Piston integrated measurement system

A comprehensive measurement and piston technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of unfavorable technological process quality control standard implementation system, the inability to record the measured dimensions in real time, low detection accuracy and detection efficiency, etc., and achieve the integration of management and control, Improve detection accuracy and production efficiency, facilitate the effect of quality management system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

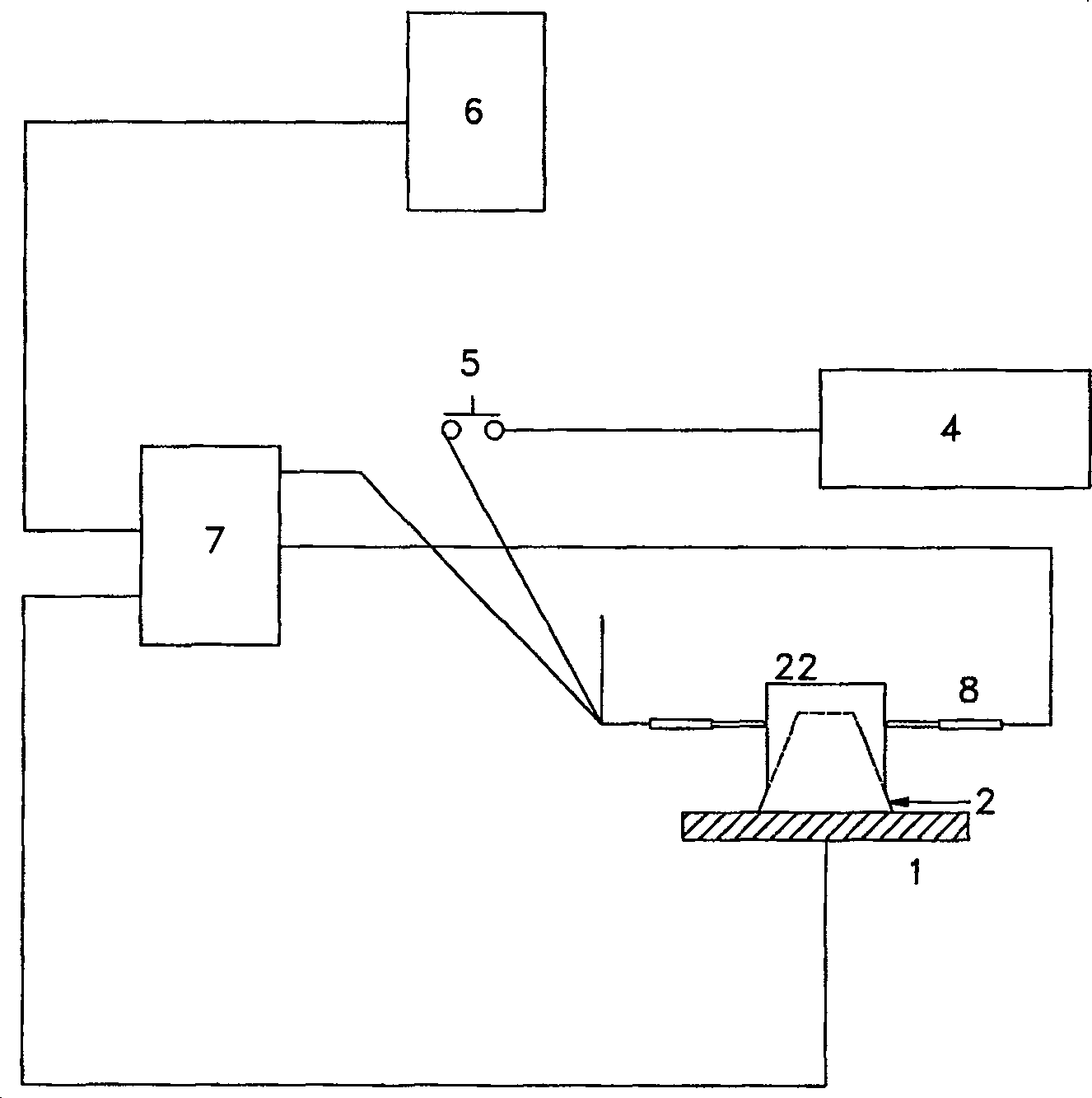

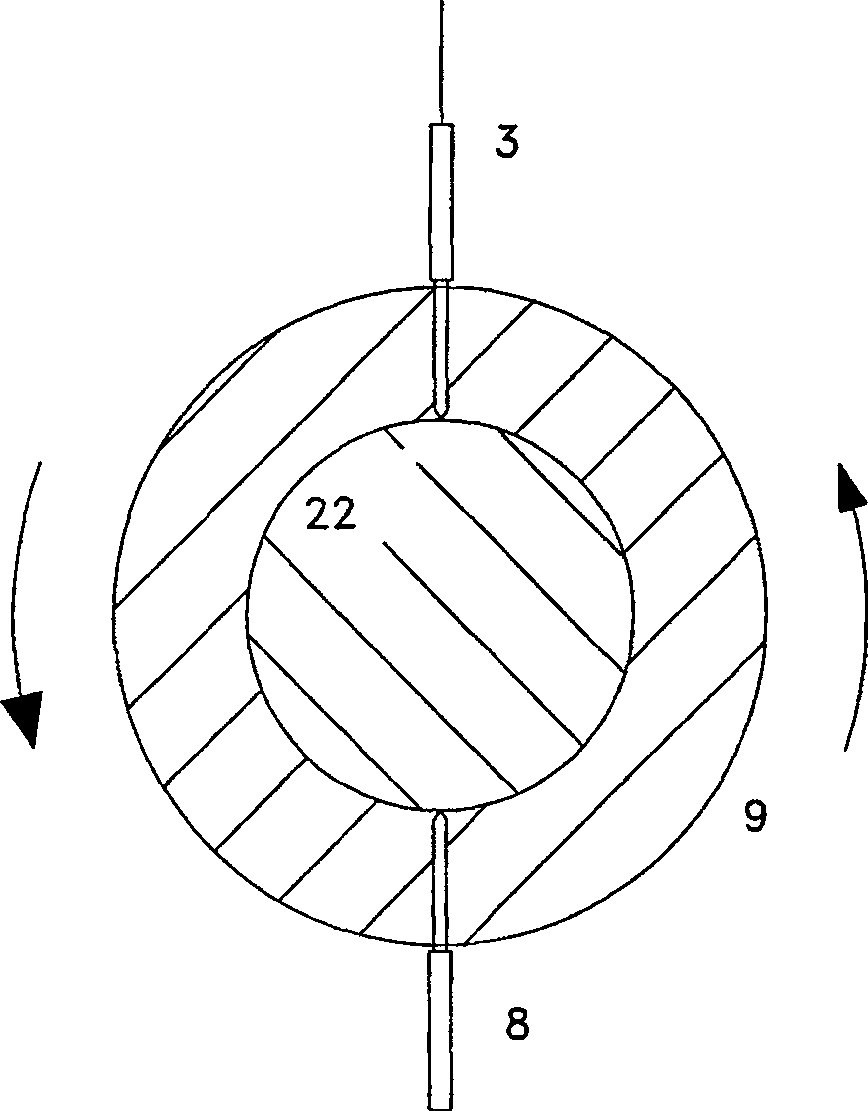

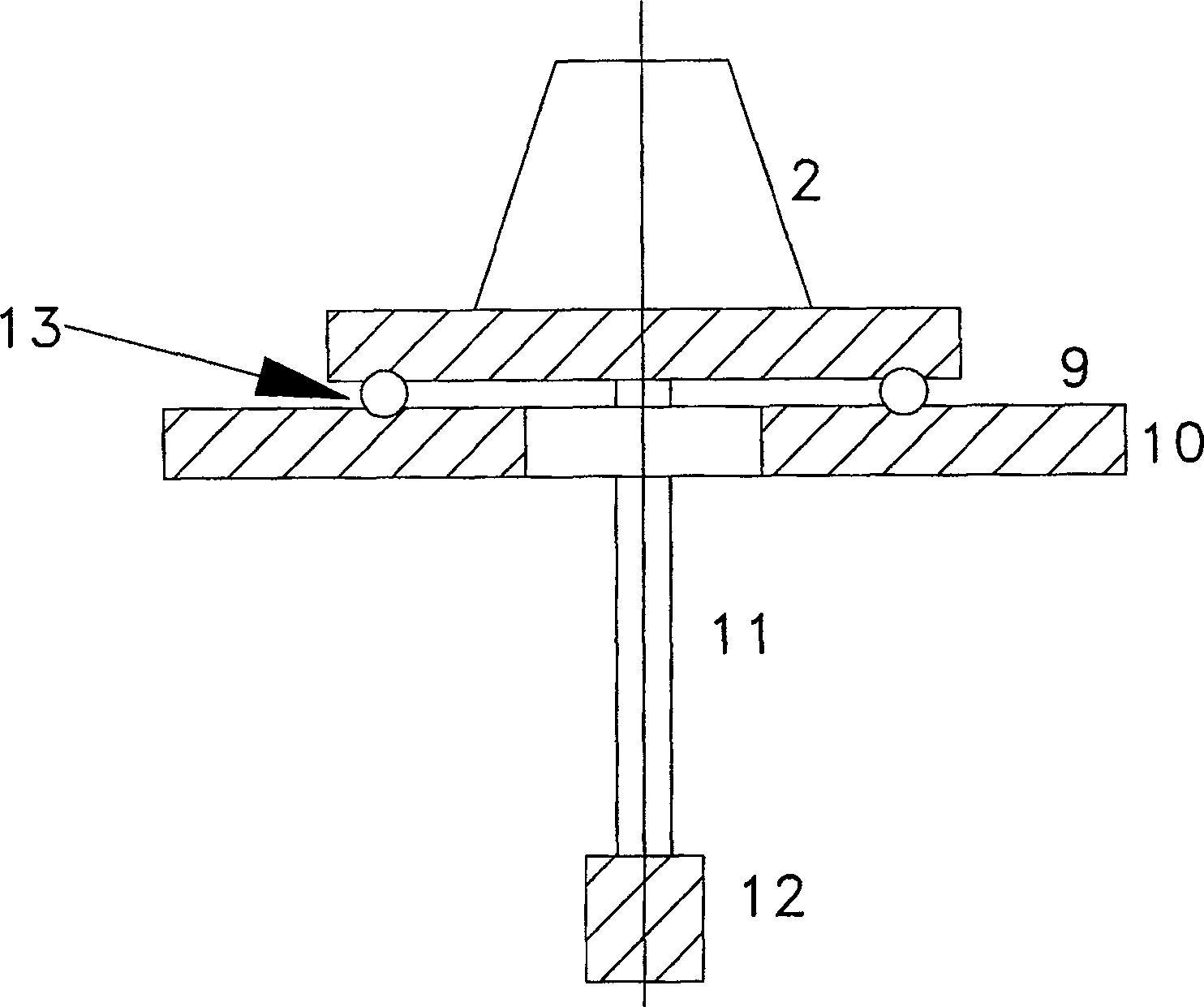

[0016] The present invention is mainly composed of a motor rotating device 1, a jig 2, a first displacement sensor 3, a pulse signal generator 4, a button 5, an industrial computer 6, an intelligent data acquisition and control device 7 and a second displacement sensor 8. Wherein the motor rotation transpose 1 is made up of rotating platform 9, fixed platform 10, stepper motor 11, rotating shaft 12, runner 13. And intelligent data acquisition and control device 7 are by single-chip microcomputer 14, first group, second group A / D converter 15, first group, second group amplifying circuit 16, stepper motor controller 17, keyboard display driver 18, display instrument 19, keyboard buttons 20 and RS485 interface 21.

[0017] Such as figure 1 Shown: place a jig 2 at the specified position, the jig 2 is a cone shape, the center of the jig 2 coincides with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com