Middle voltage electromotor cutting wave dual DSP digital speed adjusting system for IGBT reverser

A speed regulation system, digital speed regulation technology, applied in the direction of AC motor control, control system, electrical components, etc., can solve the problems of reliability reduction, boost chopper damage, high voltage generated in the rotor circuit, etc., to avoid interference and Coupling, easy to use and reliable, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

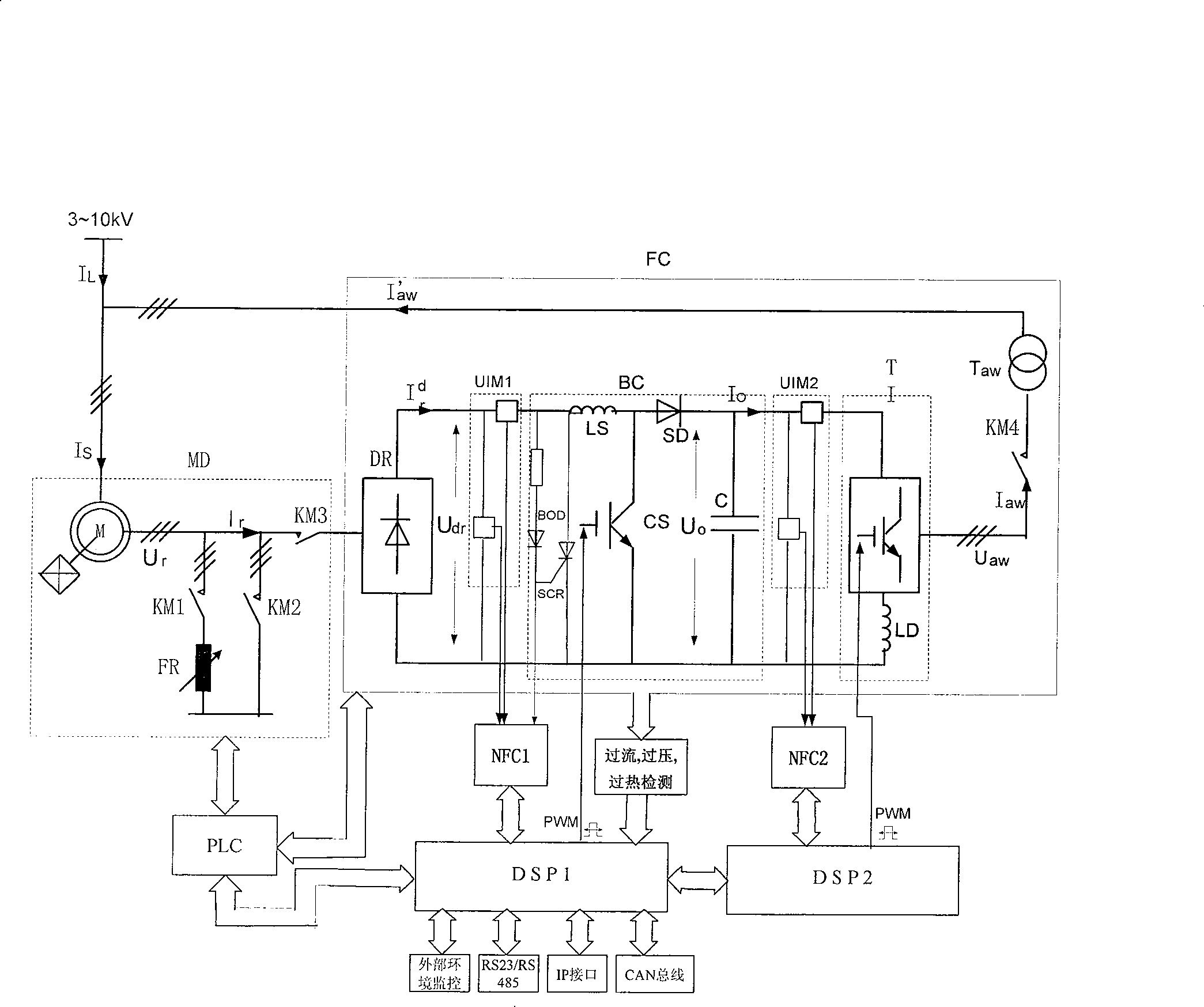

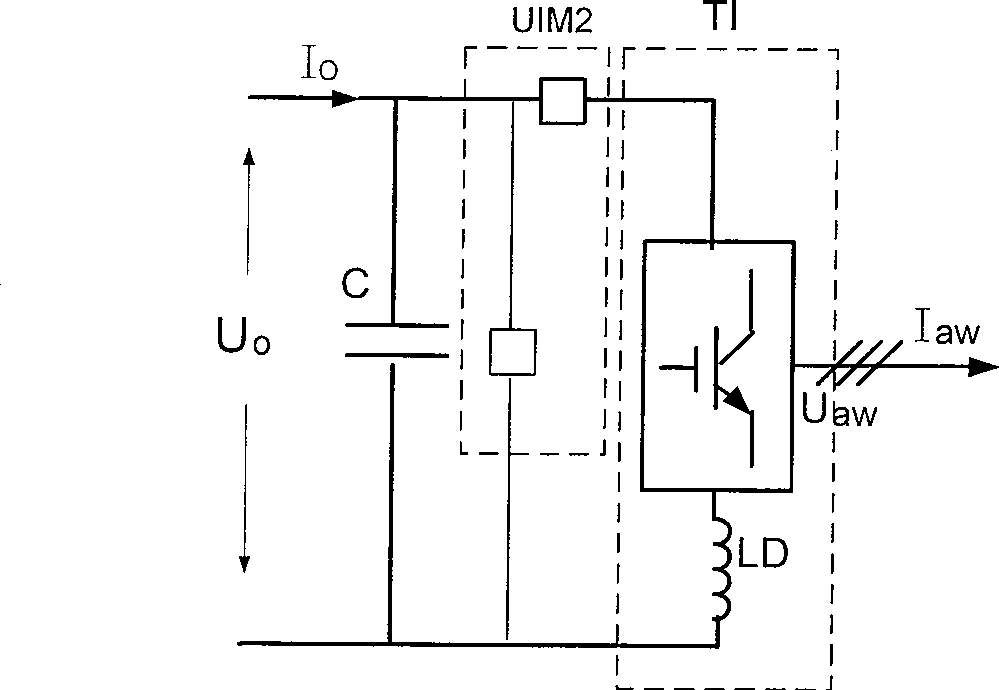

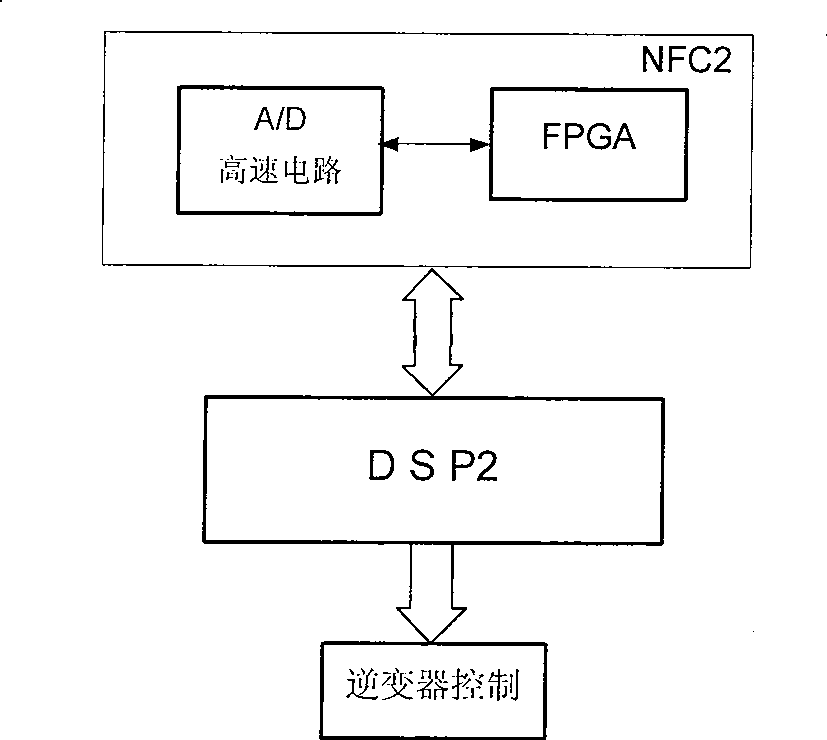

[0046] IGBT inverter medium voltage motor chopping type double DSP digital speed regulation system of the present invention, refer to figure 1 , MD is the motor system, including the motor M and its starter, control switch and power distribution and other auxiliary equipment. The speed control system FC includes the chopper type speed control main circuit using IGBT inverter and the digital intelligent control part of double DSP. In the main circuit, the uncontrollable rectifier DR in the speed control system FC is connected to the rotor winding through the brush and slip ring of the motor (KM1 and KM2 are disconnected during normal operation, and KM3 is closed), and the IGBT inverter TI is connected to the power grid through the transformer TAW . BC in the speed control system FC is a step-up chopper (composed of LS, SD, CS, C, BOD, and SCR), FR is a frequency-sensitive rheostat starter (or variable water resistance starter), KM1, KM2 and KM3 are three-phase contactors. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com