Self-adapting technique changing method for self-adapting focusing and leveling adjustment sensor system

A technology for focusing, leveling, and process change, which is applied in photolithographic process exposure devices, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve the problems of complicated scanning control, increased exposure failure rate and scrap rate, and low production efficiency, etc. problems, to achieve the effects of improving usability, production efficiency and yield, reducing measurement errors and system failure risks, and saving use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and examples.

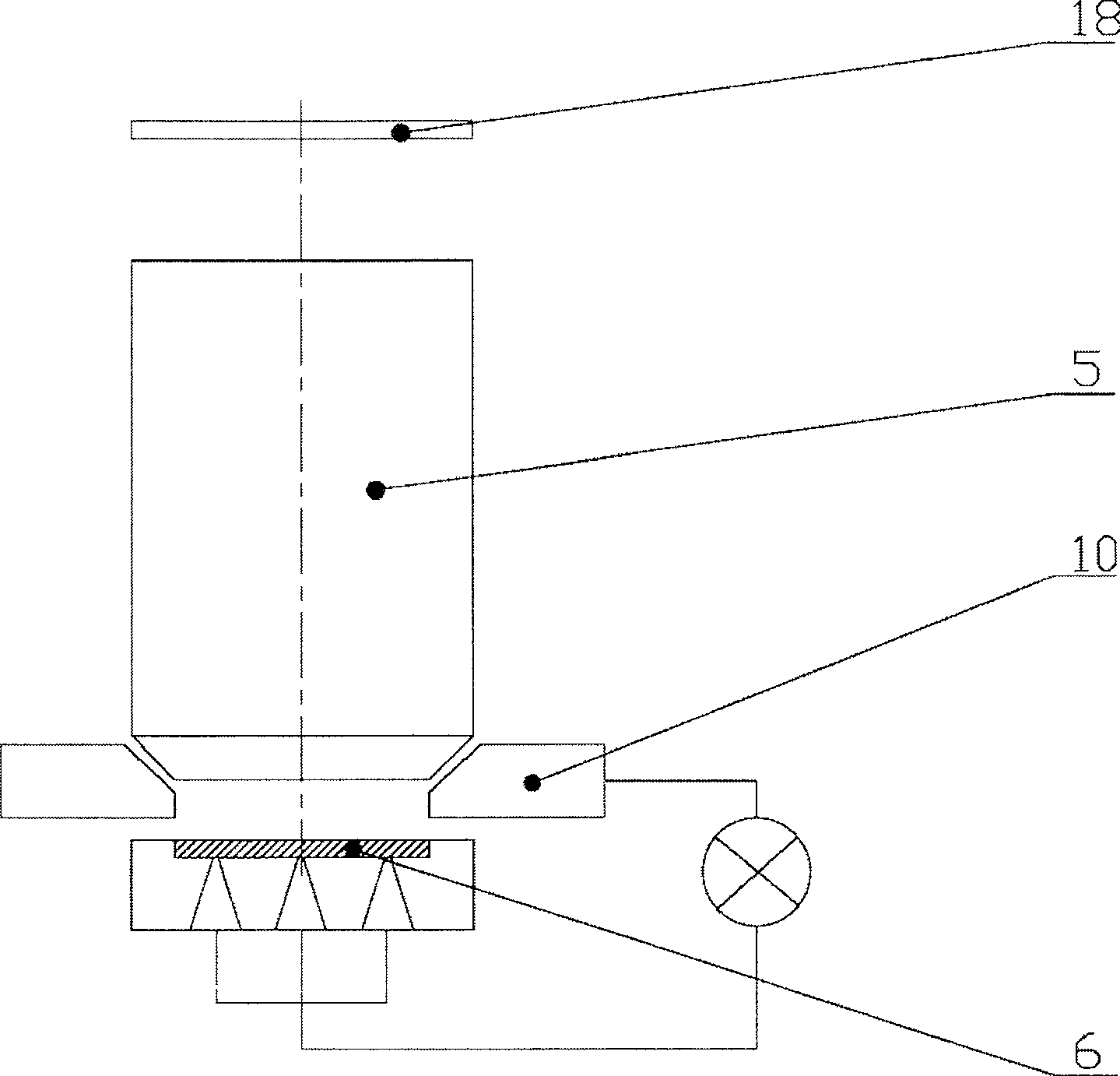

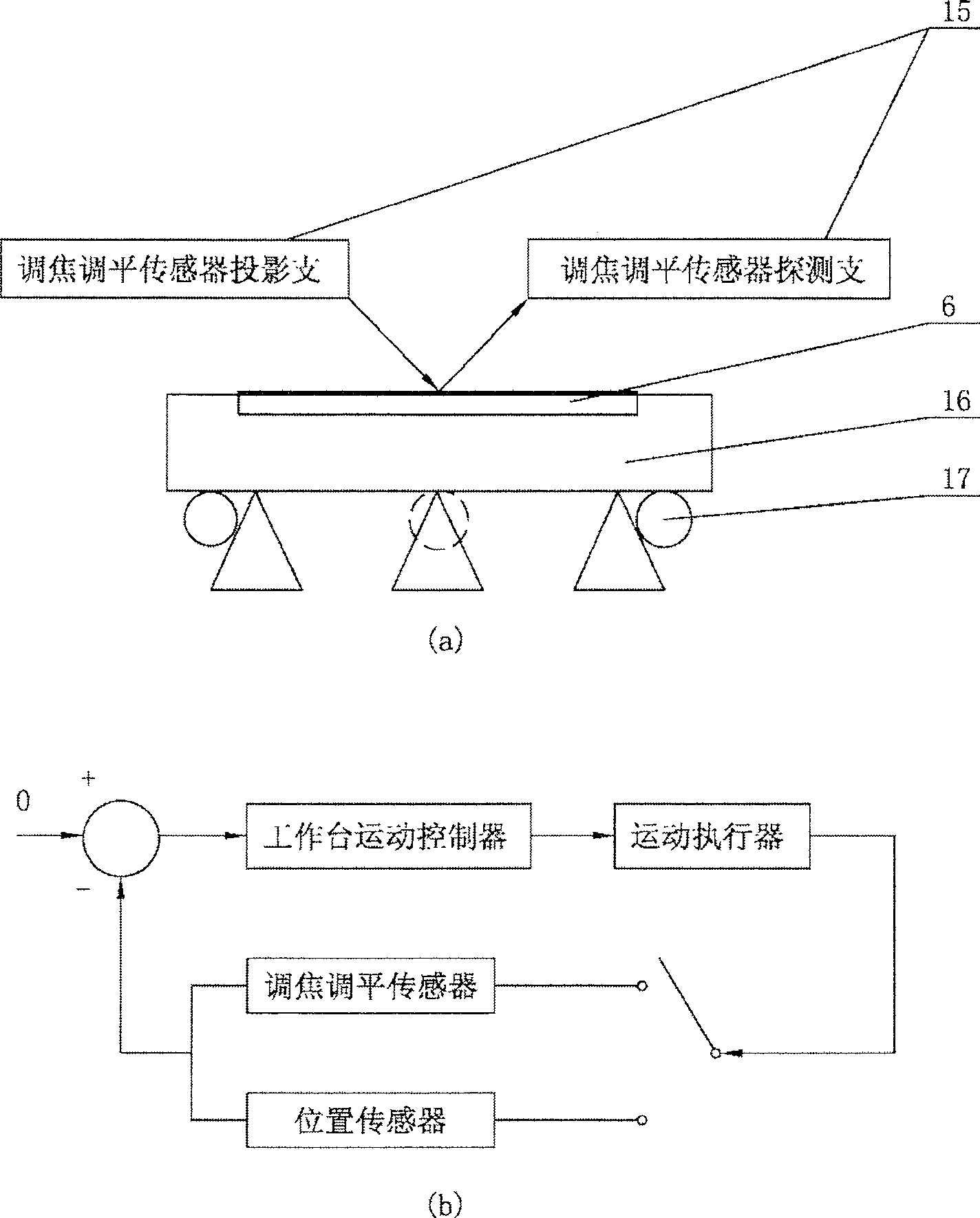

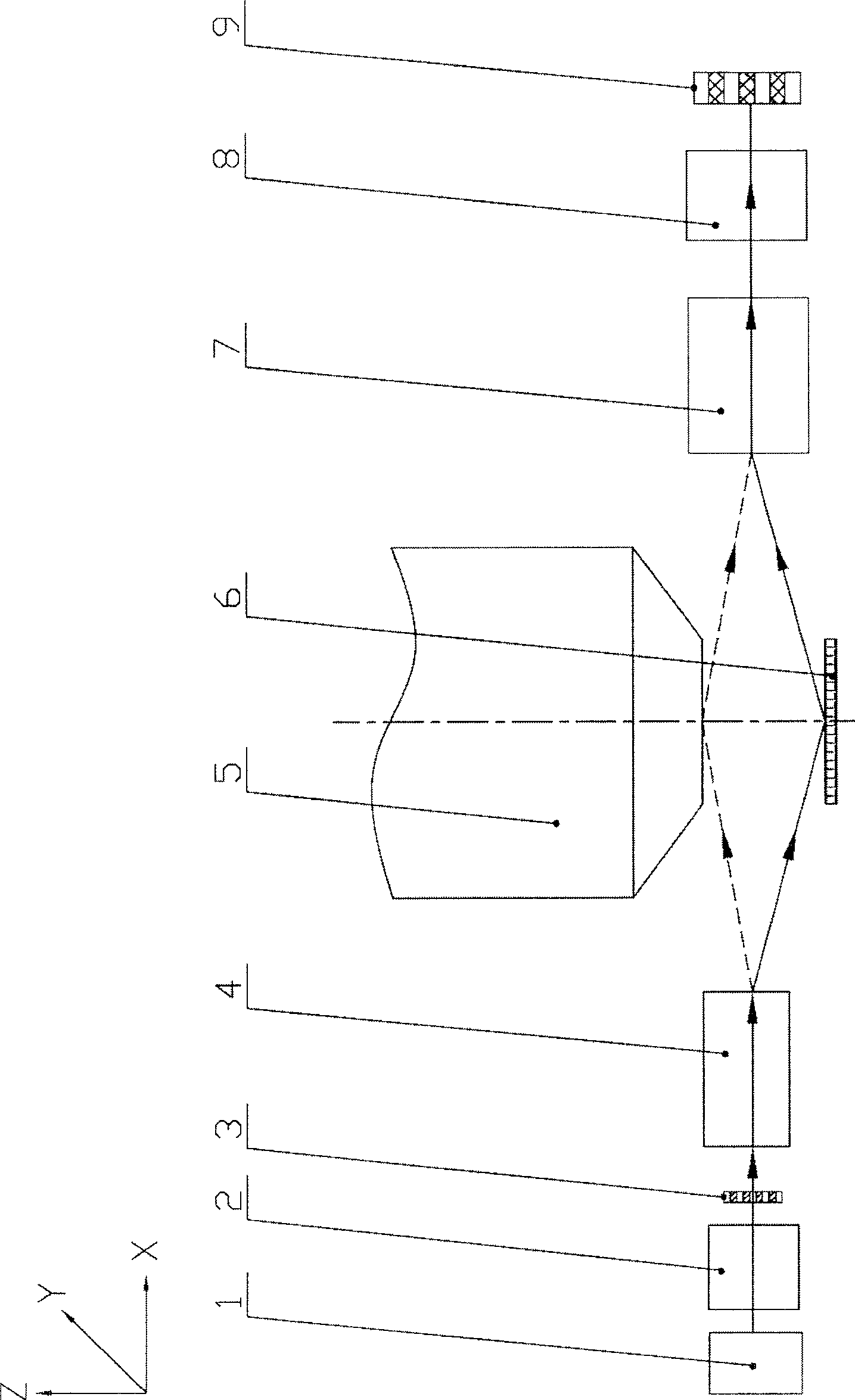

[0051] see image 3 , image 3 It is a structural schematic diagram of a focusing and leveling system based on photoelectric measurement. Such as image 3 As shown, the light emitted from the light source module 1 passes through the illumination optical module 2 for beam shaping, and then passes through the illumination spot mask 3 to generate a spot. The spot mask 3 is designed according to the shape and distribution of the spot that needs to be projected onto the measurement object (silicon wafer or the lower surface of the projection objective lens), and the projection relationship from the spot mask to the measurement object, so as to ensure that the measurement object can produce all Spot distribution is required. The light beam emitted from the spot mask 3 passes through the projection module 4 and then projects onto the measurement object. The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com