Araneose hollow optical fiber

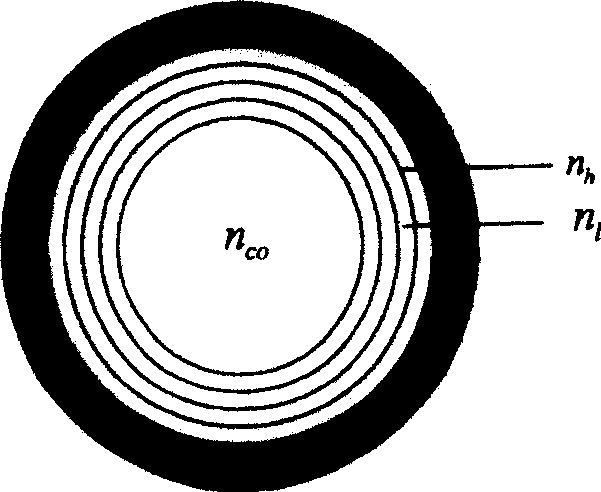

A technology of hollow-core optical fiber and spider web, which is applied in the direction of cladding optical fiber, optical waveguide and light guide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

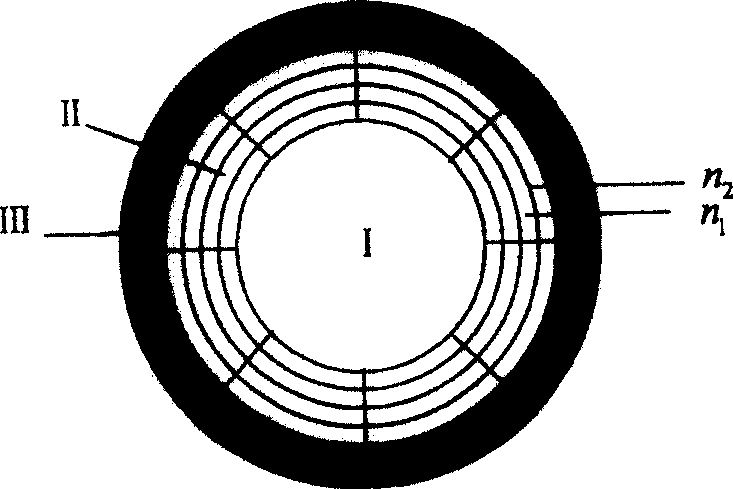

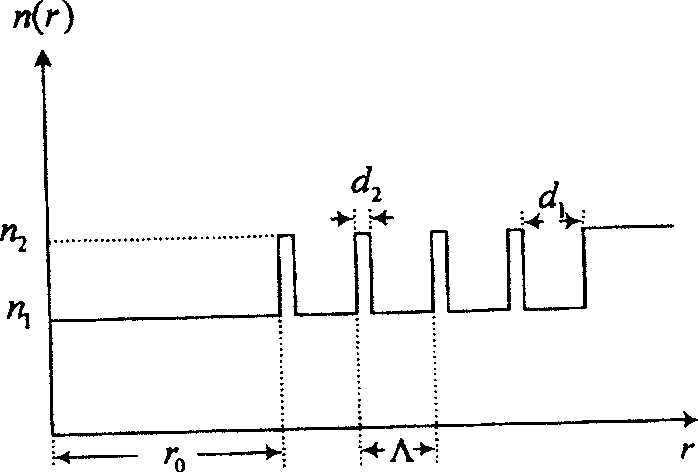

[0018] In this embodiment, it is to realize as figure 2 A spider-web-like hollow-core fiber with the structure shown. Its parameter is n 1 = 1 (air), n 2 =1.49(PMMA), d 1 = 0.80 μm, d 2 =0.25μm, Λ=1.05μm, r 0 =10 μm, N=4, m=8 and 12, W s =0.25μm, the simulation results of its transverse component field distribution are shown in Figure 5 (m=8) and Image 6 (m=12).

Embodiment 2

[0020] In this embodiment, it is to realize as figure 2 Anti-resonant reflective spider web hollow core fiber with the structure shown. Its parameter is n 1 = 1 (air), n 2 =1.49(PMMA),d 1 = 1.50 μm, d 2 =2.266μm, Λ=3.766μm, r 0 =10μm, N=4, m=8, W s =0.30μm and 0.567μm, the simulation results of the transverse component field distribution are shown in Figure 8 (W s = 0.30μm) and Figure 9 (W s = 0.567um).

[0021] Except for the above two embodiments, the spider web hollow-core optical fiber structure proposed by the present invention is suitable for various Bragg hollow-core optical fibers and other optical fibers with reflective characteristics formed by two layers of high and low refractive index materials. This optical fiber structure is suitable for a wide variety of materials, such as plastics, multi-component glasses, various composite materials, and various media. Its manufacturing process is related to the materials used to form the spider web-shaped hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com