Seepage drainage method for tailing dam and seepage drainage pipe for use therein

A tailings dam and seepage pipe technology, which is applied in excavation, soil protection, construction, etc., can solve the problems of difficult construction, easy downward displacement, small seepage area, etc., and achieves low construction cost and maintenance cost. Good water permeability, ensure the effect of water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

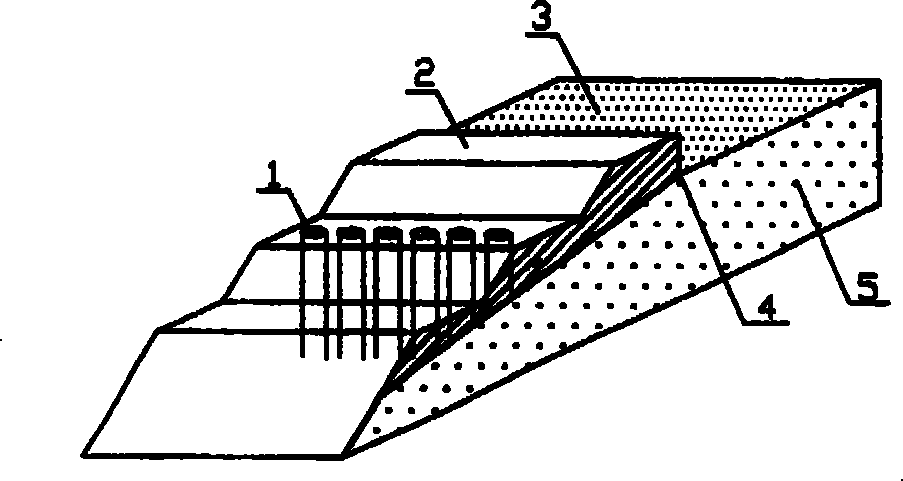

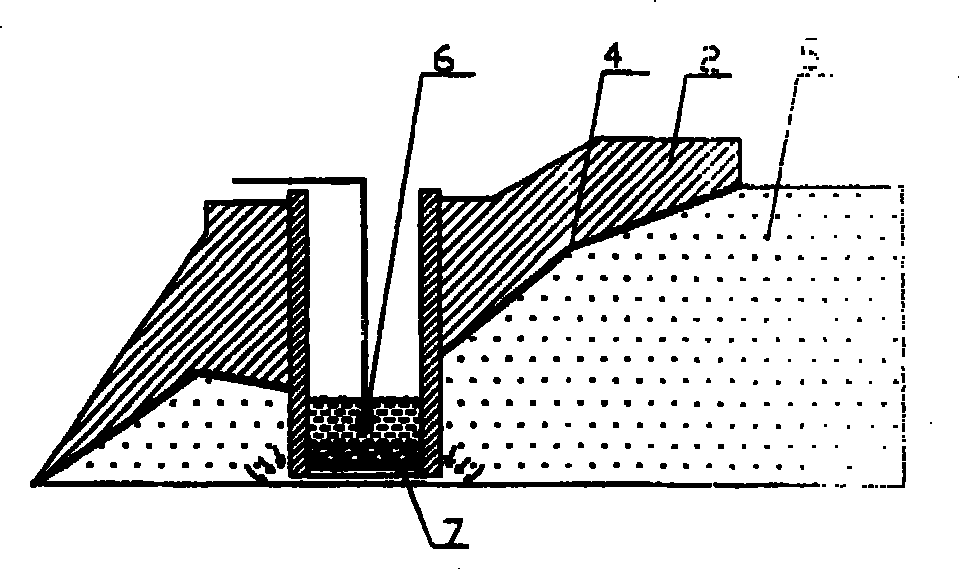

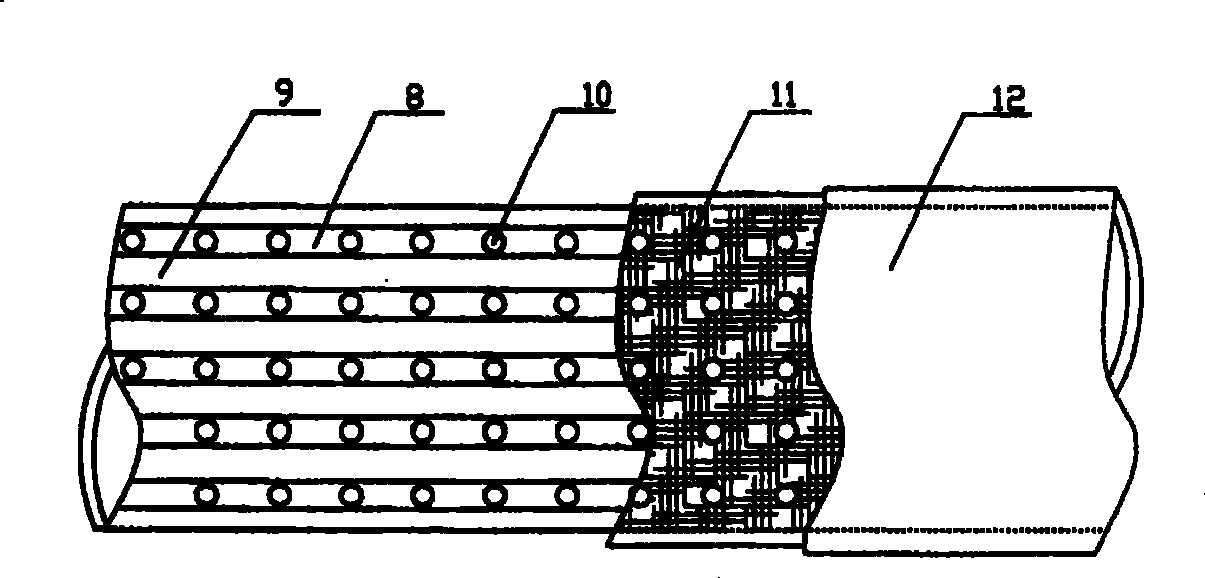

[0019] A method for drainage of tailings dam, comprising the following steps:

[0020] Drilling, including laying of drill pipes: on the tailings dam, use a horizontal directional drilling machine to drill holes according to the specified depth, angle, and direction to form a tunnel from the lower part of the dam body to the upper part of the dam body; at the same time, lay the drill pipes on the tailings In the borehole of the dam body;

[0021] Pipe pulling, including drainage pipe laying: connect the drill pipe laid in the tailings dam body with the end exposed outside the dam body to a reamer. To facilitate the laying of the drainage pipe in the next step, the reamer is connected with a universal joint, and the universal joint is connected with the head end of the special drainage pipe through a clamp, and then the drilling rig extracts the drill pipe from the tailings dam body, thereby The special drainage pipe is dragged into the tunnel drilled on the tailings dam;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com