Liquid crystal aligning agent for photoalignment and liquid crystal display device utilizing the same

A technology of liquid crystal alignment agent and optical alignment, which is applied in liquid crystal materials, optics, nonlinear optics, etc. It can solve the problems that the electrical characteristics do not propose the structure of the liquid crystal alignment film, and the selection of alignment film materials is not too many, so as to achieve good voltage retention characteristics. , It is not easy to display unevenness, and the effect of accumulating less charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0078] Explanation of abbreviations used in this example

[0079] (tetracarboxylic dianhydride)

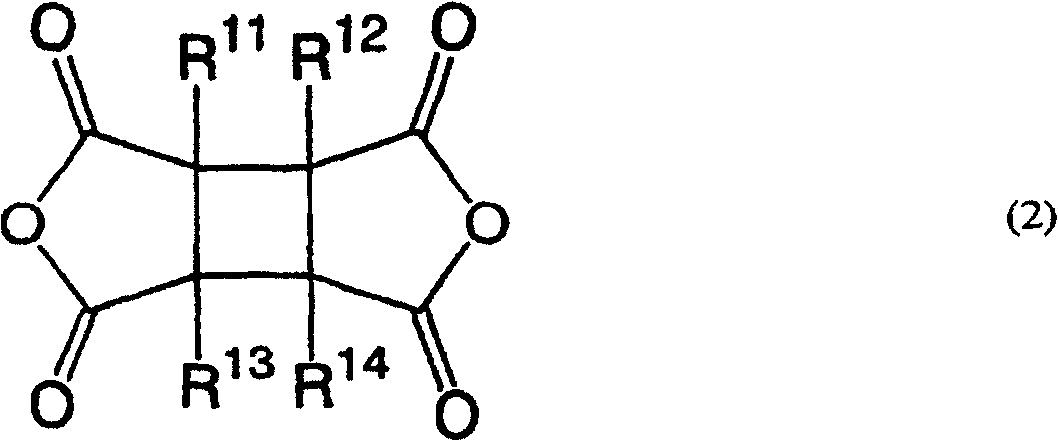

[0080] CBDA: 1,2,3,4-cyclobutanetetracarboxylic dianhydride

[0081] 1,3DM-CBDA: 1,3-dimethyl-1,2,3,4-cyclobutanetetracarboxylic dianhydride (diamine)

