High efficiency polycarbonate / ABS composition and its application

A technology of polycarbonate and composition, which is applied in the field of polycarbonate/ABS composition, can solve the problem that the performance of polycarbonate/ABS composition cannot fully meet high-performance products, achieve excellent flow performance, and ensure safe use , the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

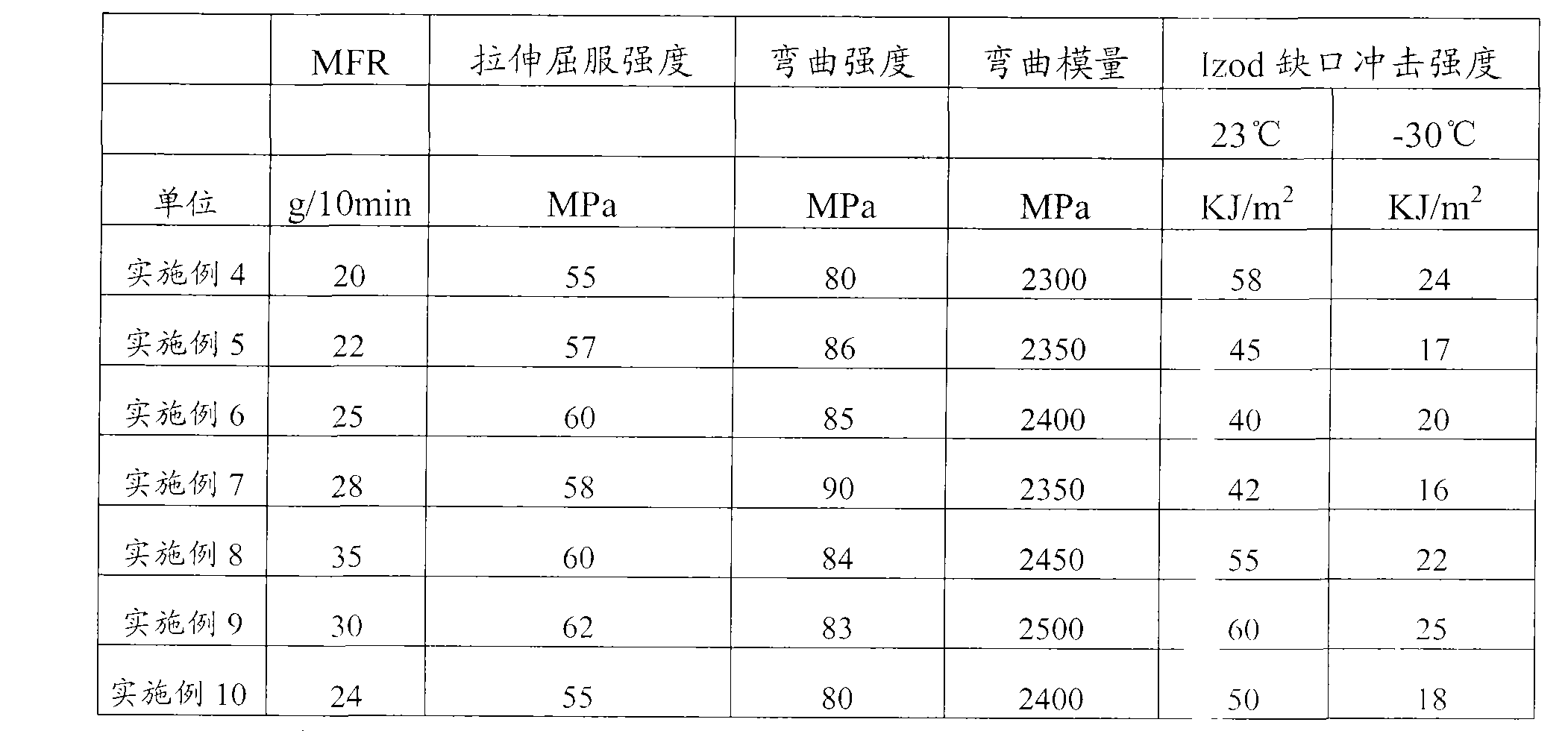

[0030] The components of the composition in this embodiment are: 20 kg of polycarbonate, 45 kg of ABS, 3 kg of acrylonitrile-styrene copolymer (AS) compatibilizer, 10100.2 kg of antioxidant, and 0.2 kg of lubricant pentaerythritol stearate. Kg; among which polycarbonate has a melt index of 8g / 10min, produced by BAYER, ABS is a B440 brand product with a butadiene content of 40% produced by GE, AS compatibilizer is produced by DuPont, and antioxidant is Swiss steam Pakistan company, the lubricant is produced by ICI company.

[0031] The above components are mixed uniformly, and then extruded and granulated with a twin-screw extruder, and the processing temperature is: 260°C (plasticizing section).

[0032] The product has been tested and the performance is as follows: MFR22g / 10min, tensile yield strength 58MPa, bending strength 80MPa, bending modulus 2400MPa, Izod notched impact strength 23℃, 43KJ / m 2 , / -30℃,16KJ / m 2 .

[0033] The polycarbonate / ABS composition of this embodiment can ...

Embodiment 2

[0035] The components of the composition of this embodiment are: polycarbonate 6.5 kg, ABS 2.8 kg, compatibilizer 0.5 kg, antioxidant 168 is 0.3 kg, lubricant montanic acid ester is 0.1 kg; the polycarbonate melt index is 6 g / 10min, produced by GE, ABS is a B338 product with a butadiene content of 65% produced by GE, the compatibilizer acrylic grafted AS copolymer is produced by Mitsubishi, and the antioxidant is Ciba of Switzerland.

[0036] The above components are mixed uniformly, and then extruded and granulated with a twin-screw extruder, and the processing temperature is: 250°C (plasticizing section).

[0037] The product has been tested and the performance is as follows: MFR20g / 10min, tensile yield strength 60MPa, bending strength 85MPa, bending modulus 2300MPa, Izod notched impact strength 23℃, 40KJ / m 2 , / -30℃, 18KJ / m 2 .

[0038] The polycarbonate / ABS composition of this embodiment can be used as the raw material of the mobile phone shell. The mobile phone produced is su...

Embodiment 3

[0040] The components of the composition of this embodiment are: 90 kg of polycarbonate, 10 kg of ABS, 6 kg of AS compatibilizer, 0.3 kg of antioxidant, and 0.3 kg of lubricant PE wax; the melt index of polycarbonate is 12g / 10min, produced by Teijin Chemical Co., Ltd., and ABS is a B336 brand product with a butadiene content of 60% produced by GE.

[0041] The above components are mixed uniformly, and then extruded and granulated with a twin-screw extruder, and the processing temperature is: 270°C (plasticizing section).

[0042] The product has been tested and the performance is as follows: MFR24g / 10min, tensile yield strength 55MPa, flexural strength 86MPa, flexural modulus 2350MPa, Izod notched impact strength 23℃, 45KJ / m 2 , / -30℃, 18KJ / m 2 .

[0043] The polycarbonate / ABS composition of this embodiment can be used as the raw material of the mobile phone shell. The mobile phone produced is subjected to the whole machine impact test: the steel ball (special for the whole mobile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com