Method for ingelligent optimizing procedure of semiconductor packing producing line

An intelligent optimization and semiconductor technology, applied in semiconductor/solid-state device manufacturing, instrumentation, adaptive control, etc., can solve problems such as complex and variable production systems, and few simulation studies on semiconductor packaging production lines, achieving fast convergence and machine average The effect of reasonable occupancy rate and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

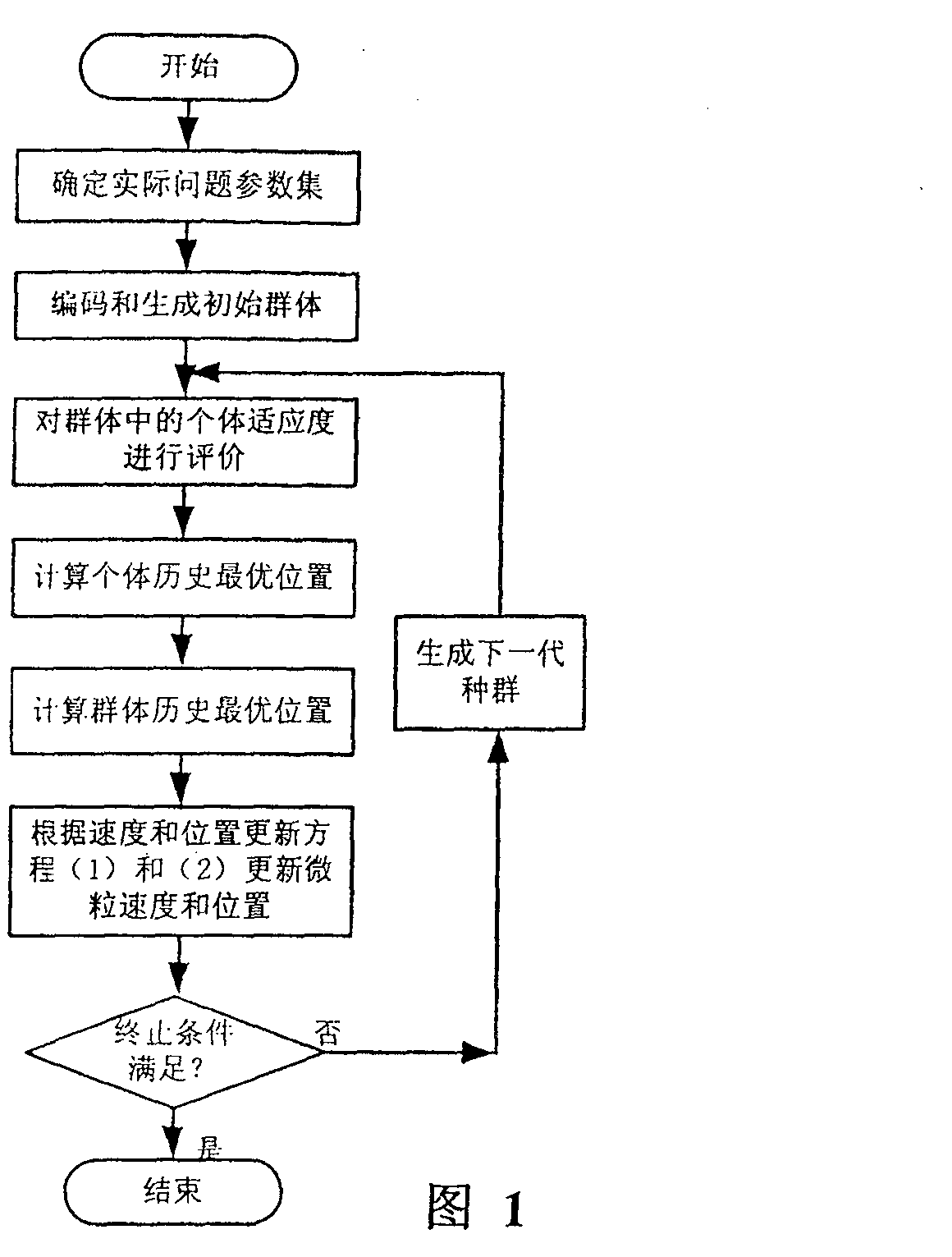

[0042] The present invention carries out the particle swarm optimization algorithm solution principle adopted in subproblem optimization solution is (referring to accompanying drawing 1):

[0043] The initial population is composed of randomly generated solutions, and the individuals in the population are called particles. The particles fly at a certain speed in the search space, and the speed can be dynamically adjusted according to the flying experience of itself and its companions. Assuming that the size of particle swarm is N, the coordinate position of particle i (i=1-N) in D, dimensional space can be expressed as x i =(x i1 , x i2 ,K,x id , KxiD ), the velocity of particle i is defined as the distance traveled by the particle in each iteration, with v i =(v i1 , v i2 ,K,v id , Kv iD )express. The flight velocity v of particle i in the dth (d=1-D) dimensional subspace id And the position updates of the particles are adjusted according to the following two equatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com