Method for separating sec-butyl acetate, acetic acid and heavy hydrocarbon

A technology of sec-butyl acetate and acetic acid, applied in the field of separating sec-butyl acetate, acetic acid and heavy hydrocarbons, can solve the problems such as methods for impurities such as acetic acid, sec-butyl acetate and heavy hydrocarbons that are not mentioned or proposed, and achieves The effect of reducing energy and material consumption, alleviating easy scaling, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

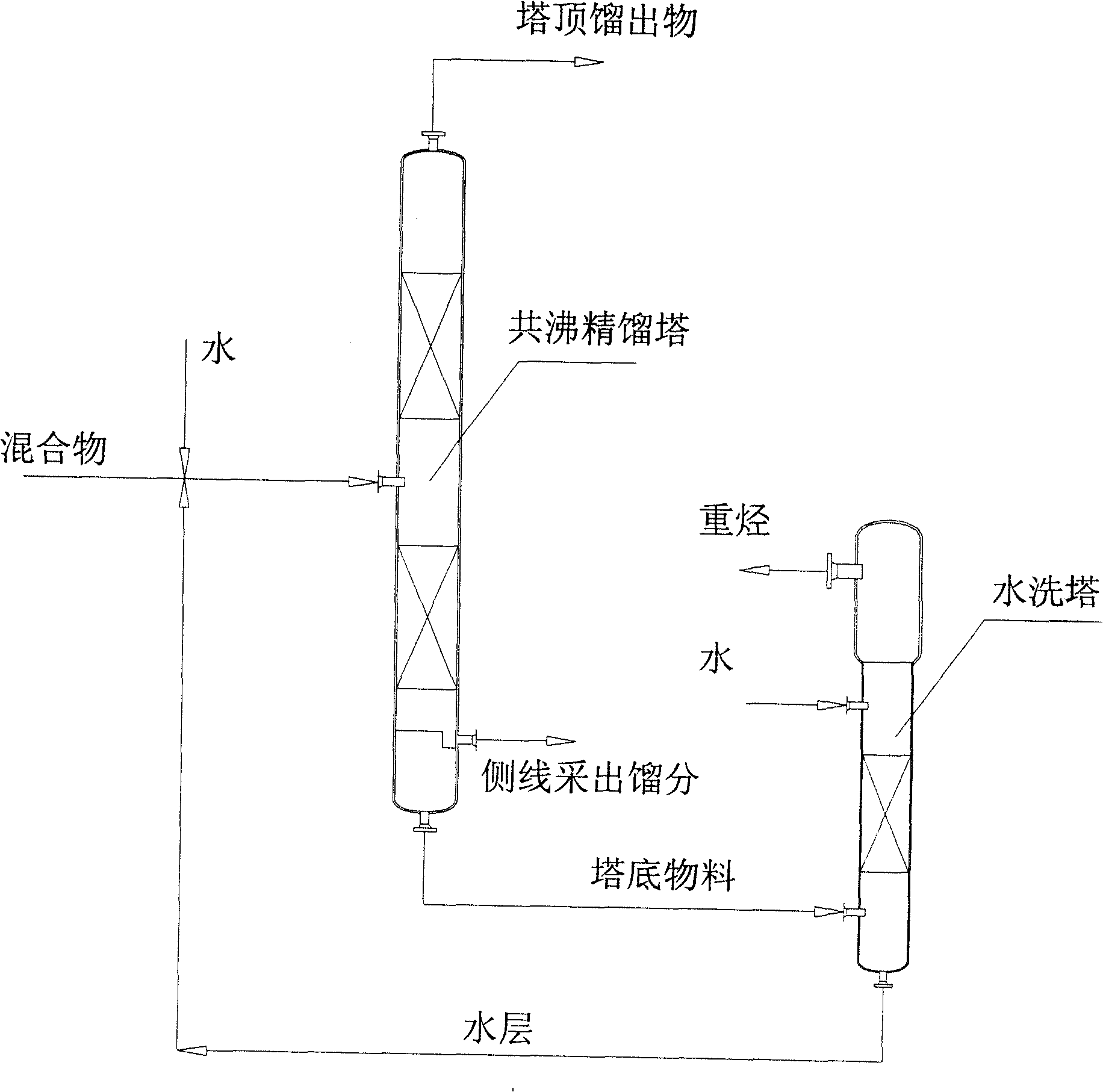

[0021] Such as figure 1 As shown, the mass composition is 52.28% of sec-butyl acetate, 43.22% of acetic acid, hydrocarbons and other substances. Add the entrainer water to the azeotropic rectification column in the proportion. The temperature at the bottom of the azeotropic distillation tower is 120°C, and the temperature at the top of the tower is 85.5°C. The mass composition of the overhead distillate obtained after the azeotropic distillation is: 94.613% of sec-butyl acetate, 0.007% of acetic acid, and 0.98% of water , hydrocarbons and other substances 4.4%. This overhead can be further refined.

[0022] The mass composition of the side-drawing fraction at the lower part of the azeotropic distillation tower is: 7.28% of sec-butyl acetate, 89.3% of acetic acid, 0.42% of water, 3% of hydrocarbons and other substances, and the side-drawing fraction is recycled to the reaction system.

[0023] The bottom material of the azeotropic rectification tower enters the lower part of...

Embodiment 2

[0027]The mass composition is that the mixture of sec-butyl acetate 56.26%, acetic acid 40.24%, hydrocarbons and other substances 3.5% is added to the azeotropic rectification column, and simultaneously by sec-butyl acetate: water=4: 1 (mass percentage) ratio to Add entrainer water in the azeotropic rectification tower. The temperature at the bottom of the azeotropic distillation column is 105°C, and the temperature at the top of the column is 78.1°C. The mass composition of the overhead distillate obtained after azeotropic distillation is: 95.99% of sec-butyl acetate, 0.01% of acetic acid, 0.9% of water, 3.1% of hydrocarbons and other substances. This overhead can be further refined.

[0028] The mass composition of the fraction drawn from the side stream at the lower part of the azeotropic distillation tower is: 8.32% of sec-butyl acetate, 88.17% of acetic acid, 0.51% of water, and 3% of hydrocarbons and other substances. The side draw fraction is recycled back to the reac...

Embodiment 3

[0031] The mass composition is that the mixture of sec-butyl acetate 52.79%, acetic acid 42.71%, hydrocarbons and other substances 4.5% is added to the azeotropic rectification column, and simultaneously by sec-butyl acetate: water=4: 1 (mass percentage) ratio to Add entrainer water in the azeotropic rectification tower. The temperature at the bottom of the azeotropic distillation tower is 128°C, and the temperature at the top of the tower is 86.5°C. The mass composition of the overhead distillate obtained after the azeotropic distillation is: 95.94% of sec-butyl acetate, 0.01% of acetic acid, and 1% of water , hydrocarbons and other substances 3.05%. This overhead can be further refined.

[0032] The mass composition of the fraction drawn from the side stream at the lower part of the azeotropic distillation tower is: 13.68% of sec-butyl acetate, 77.61% of acetic acid, 4.5% of water, and 4.21% of hydrocarbons and other substances. The side draw fraction is recycled back to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com