Distribution transformer winding material testing system and method

A distribution transformer and test system technology, applied in the direction of material analysis, instruments, and measuring devices through electromagnetic means, can solve problems such as poor measurement results, lack of theoretical derivation, and complicated operations, so as to reduce time, improve detection efficiency, The effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

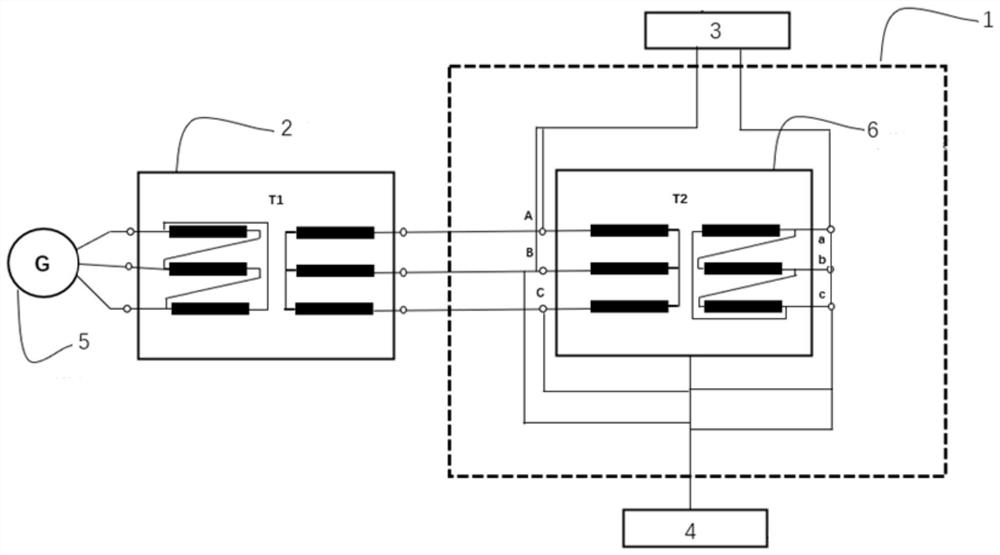

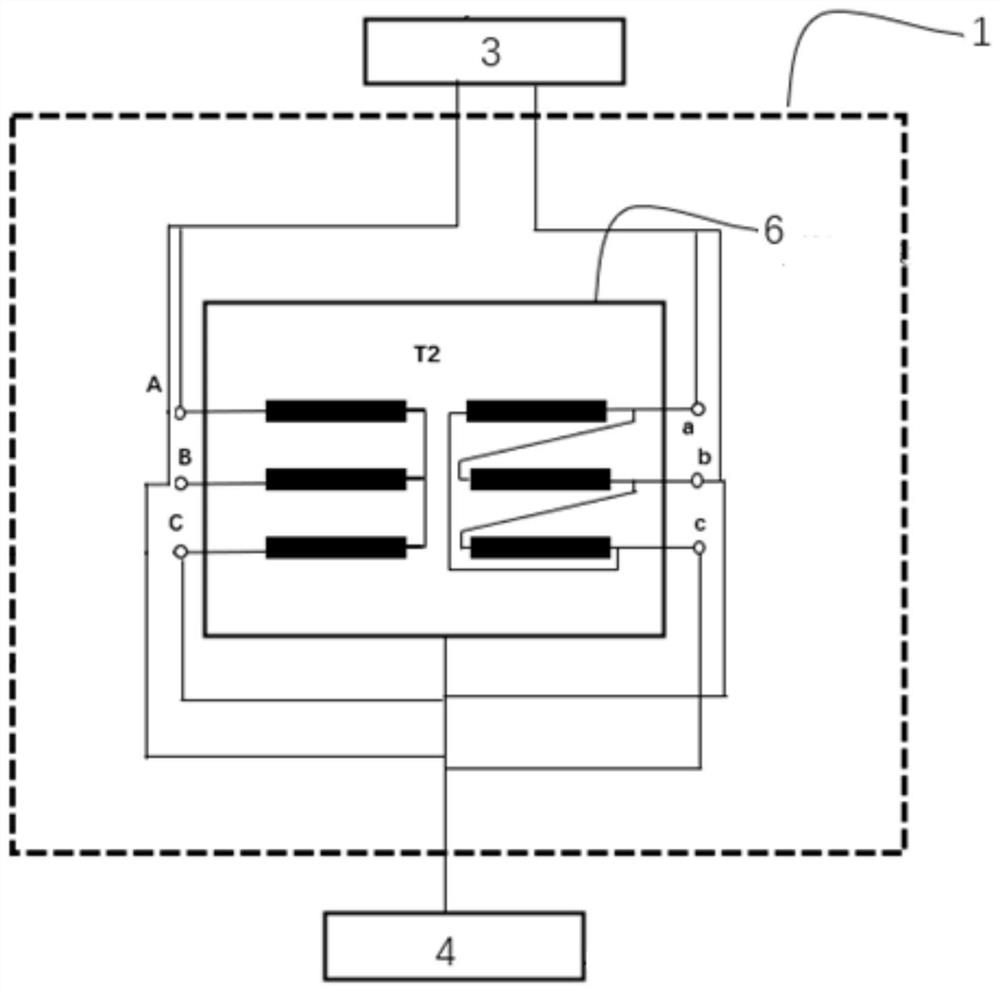

[0044] Embodiment 1 of the present invention provides a distribution transformer winding material testing system, such as figure 1 As shown, the system includes a temperature control device 1, a DC resistance test device 3, a temperature acquisition device 4, a transformer to be tested 6 and a test transformer 2;

[0045] The temperature regulating device 1 adopts an electric heating oven. During the test, the high and low voltage windings of the transformer to be tested 6 are heated and heated, and any two endpoints of the high and low voltage groups of the transformer to be tested are respectively connected to the DC resistance testing device 3 and Temperature acquisition device 4, wherein, said DC resistance testing device 3 comprises a test current generator