Medium and high temperature sealing method of plate type solid oxide fuel battery and its sealing material

A solid oxide, fuel cell technology, applied in solid electrolyte fuel cells, fuel cell components, chemical instruments and methods, etc., can solve the problems of concentration, deformation stress, complex sealing technology in the preparation process of sealant, etc. Simple process, good sealing performance, thermal matching performance and excellent chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

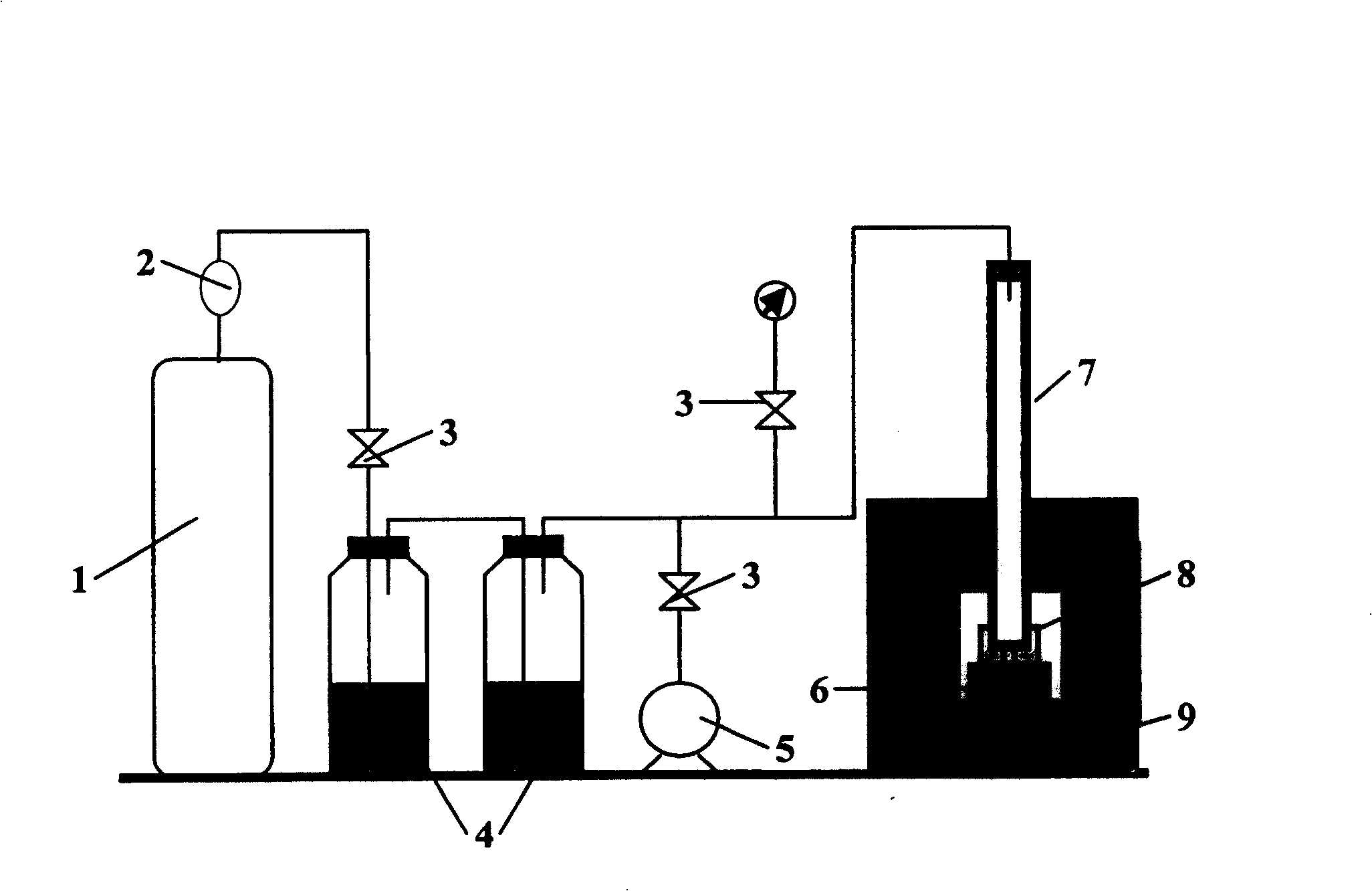

