Batch synthesis method of hollow nanometer/micrometer zinc oxide ball

A technology of zinc oxide nanometer and synthesis method, applied in the direction of zinc oxide/zinc hydroxide, etc., to achieve the effect of easy synthesis process and improvement of room temperature luminescence performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

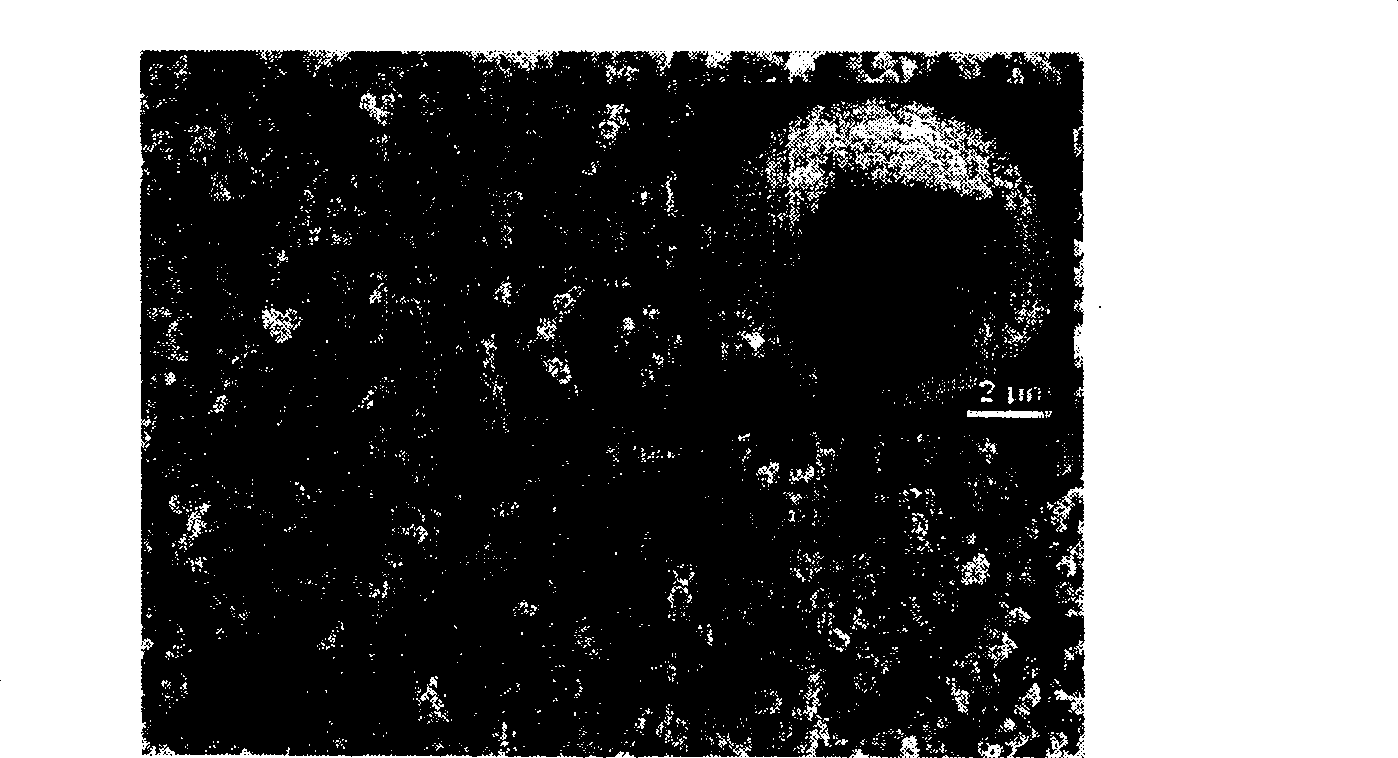

[0021] The diameter of the reactor is 20 mm, and the length of the electric furnace is 200 mm. The flow rate of argon (99.9%) is 115 sccm, the flow rate of oxygen (99.9%) is 0.1 sccm, graphite material is used as the container and deposition substrate of zinc powder, the particle size of zinc powder is less than 25 μm (pure zinc content >99.2%), the thickness of zinc powder is placed About 1.5mm. The reaction temperature is 680°C, and the reaction time is 20 minutes. Prepared in batches to obtain pure hollow spherical and hemispherical zinc oxide, the form of the product is as follows figure 1 shown.

Embodiment 2

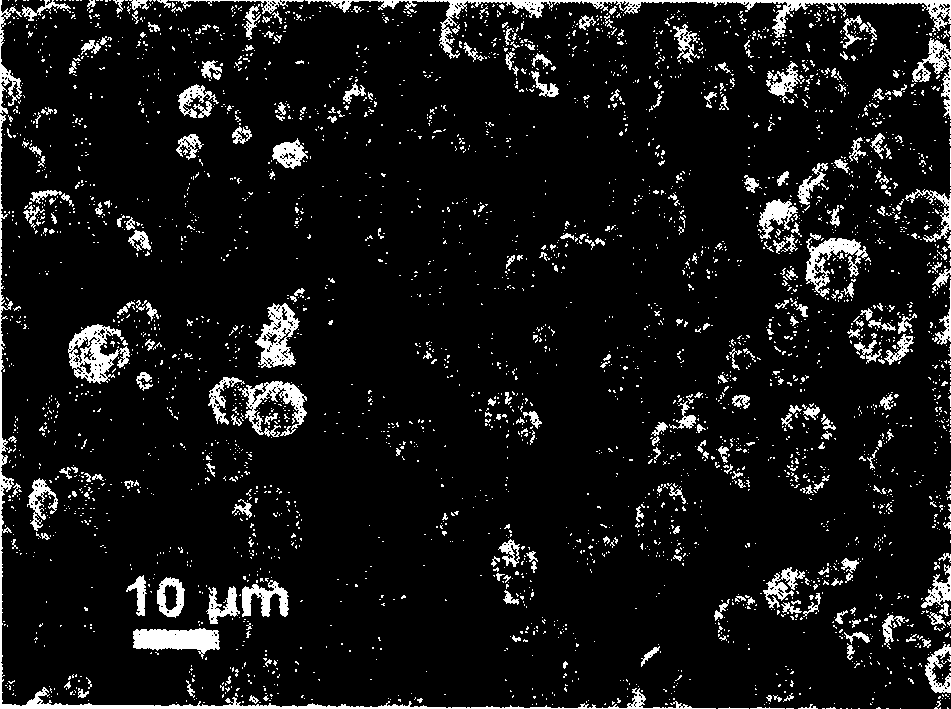

[0023] The diameter of the reactor is 20 mm, and the length of the electric furnace is 200 mm. The flow rate of argon (99.9%) is 80 sccm, and the flow rate of oxygen (99.9%) is 8 sccm. The graphite material is used as the container and deposition substrate of the zinc powder. The particle size of the zinc powder is less than 25 μm (pure zinc content> 99.2%). 3mm; reaction temperature 600°C, reaction time 40min. The sea urchin-shaped zinc oxide hollow sphere material was prepared in batches. The material is an assembly of zinc oxide nanowires and hollow spheres. The shape of the product is as follows: figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com