Method for producing zeolite molecular sieve film carrier noble metal catalyst

A zeolite molecular sieve membrane, precious metal catalyst technology, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as application limitations, small specific surface area of precious metal catalysts, etc., to achieve convenient operation, good catalytic activity, The effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] Step 1, immerse the stainless steel sheet (25×60mm) in hydrochloric acid with a mass concentration of 25% for surface treatment, and soak for 4 hours. Take out the stainless steel sheet, wash it with deionized water until the surface is clean and free of acid residue, and dry it at 25°C for later use.

[0022] Step 2, the tetraethyl orthosilicate (TEOS) of 38.4g (chemically pure, manufacturer is Tianjin Chemical Reagent No. The manufacturer is Tianjin Dengfeng Chemical Reagent Factory), 20g of deionized water and 1.5g of nitric acid (65% mass fraction) are added in the there-necked flask to form a mixed solution, and the molar ratio of the mixed solution is: TEOS to ethanol to distilled water ratio Nitric acid=1:3.8:6.4:0.08. The three-necked flask was placed in a water bath at 60° C. and stirred at a stirring speed of 120 r / min for 2 hours. The prepared adhesive is placed under the condition of 25° C. for use.

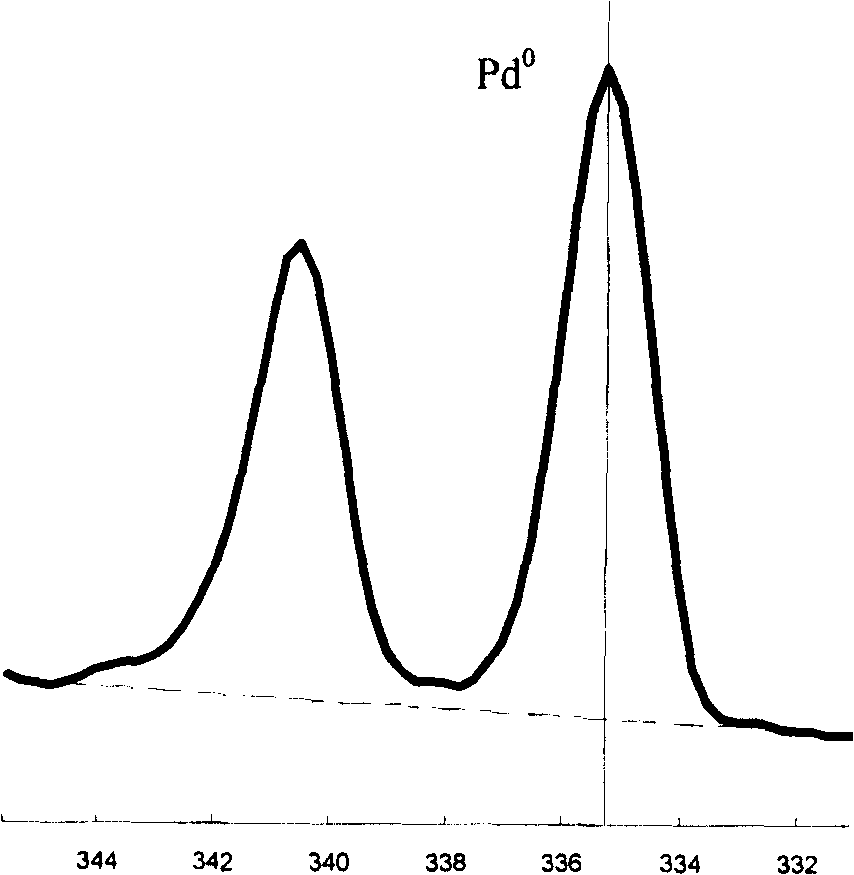

[0023] Step 3, with HZSM-5 molecular sieve (purchase f...

