Neutral seasoning milk containing edible plant granules and its producing method

An edible plant and production method technology, applied in the field of flavored milk, can solve the problem that the taste, the flavor is single, the higher requirements of natural, green and nutrition cannot be satisfied, and the taste, flavor and nutrition are not greatly improved. and other issues, to achieve the effect of enriching nutritional value, strong market demand prospects, and satisfying taste requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

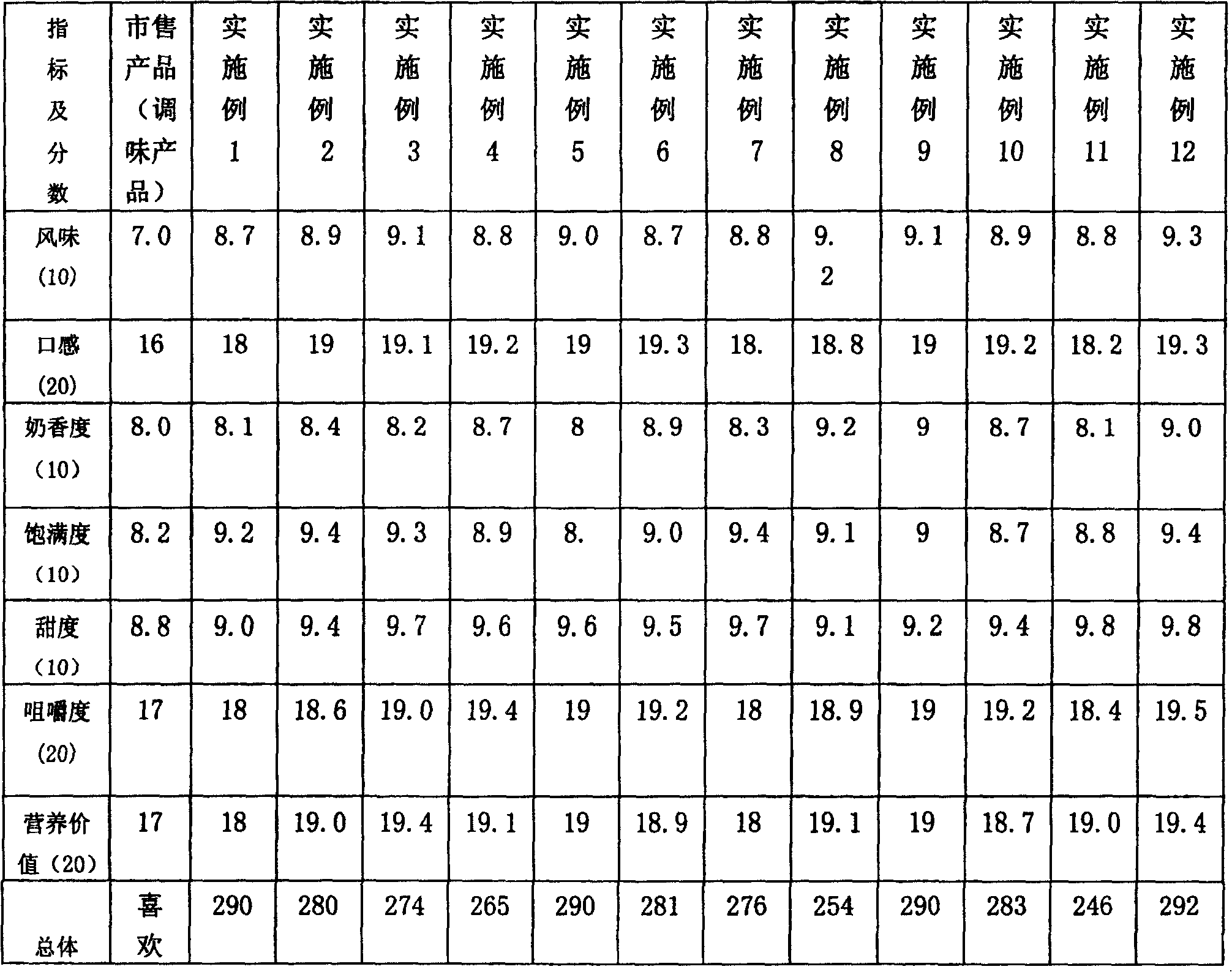

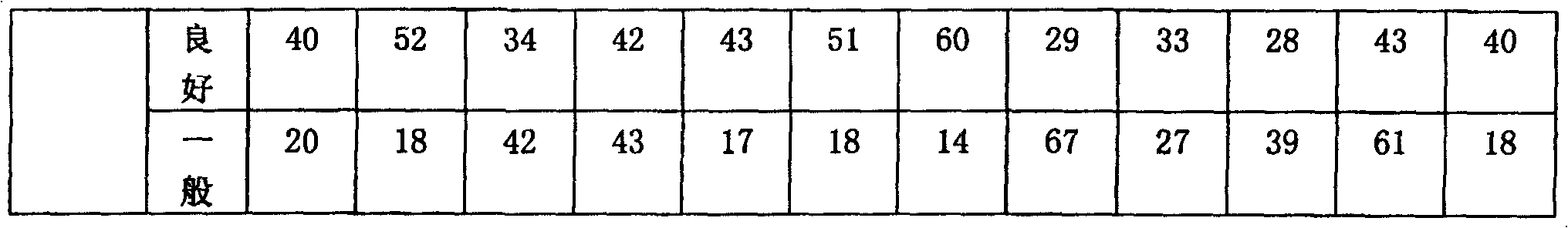

Examples

Embodiment 1

[0039] Embodiment 1, corn grain flavored milk

[0040] Raw material standard:

[0041] Milk: protein ≥ 2.95% fat ≥ 3.0% non-fat milk solids ≥ 8.5%

[0042] White granulated sugar: in line with the national first-class standard.

[0043] Corn kernels:

[0044] 1. The particles are fresh; full

[0045] 2. The length is 2-15mm, the width is 2-10mm

[0046] The preparation method of flavored milk of the present invention comprises the following steps:

[0047] 1) Take the material according to the following raw material formula (based on 1 ton):

[0048] 900.0 kg of milk, 70.0 kg of white sugar, 0.8 kg of glyceryl monostearate,

[0049] Diacetyl tartrate monoglyceride 0.4 kg, gelatin 0.3 kg, carrageenan 0.2 kg,

[0050] 0.1 kg of gum arabic, 0.2 kg of pectin, 27 kg of corn grains,

[0051] 0.7 kg of corn essence and 0.3 kg of milk essence.

[0052] 2) Ingredients: Pour 4°C cold milk into the batching tank; put an appropriate amount of milk (500 kg, the ratio of the amount...

Embodiment 2

[0064] Embodiment 2, aloe vera granule flavored milk

[0065] Milk: protein ≥ 2.95% fat ≥ 3.0% non-fat milk solids ≥ 8.5%

[0066] White granulated sugar: in line with the national first-class standard.

