Method for recovering benzene and toluene

A technology of benzene, toluene and toluene, applied in organic chemistry, distillation purification/separation, etc., can solve the problems of high temperature, increased investment, high operating temperature, etc., and achieve the effects of reduced energy consumption, less investment, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

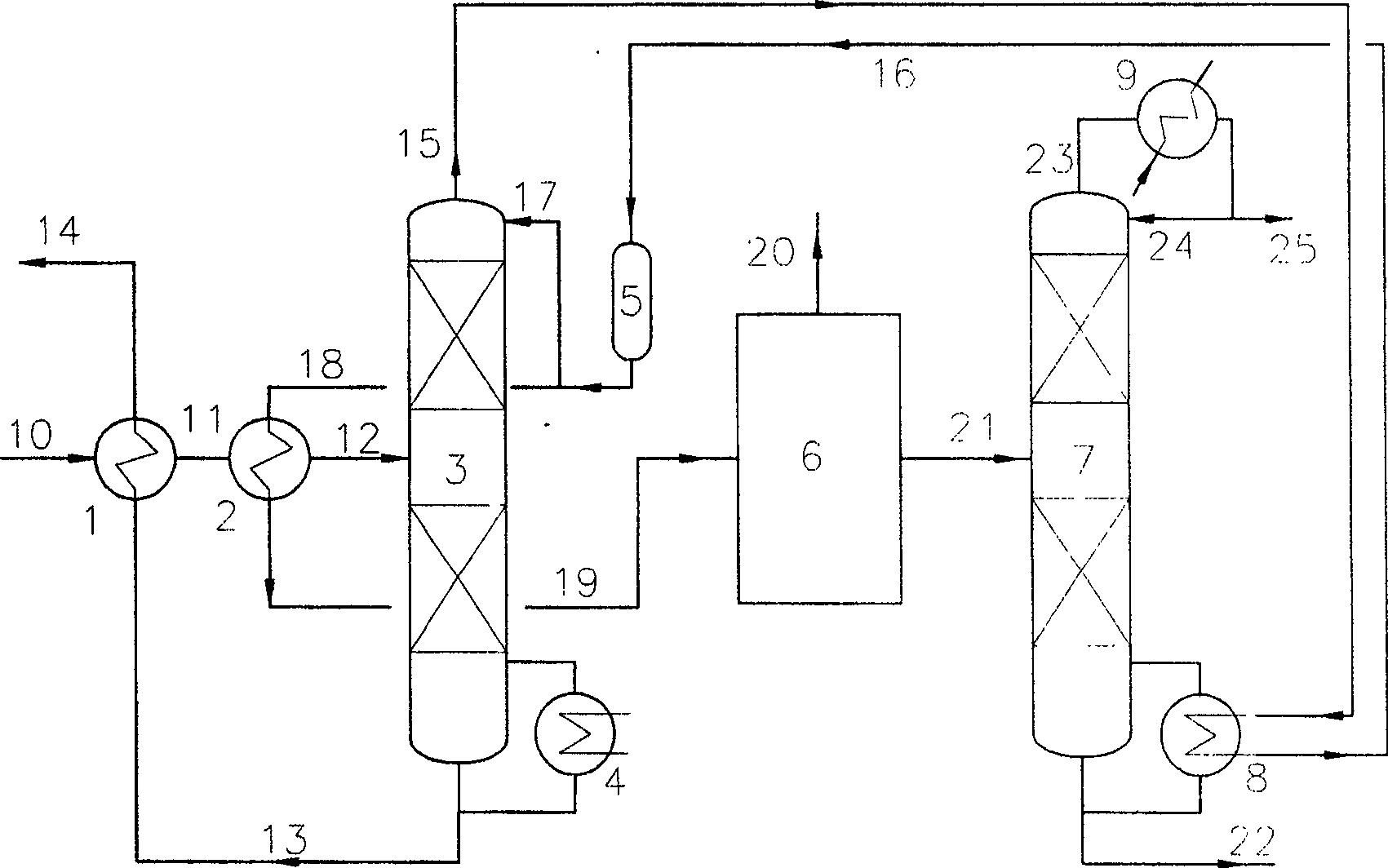

[0020] The method technological process of present embodiment reclaiming benzene and toluene is as figure 1 As shown, it mainly includes the following steps:

[0021] (1), pre-rectification: the raw material mixture 10 containing aromatics is preheated by heat exchangers 1 and 2 and enters the middle part of the pre-rectification tower 3; the raw material mixture 10 is 2947.85kg / h, wherein n-pentane 2.8kg / h h, cyclopentane 48.3kg / h, n-hexane 17.30kg / h, cyclohexane 14.25kg / h, n-heptane 4.4kg / h, methylcyclohexane 8.70kg / h, benzene 2197.64kg / h, Toluene 439.71kg / h, dimethylcyclohexane 3.85kg / h, n-octane 0.65kg / h, ethylcyclohexane 2.3kg / h, carbon 8 aromatics 162.95kg / h, carbon 9 or more hydrocarbons 45kg / h ; This pre-rectification tower 3 is a plate tower, and operating pressure is 0.3MPa (G) in the tower 3, and tower top temperature is 140 ℃, and feed position is in tower middle upper part, and reflux ratio R=1.3; From pre-rectification tower 3 Extract xylene and other substance...

Embodiment 2

[0030] The method technological process of present embodiment reclaiming benzene and toluene is the same as embodiment 1, and difference is that there is following difference in operating condition in each tower:

[0031] (1), the pre-rectification tower 3 is a packed tower, the operating pressure in the tower 3 is 0.1MPa (G), the tower top temperature is 107 ℃, and the reflux ratio is 1.05; the raw material mixture 10 is 2704.65kg / h, wherein n-pentane 2.8kg / h, cyclopentane 30.5kg / h, n-hexane 18.5kg / h, cyclohexane 13.75kg / h, n-heptane 4.0kg / h, methylcyclohexane 10.40kg / h, benzene 1830.50kg / h, toluene 550.60kg / h, dimethylcyclohexane 4.00kg / h, n-octane 0.80kg / h, ethylcyclohexane 2.5kg / h, carbon 8 aromatics 180.80kg / h, carbon 9 or more hydrocarbons 55.50kg / h;

[0032] (2), benzene-toluene separation tower 7 is a packed tower, the operating pressure is-0.05MPa(G), and the temperature at the bottom of the tower is 88°C.

[0033] The mixed solution 13 discharged from the bottom of ...

Embodiment 3

[0039] The method technological process of present embodiment reclaiming benzene and toluene is also identical with embodiment 1, and difference is that there is following difference in operating condition in each tower:

[0040] (1), the pre-rectification tower 3 is a packed tower, the operating pressure in the tower 3 is 0.5MPa (G), the tower top temperature is 157 ℃, and the reflux ratio is 1.45; the raw material mixture 15 is 2961.65kg / h, wherein n-pentane 2.5kg / h, cyclopentane 55.05kg / h, n-hexane 18.00kg / h, cyclohexane 15.15kg / h, n-heptane 4.8kg / h, methylcyclohexane 9.00kg / h, benzene 2300.90kg / h, toluene 360.50kg / h, dimethylcyclohexane 4.00kg / h, n-octane 0.55kg / h, ethylcyclohexane 2.7kg / h, carbon 8 aromatics 150.50kg / h, carbon 9 or more hydrocarbons 38kg / h;

[0041] (2), benzylbenzene separation tower 7 is a plate tower, the operating pressure is 0.10MPa (G), the temperature at the bottom of the tower is 138 ° C, and the reflux ratio is 1.3.

[0042] Pre-rectification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com