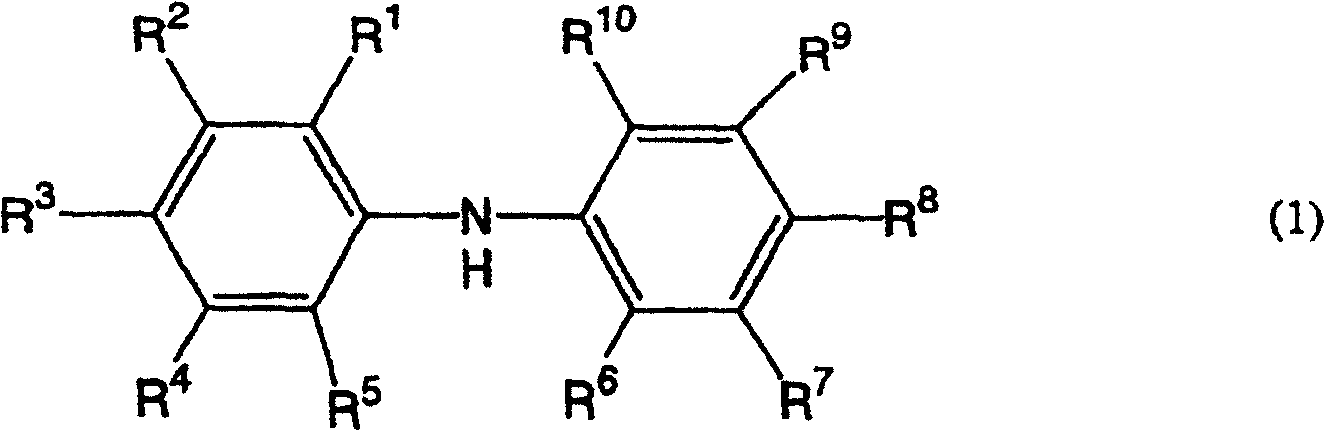

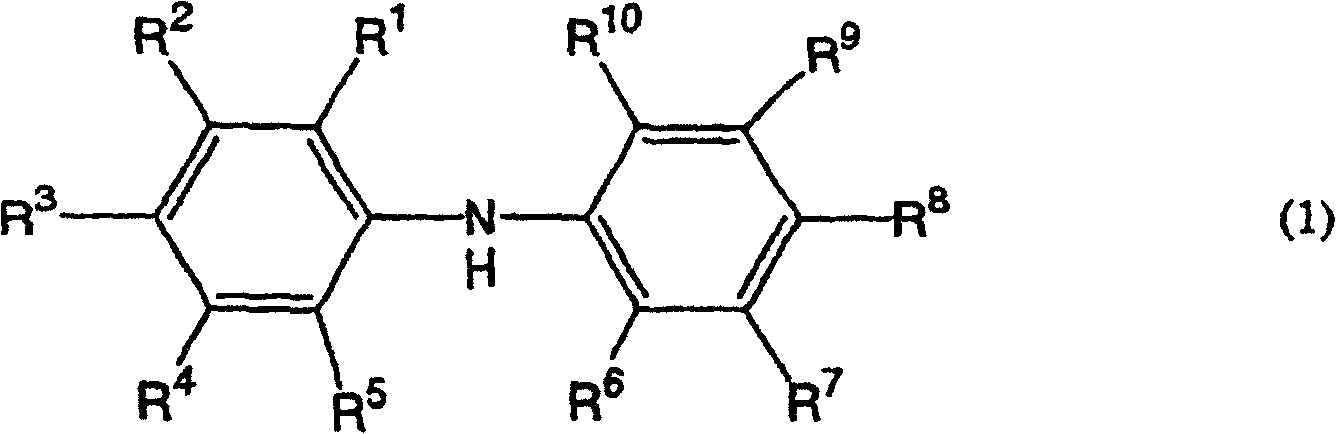

[0082] 4,4'DADPA: 4,4'-Diaminodiphenylamine

[0083] p-PDA: p-phenylenediamine

[0084] DDE: 4,4'-diaminodiphenyl ether

[0085] (Organic solvents)

[0086] NMP: N-methyl-2-pyrrolidone

[0087] BCS: Butyl Cellosolve

Synthetic example 1

[0088] (Synthesis Example 1) CBDA / 4,4'DADPA

[0089] Mix 19.61 g (0.1 mol) of CBDA as a tetracarboxylic dianhydride component and 19.13 g (0.096 mol) of 4,4'DADPA as a diamine component in 348.6 g of NMP, and react at room temperature for 5 hours to obtain a polyamide acid solution A. The polymerization reaction proceeded easily and uniformly, and when the weight average molecular weight of the obtained polyamic acid was measured with GPC-101 (manufactured by Shodex), it was 50000 (in terms of polyethylene glycol and polyethylene oxide). Further, NMP and BCS were added to make the solution 4% by weight of polyamic acid, 76% by weight of NMP, and 20% by weight of BCS, thereby obtaining the liquid crystal aligning agent of the present invention.

Synthetic example 2

[0090] (Synthesis Example 2) CBDA / 4,4'DADPA, CBDA / p-PDA

[0091] Mix 19.61g (0.1mol) of CBDA as a tetracarboxylic dianhydride component and 10.38g (0.096mol) of p-PDA as a diamine component in 269.9g of NMP, and react at room temperature for 5 hours to obtain a polyamic acid solution b. The polymerization reaction proceeded easily and uniformly, and it was 47,000 when the weight average molecular weight of the obtained polyamic acid was measured in the same manner as in Synthesis Example 1. The polyamic acid solution A and polyamic acid solution B obtained in Synthesis Example 1 were mixed at a solid content ratio of 1:1 to obtain a uniform solution. Further, NMP and BCS were added to make the solution 4% by weight of polyamic acid, 76% by weight of NMP, and 20% by weight of BCS, thereby obtaining the liquid crystal aligning agent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com