[0067] Aloe pulp: pulp content ≥ 60.0%;

[0068] 1. The pulp is fresh;

[0069] 2. The length of the pulp is 2-10mm, and the width is 2-10mm

[0070] The preparation method of flavored milk of the present invention comprises the following steps:

[0071] 1) Take the material according to the following raw material formula (based on 1 ton):

[0072] 880.0 kg of milk, 65.0 kg of white sugar, 1.0 kg of glyceryl monostearate,

[0073] Diacetyl tartrate monoglyceride 0.4 kg, guar gum 0.3 kg, carrageenan 0.2 kg,

[0074] 0.3 kg of gelatin, 53.0 kg of diced aloe gel, 0.8 kg of aloe essence;

[0075] 2) Ingredients: Pour 6°C cold milk into the batching tank; put an appropriate amount of milk (400 kg, the ratio of the amount of milk to the mixture of emulsifier and thickener is...

Embodiment 3

[0086] Embodiment 3, peanut flavored milk

[0087] Raw material standard:

[0088] Milk: protein ≥ 2.95% fat ≥ 3.0% non-fat milk solids ≥ 8.5%

[0089] White granulated sugar: in line with the national first-class standard.

[0090] Peanut granules (whole peanuts and half peanuts can be added, and half peanuts are added in this implementation)

[0091] 1) Cut the whole peanut in half along the midline to obtain half peanuts

[0092] 2) The grains are fresh; plump, the length of half grain is 10-20mm, and the width is 6-12mm

[0093] 3) The moisture content of half a peanut is controlled below 20%.

[0094] 4) Half peanut protein ≥ 25% fat ≥ 40%

[0095] making process:

[0096] 1) Take the material according to the following raw material formula (based on 1 ton):

[0097] 900.0 kg of milk, 70.0 kg of white sugar, 0.8 kg of glyceryl monostearate,

[0098] Sodium caseinate 0.2 kg, diacetyl tartrate monoglyceride 0.4 kg, guar gum 0.2 kg,

[0099] 0.25 kg of gelatin, 0.15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com