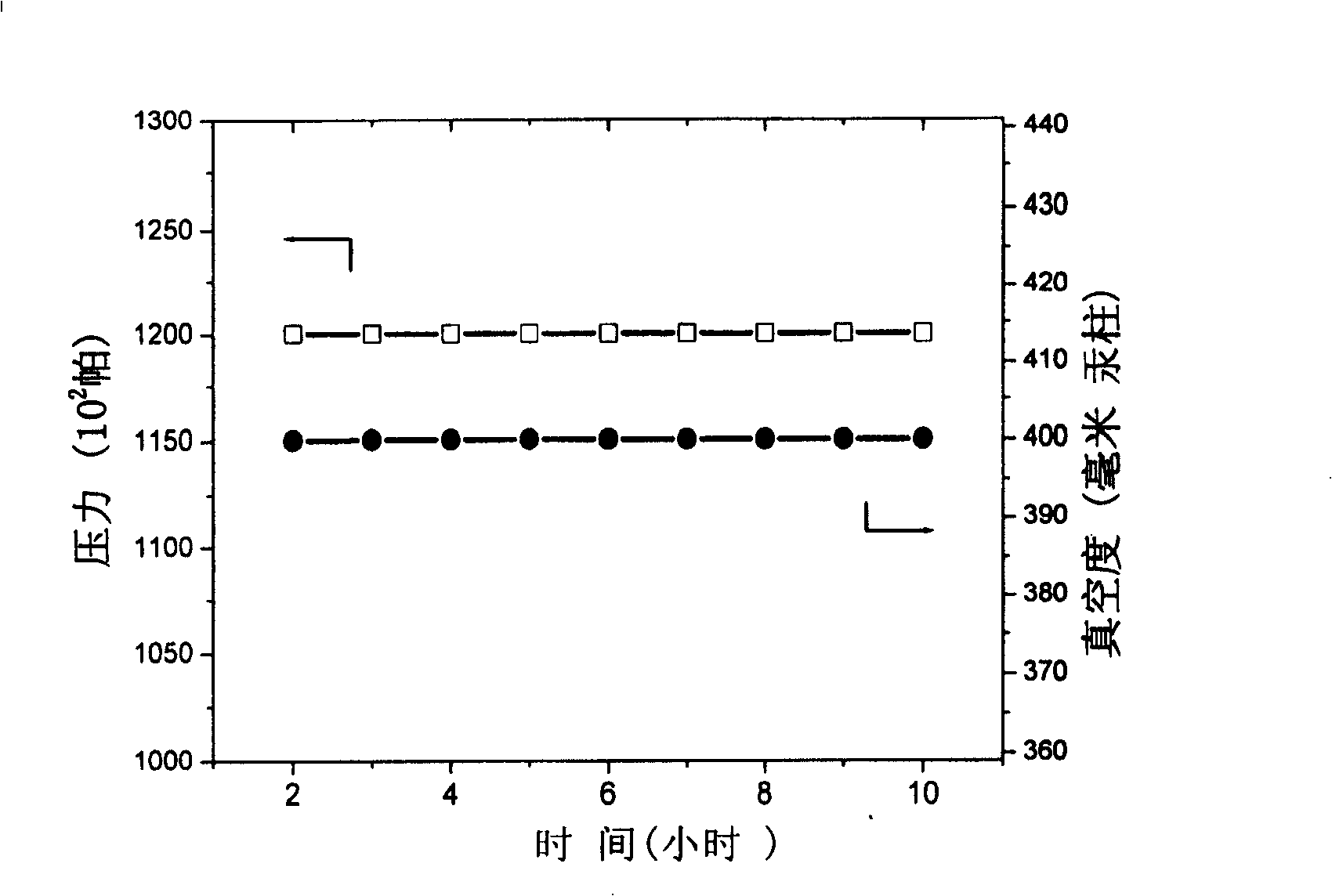

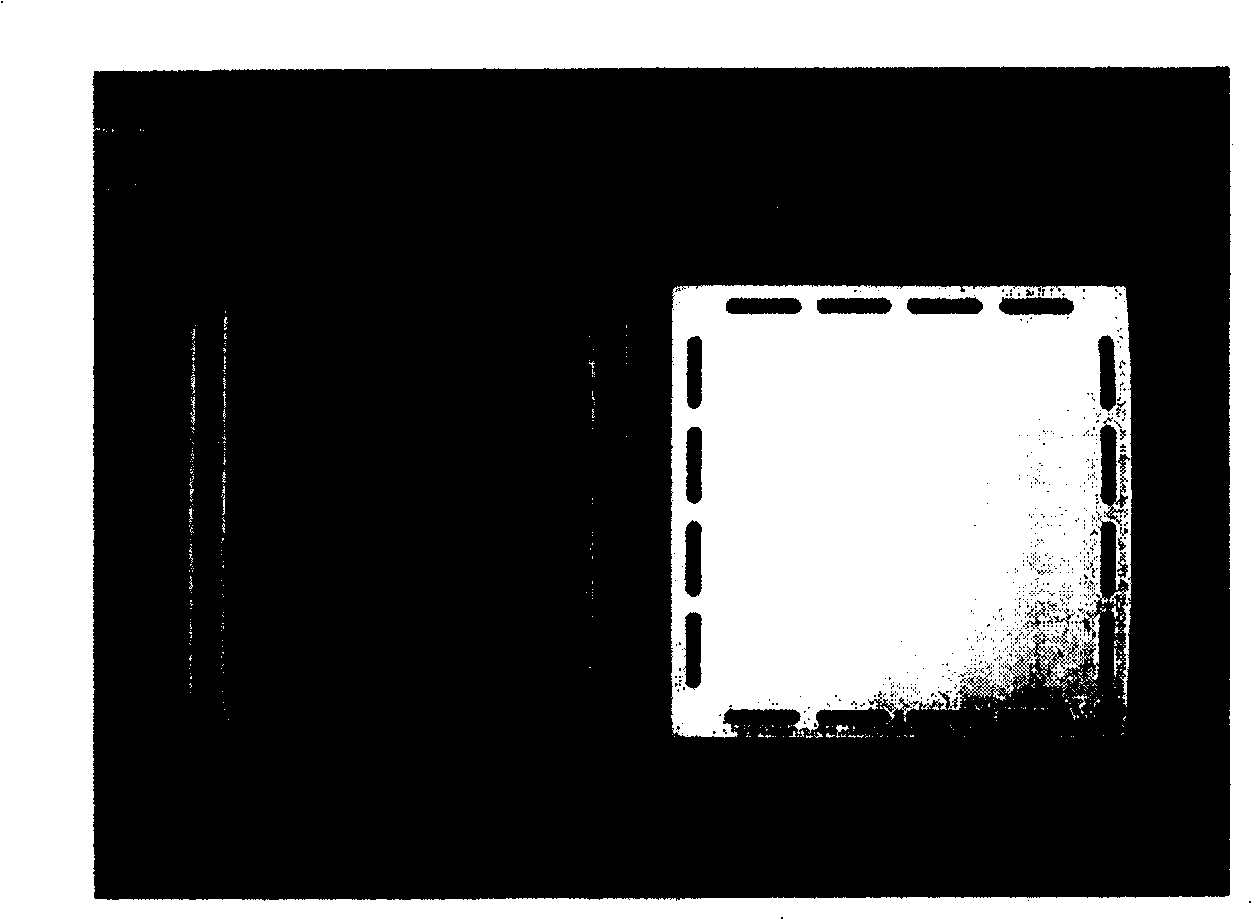

[0024] specific implementation plan

[0025] Further illustrate substantive characteristics and remarkable progress of the present invention below in conjunction with specific example:

[0026] ①Preparation of sealing material

[0027] Take 15.0 grams of CaO, Al 2 o 3 5.6 g, SiO 2 60.6 grams, B 2 o 3 2.5g, ZnO5.8g, BaO3.7g, Na 2 O 3.3 g, K 2 O3.4 grams, mixed with 500 grams of zirconia balls, put into a 1000ml polytetrafluoroethylene ball mill jar, and mixed with a drum mill for 2 hours. Put the 100ml sintered quartz crucible into the electric furnace and raise the temperature to 1300°C. Put the powder into the crucible at 1300°C, then raise the temperature at 3°C / min to 1400°C for 2 hours, and stir once every 0.5 hours during the heat preservation period. After the melting is completed, cast the molten body on a hot iron plate at 150°C to 200°C to form a disc. After forming, put it into an electric furnace at 500°C for annealing for 10 hours, and then cool with the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com