Method for preparing internal mold release agent for pulling and extruding glass fiber section bar

A technology for glass fiber reinforced plastic profiles and internal mold release agent, which is applied to the preparation field of internal mold release agent, can solve the problems of air bubbles, difficult operation control, color change, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method for an internal mold release agent for pultruded FRP profiles, comprising the steps of:

[0025] 1) Weigh the high-carbon fatty alcohol and phosphorus oxychloride according to the molar ratio of high-carbon fatty alcohol and phosphorus oxychloride as 5.0:1.0, and set aside; the high-carbon fatty alcohol is n-octanol, and the described trichloro Phosphate is analytically pure, with a purity greater than 99% by weight;

[0026] 2) In a four-necked flask equipped with a stirrer, a condenser, and a thermometer, add high-carbon aliphatic alcohol, put the four-necked flask into an ice-water bath, and pass nitrogen protection into the four-necked flask, and start stirring;

[0027] 3) When the temperature of the four-neck flask is lower than 5°C, slowly add phosphorus oxychloride to the high-carbon fatty alcohol through the dropping funnel, and keep stirring while adding, and control the adding speed to 35-45 drops / minute to keep the reaction When the tem...

Embodiment 2

[0030] Embodiment 2: The preparation method is the same as in Example 1, and n-octanol is replaced with a monohydric alcohol mixture containing C8-C12 range (such as the mixture of n-decyl alcohol and lauryl alcohol, and the moles of n-decyl alcohol and lauryl alcohol respectively account for high-carbon fats. 1 / 2 of alcohol). The test results of its basic physical properties are shown in Table 1.

Embodiment 3

[0031] Embodiment 3: The preparation method is the same as that of Embodiment 1. After raising the temperature to 70° C., the absolute pressure of the vacuum degree control system is increased from 5KPa to 3KPa. The test results of its basic physical properties are shown in Table 1.

