Technique of separating and recovering lighter hydrocarbons in refinery dried gas

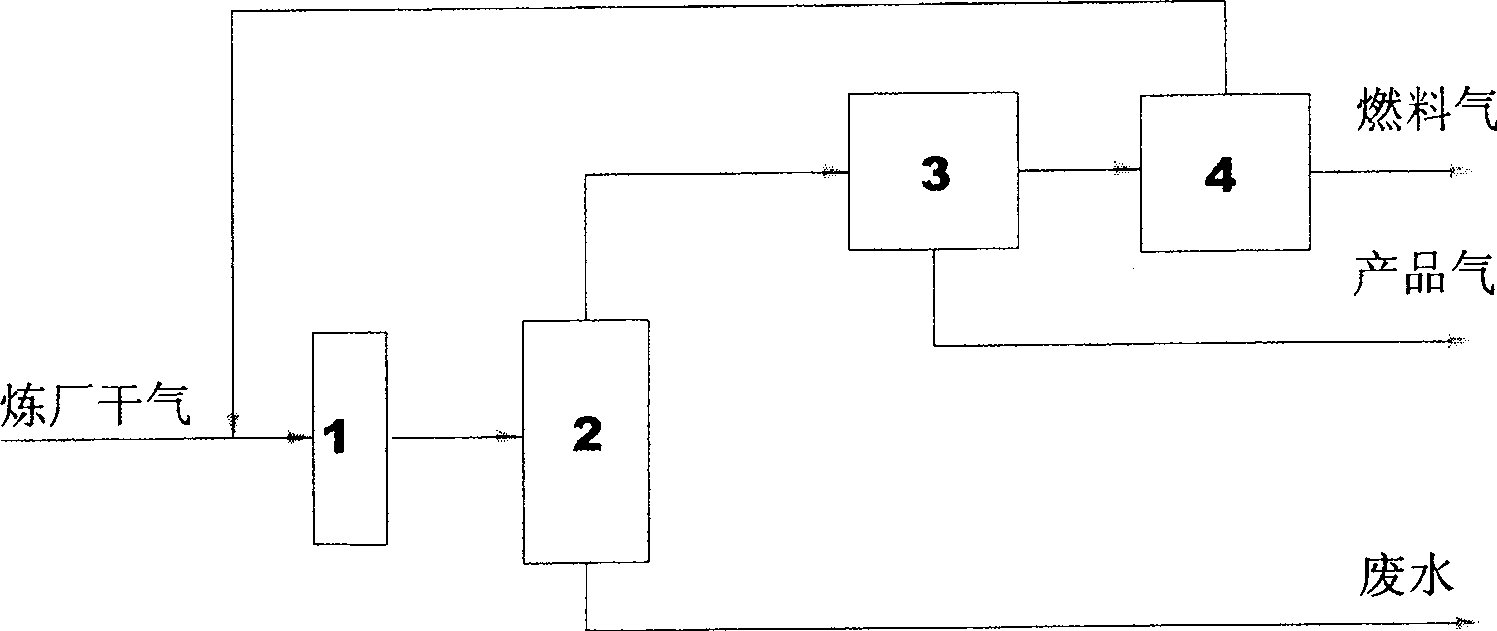

A technology for separation and recovery of dry gas from refineries, which is applied in the recovery of liquid hydrocarbon mixtures and the petroleum industry. It can solve problems such as complex processes, high operating costs, and large equipment, and achieve good separation and recovery effects, low operating costs, and compact equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