and a dual-channel tester, and said test current generator can simultaneously measure the high and low voltage resistances of transformers through a dual-channel tester, said The temperature acquisition device 4 includ...

Embodiment 2

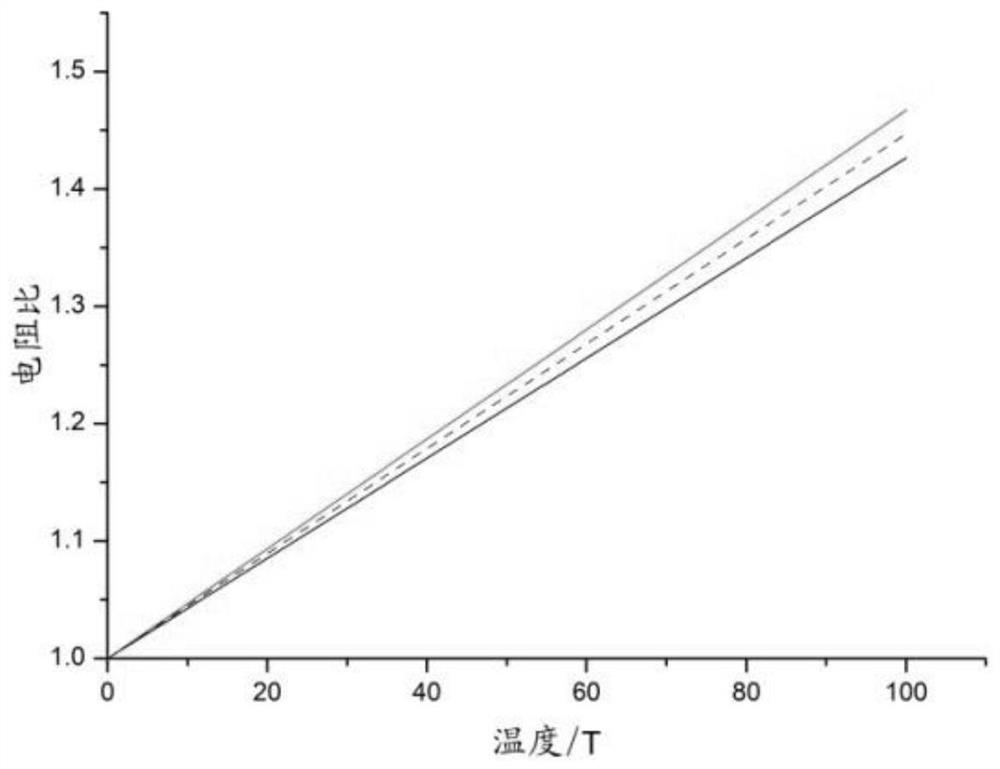

[0049] Embodiment 2 of the present invention provides a method for testing the winding material of a distribution transformer based on the test system provided in Embodiment 1 above. The test method includes the following steps:

[0050] S1: Short-circuit the terminals of the low-voltage group of the transformer 6 to be tested, and connect the terminals of the high-voltage group to the high-voltage group terminals of the test transformer 2 respectively, adjust the output current of the test transformer 2 according to the size of the transformer 6 to be tested, and quickly heating;

[0051] When the temperature of the temperature test point of the transformer 2 to be tested is higher than the minimum value of the balance temperature required to measure the resistance, stop the output current of the test transformer 2, and disconnect the terminal connection of the low-voltage group of the transformer 6 to be tested at the same time, and enter the temperature balance adjustment s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com