Rigid tension control system for conveyer belt coating production line

A tension control and production line technology, applied in the direction of belts, other household appliances, household appliances, etc., can solve the problems of unstable back pressure of the tension roller, large fluctuation of the output pressure of the air source air compressor, no precision, etc., to achieve accuracy High, high degree of automation, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

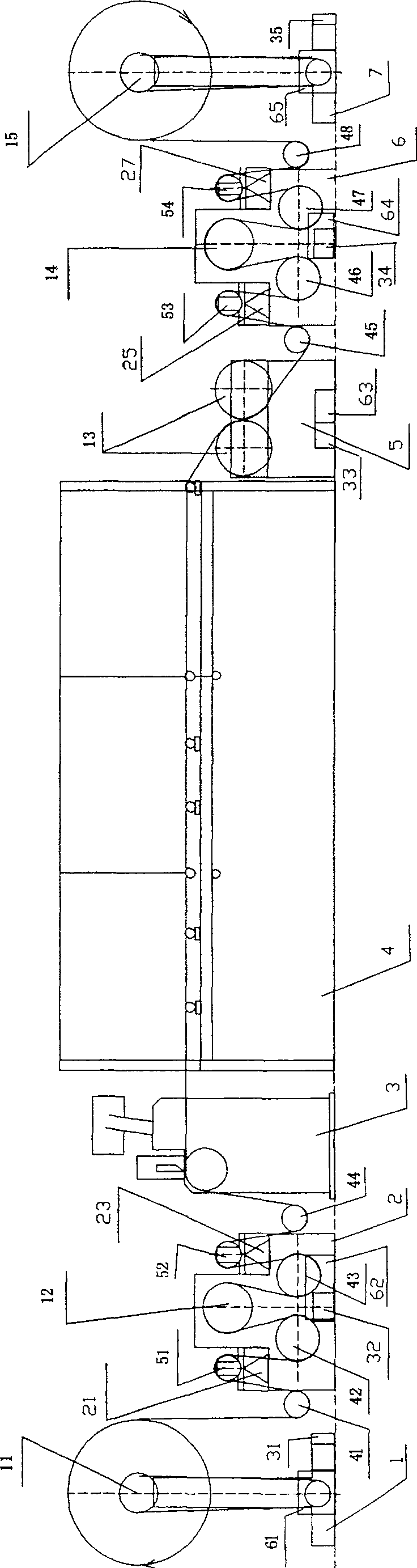

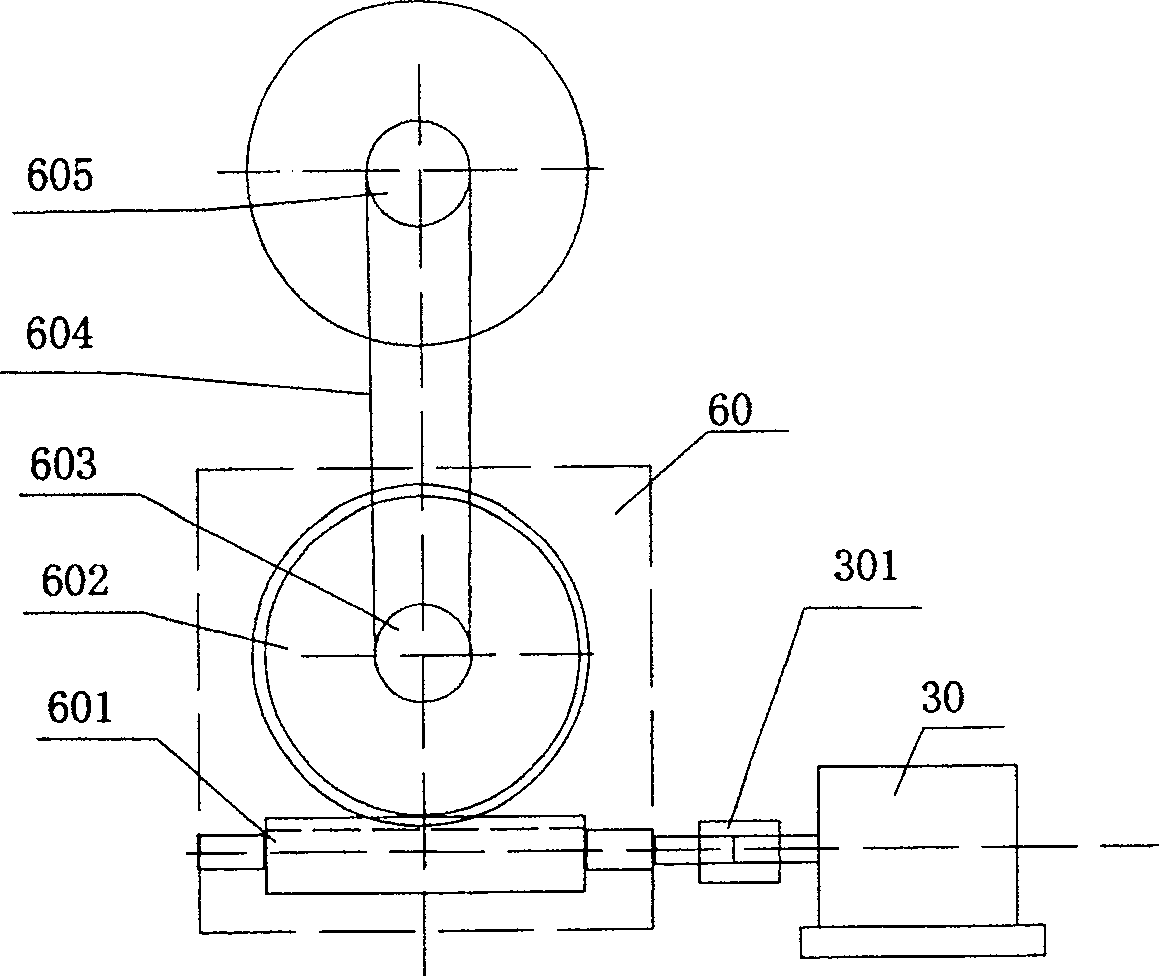

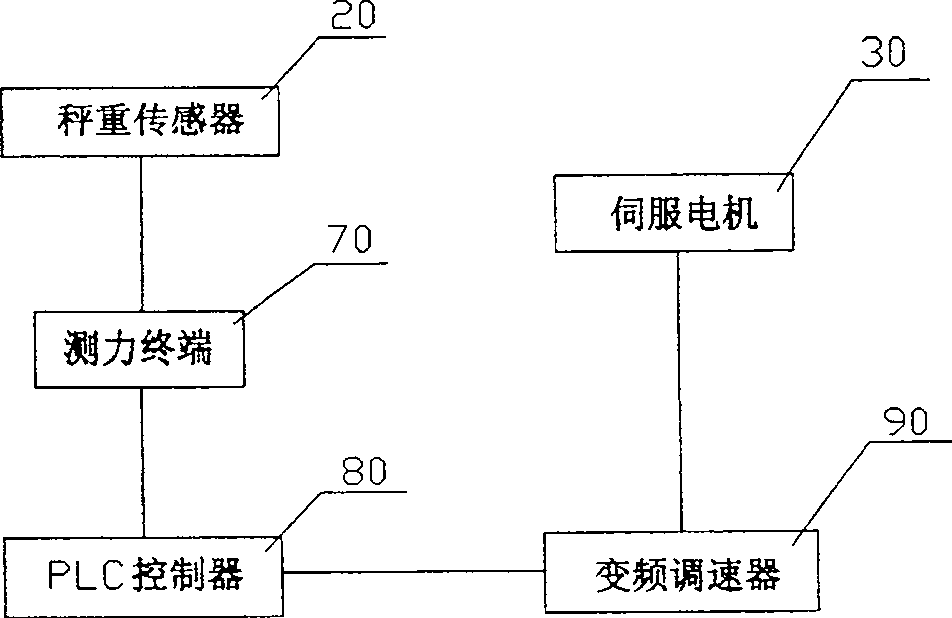

[0019] Such as figure 1 As shown, a rigid tension control system for a conveyor belt coating production line includes an unwinding machine 1, an unwinding tractor 2, a coating machine 3, a heating device 4, a laminating machine 5, a winding tractor 6, and a winding machine 7. Five reduction boxes (61, 62, 63, 64, 65), five servo motors (31, 32, 33, 34, 35), eight transition rollers (41, 42, 43, 44, 45 . The force measuring terminal and the programmable controller connected with the heavy sensor, and five frequency conversion speed regulators connected with the programmable controller. Wherein each group of weighing sensors includes two weighing sensors, and the servo motor drives the unwinding machine 1, the unwinding tractor 2, the laminating machine 5 and the retracting machine respectively through the reduction box (61, 62, 63, 64, 65). Roll pulli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com