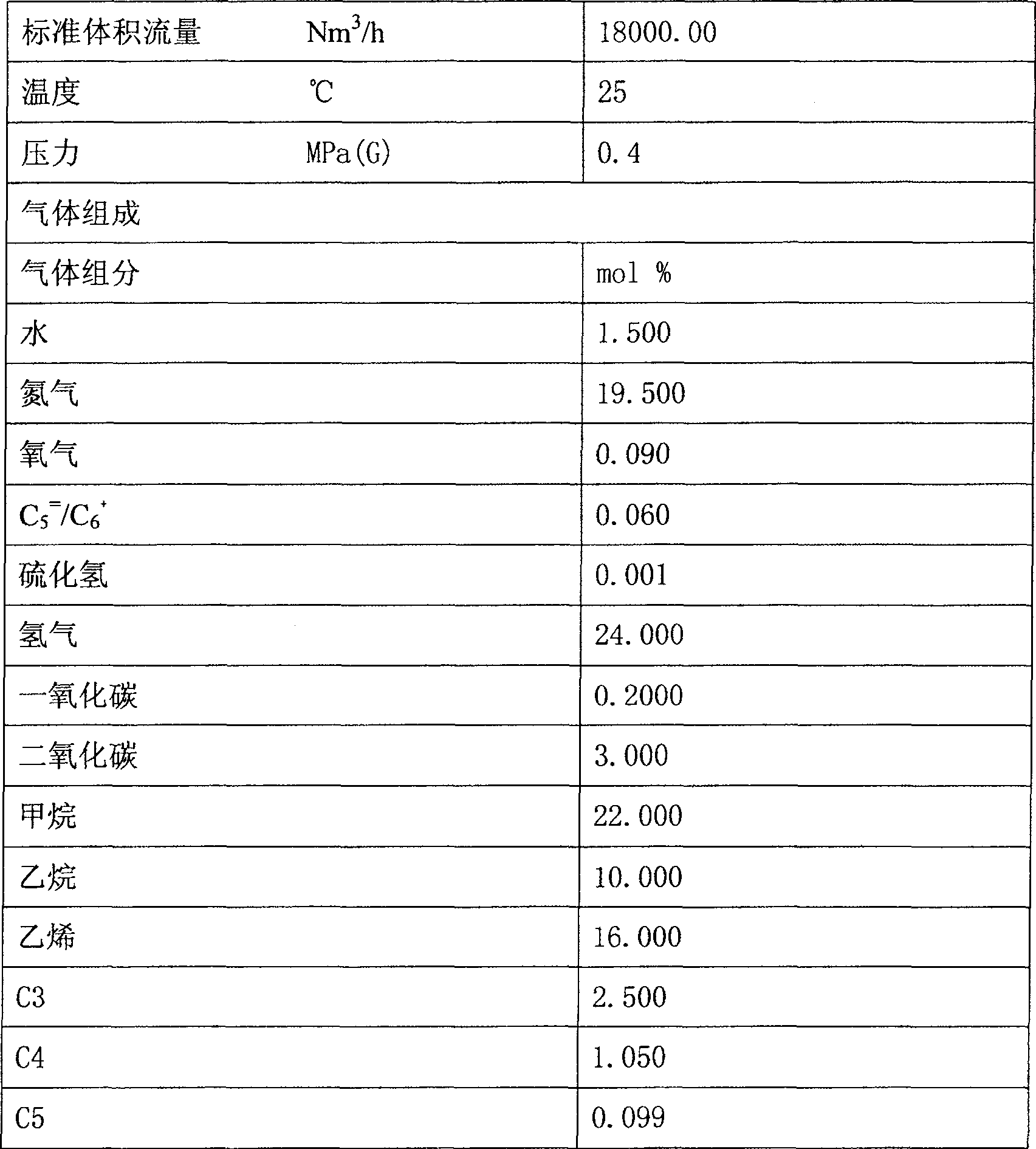

Examples

no. 4 example

[0018] In the fourth embodiment of the present invention, the inlet pressure of the dry gas in the refinery is 2.5 MPa, the inlet temperature of the first-stage organic vapor membrane separator 3 is 50°C, and the inlet temperature of the second-stage organic vapor membrane separator 4 is 35°C ; All the other are with embodiment 1. After testing, the recovery rate of ethylene was 93.0%, and the recovery rate of ethane was 93.5%.

[0019] In the fifth embodiment of the present invention, the inlet pressure of the dry gas in the refinery is 4.0 MPa, the inlet temperature of the first-stage organic vapor membrane separator 3 is 50°C, and the inlet temperature of the second-stage organic vapor membrane separator 4 is 35°C ; All the other are with embodiment 1. After testing, the recovery rate of ethylene was 95.0%, and the recovery rate of ethane was 94.5%.

no. 6 example

[0020] In the sixth embodiment of the present invention, the inlet pressure of the dry gas in the refinery is 2.0 MPa, the inlet temperature of the first-stage organic vapor membrane separator 3 is 40°C, and the inlet temperature of the second-stage organic vapor membrane separator 4 is 20°C ; All the other are with embodiment 1. After testing, the recovery rate of ethylene was 93.0%, and the recovery rate of ethane was 93.0%.

[0021] In the seventh embodiment of the present invention, the inlet pressure of the dry gas in the refinery is 2.9MPa, the inlet temperature of the first-stage organic vapor membrane separator 3 is 35°C, and the inlet temperature of the second-stage organic vapor membrane separator 4 is 20°C ; All the other are with embodiment 1. After testing, the recovery rate of ethylene was 93.0%, and the recovery rate of ethane was 93.0%.

[0022] In the eighth embodiment of the present invention, the inlet pressure of the dry gas in the refinery is 1.8MPa, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com