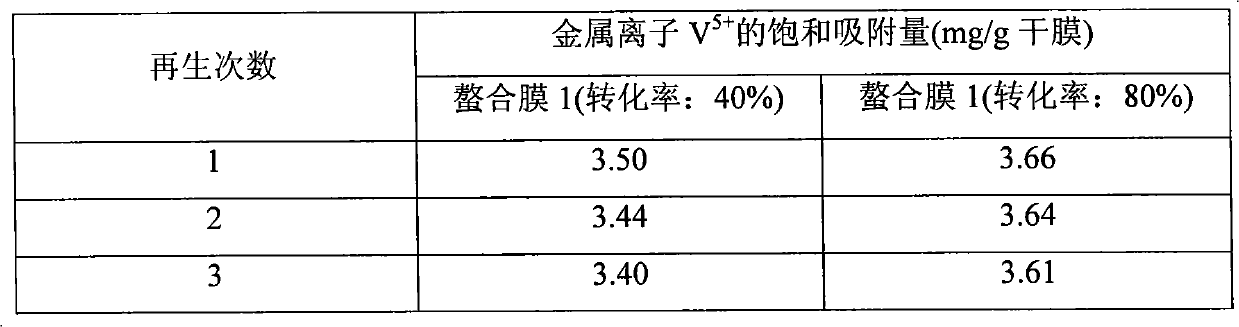

[0024] Embodiment three: adopt the chelating film sample 1 that above-mentioned embodiment makes and 2 to heavy metal ion V respectively 5+ Carry out chelation adsorption, and measure its equilibrium adsorption capacity and adsorption rate. The specific method is: take the chelating membrane, cut it into small pieces, weigh it accurately, put 0.1 grams in each equal portion into conical flasks, and then add V 5+ Metal ion solution (volume is 25mL), shakes 10 hours on the shaker, takes out chelating membrane, then measures the concentration of residual metal ion in the solution with inductively coupled plasma emission spectrometer, thereby calculates the chelating membrane that this invention makes The saturated adsorption capacity and adsorption efficiency of metal ions. The results are shown in Table 1.

[0025] Table 1 Equilibrium adsorption capacity and adsorption rate of metal ions by chelating membrane

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com