Integrated bubble-free aeration biological composite film film-separation biological reactor

A bioreactor, bubble-free aeration technology, applied in the direction of sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve problems such as inability to guarantee treatment effect, inability to guarantee biofilm, poor operational stability, etc. , to achieve the effect of convenient and accurate control of aeration volume, reduction of membrane fouling, and improvement of oxygen transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

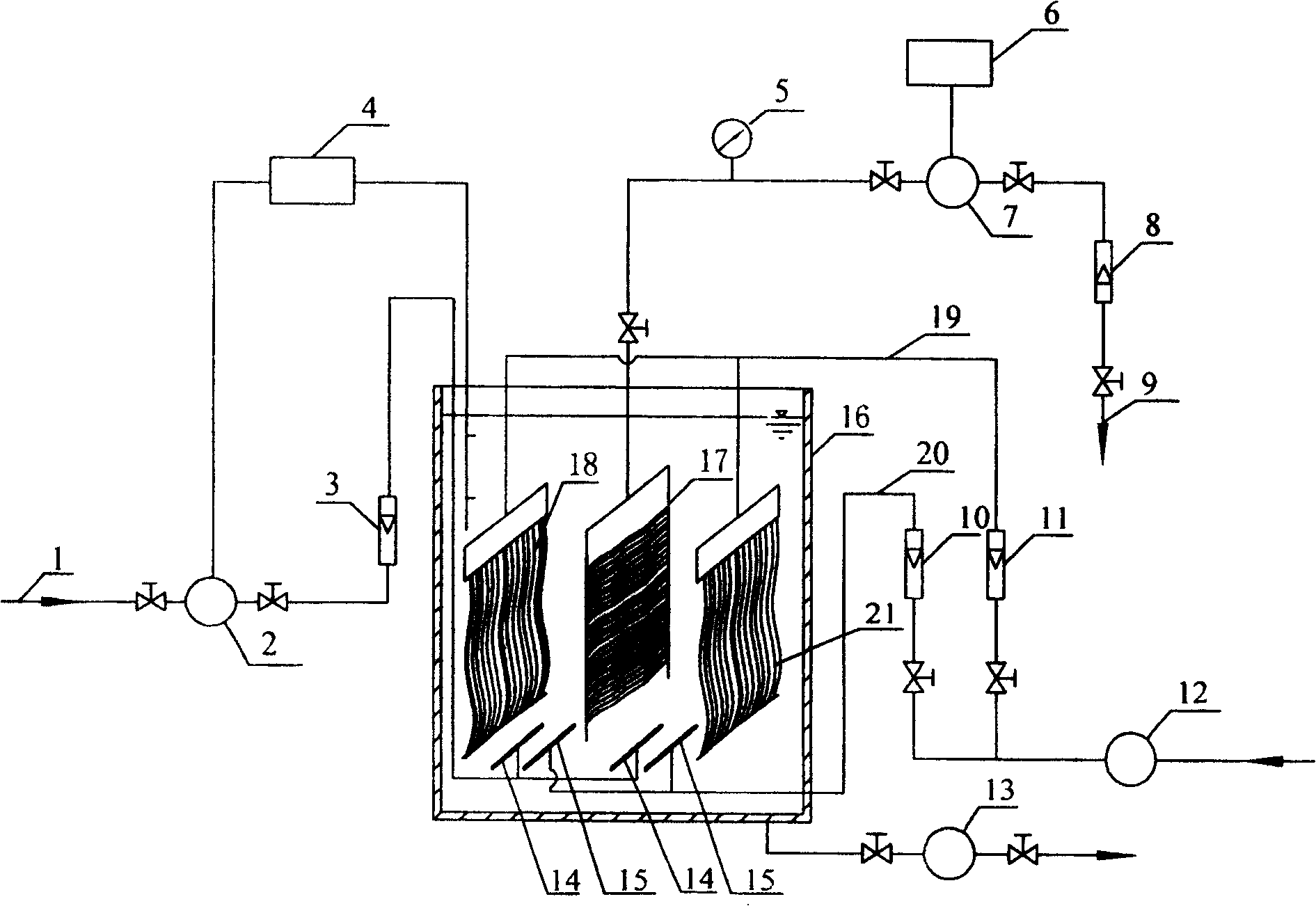

[0007] Specific implementation one: (see figure 1 ) This embodiment consists of a water inlet pipe 1, an inlet pump 2, a suction pump 7, a water outlet pipe 9, a blower 12, a sludge discharge pump 13, a perforated water distribution pipe 14, a perforated aeration pipe 15, a biochemical reactor 16, a solid-liquid separation membrane The assembly 17, the first bubble-free aeration biofilm assembly 18, the air inlet pipe 19 and the aeration connecting pipe 20 are composed of the solid-liquid separation membrane assembly 17 and the first bubble-free aeration biofilm assembly 18, which are respectively vertically arranged in the biochemical reactor. 16. The solid-liquid separation membrane module 17 and the first bubble-free aeration biological membrane module 18 are parallel to each other. The solid-liquid separation membrane module 17 is communicated with the water outlet pipe 9, and the suction pump 7 is connected in series on the water outlet pipe 9. The water distribution pipe...

specific Embodiment approach 2

[0008] Specific implementation two: (see figure 1 ) The difference between this embodiment and the first embodiment is that a second bubble-free aeration biofilm assembly 21 is added in the biochemical reactor 16 , and the second bubble-free aeration biofilm assembly 21 is arranged in the biochemical reactor 16 Inside and symmetrically arranged with the first bubble-free aeration biofilm assembly 18 . Other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation three: (see figure 1 ) In this embodiment, the upper ends of the solid-liquid separation membrane module 17 , the first bubble-free aeration biofilm module 18 and the second bubble-free aeration biofilm module 21 are respectively 30-40 cm lower than the water surface in the biochemical reactor 16 . Other compositions and connection relationships are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com