example 2

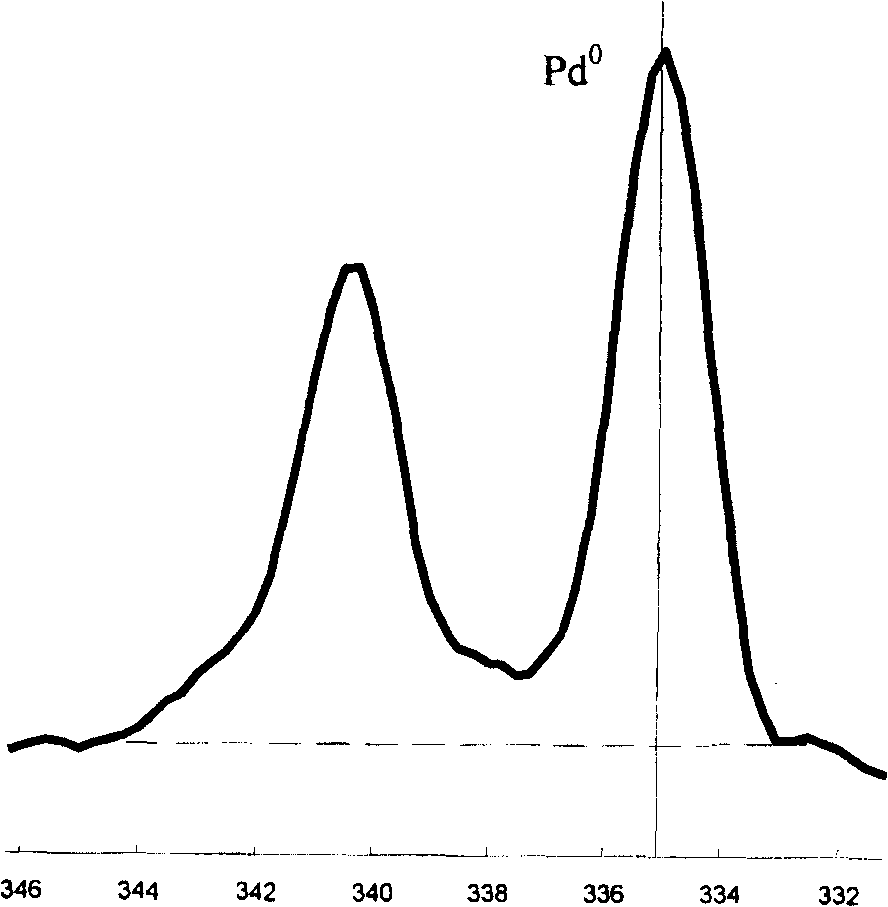

[0030] Step is the same as example 1, utilizes NH 4 OH (25%-28% mass fraction) to adjust the pH of the plating solution in step 5 to 10. The composition of the coating and the valence state of Pd were analyzed by XPS, and the atomic content of Pd on the surface of the catalyst was found to be 0.6%.

example 3

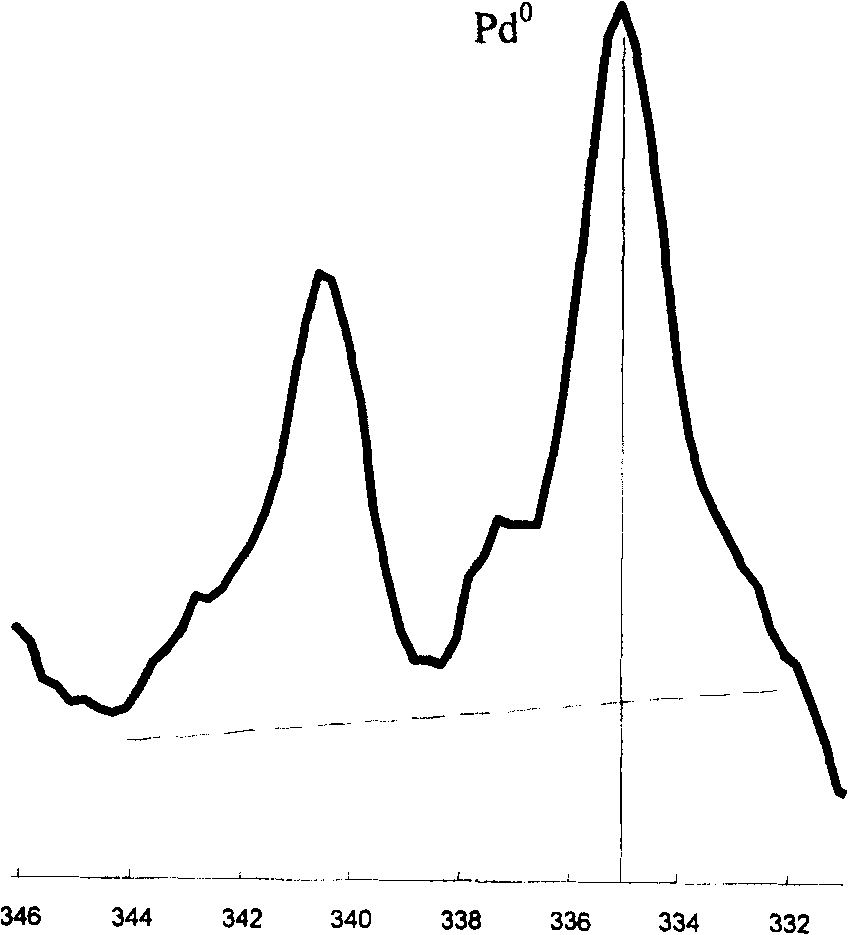

[0032] Step is the same as example 1, utilizes NH 4 OH (25%-28% mass fraction) adjusts the pH of the plating solution in step 5 to 11. The composition of the coating and the valence state of Pd were analyzed by XPS, and the atomic content of Pd on the surface of the catalyst was found to be 1.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com