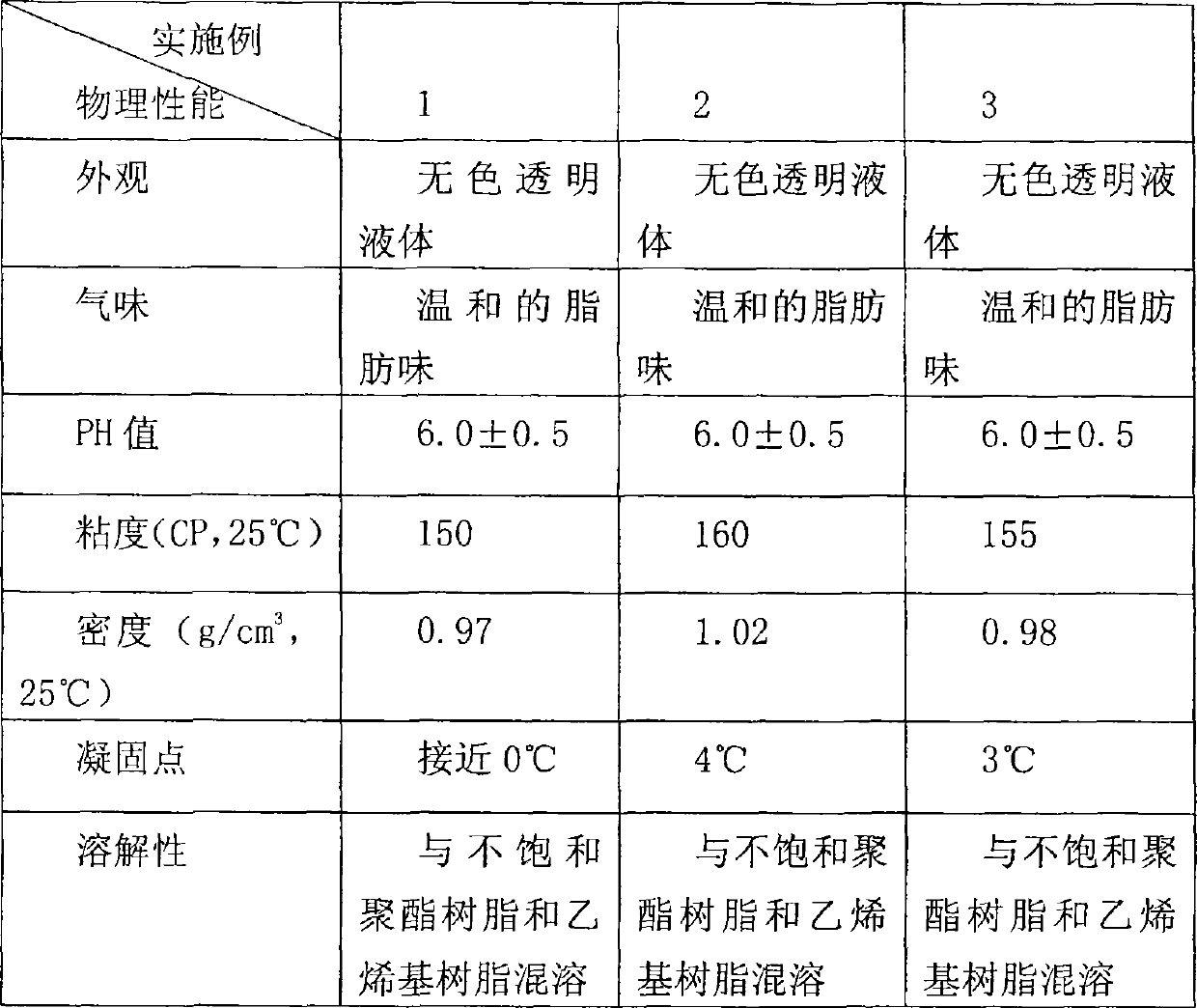

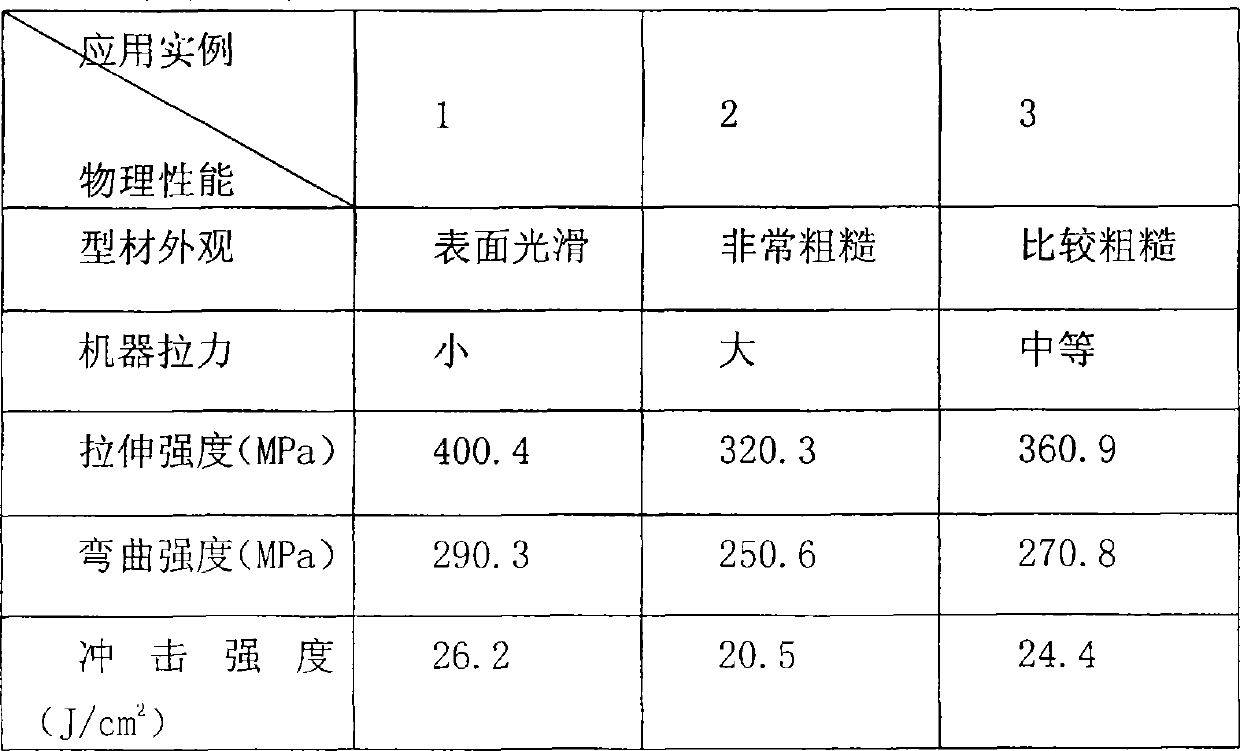

[0032] Table 1, Basic physical performance test results

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com