Spring-elastic measuring element comprising a flat connecting element that can be welded

A technology for measuring components and connecting components, which is applied in the measurement of fluid pressure through mechanical components, fluid pressure measurement of elastic deformation gauge, welding/welding/cutting items, etc., and can solve the problem of not being able to be replaced immediately, the strength of spring-type elastic measuring components and Adverse effects of corrosion resistance, welding work hindrance, etc., achieve high welding speed, improve mechanical and technical characteristics, and suppress the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

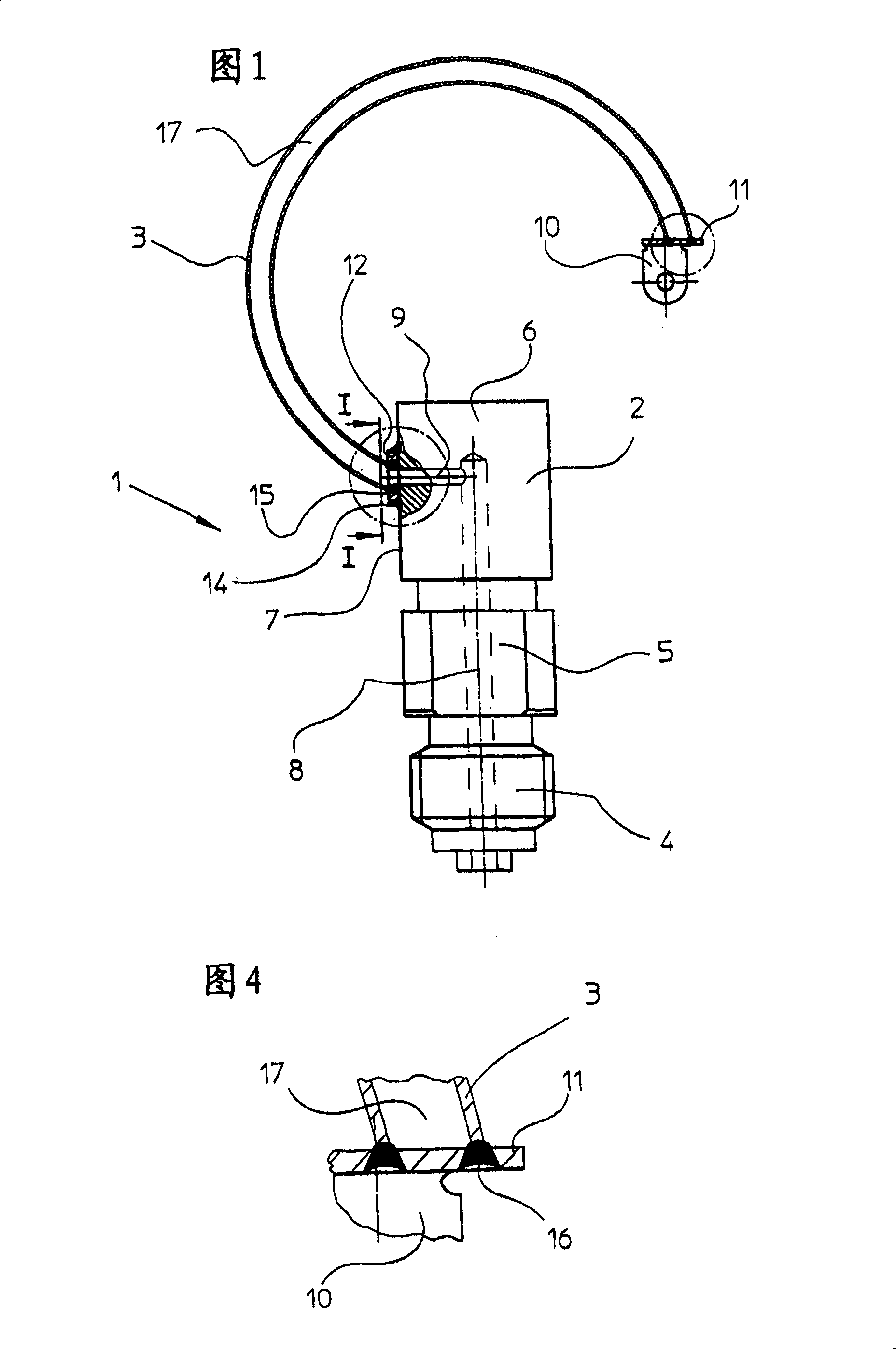

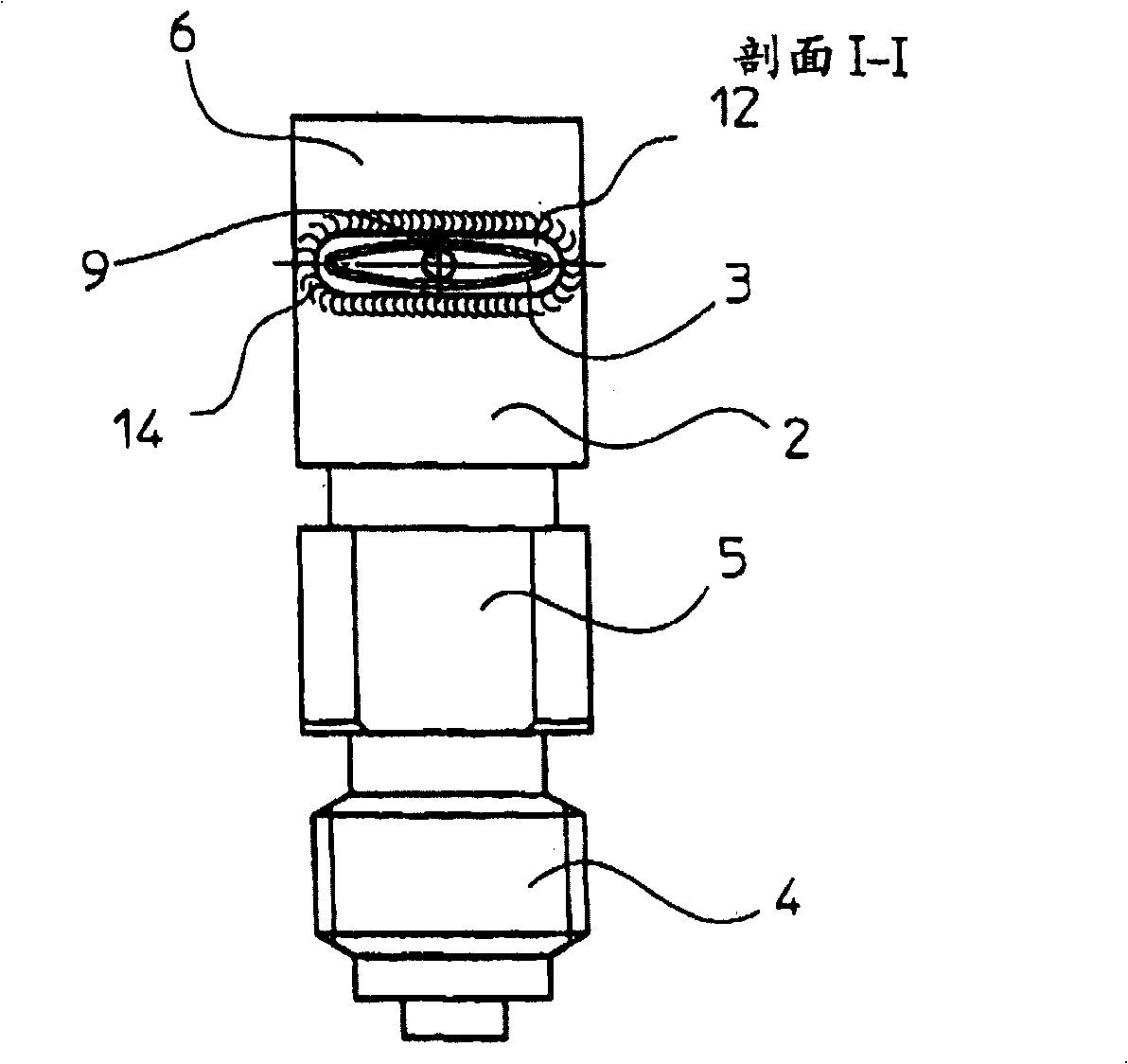

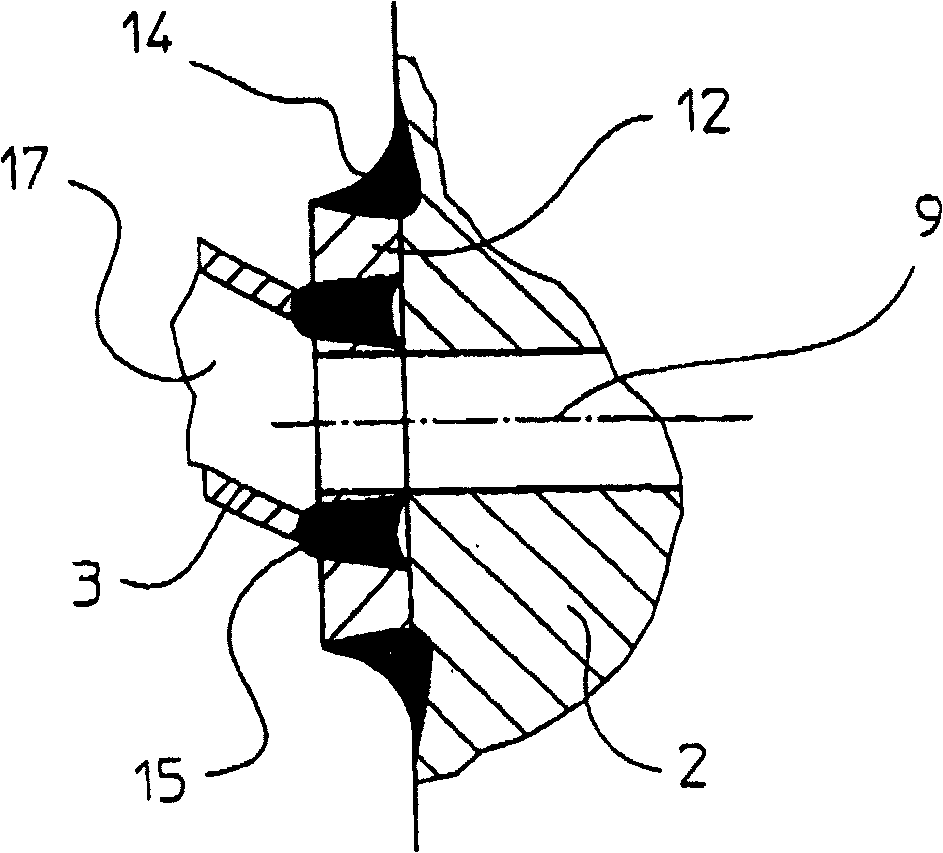

[0018] FIG. 1 shows a spring-loaded elastic measuring element 1 according to the invention, which consists of a base body 2 , a measuring tube 3 and a measuring device, not shown. The base body 2 is formed from a cuboid, which includes a screw connection 4 formed on one side, a middle part 5 and a top part 6 , which has at least one flat surface 7 . In the illustrated embodiment, the base body is of square cross-section. A longitudinal bore 8 is provided in the axial direction of the base body 2 , protruding straight into the top part 6 , which opens into the plane 7 via a transverse bore 9 .

[0019] The measuring tube 3 is arc-shaped and connected to the base body 2 at one end and to a connecting arm 10 at the other end. A first connecting element 11 is arranged between the connecting arm 10 and the measuring tube 3 , and a second connecting element 12 is arranged between the base body 2 and the measuring tube 3 , the connecting elements 11 , 12 have almost the same walls a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com