Ferritic stainless steel containing rare earth element yttrium for solid-oxide fuel battery

A technology of solid oxides and rare earth elements, applied in fuel cells, circuits, electrical components, etc., can solve the problems of unreliable resistance data, inability to ensure compactness, and inability to meet SOFC performance requirements, etc., to achieve low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments.

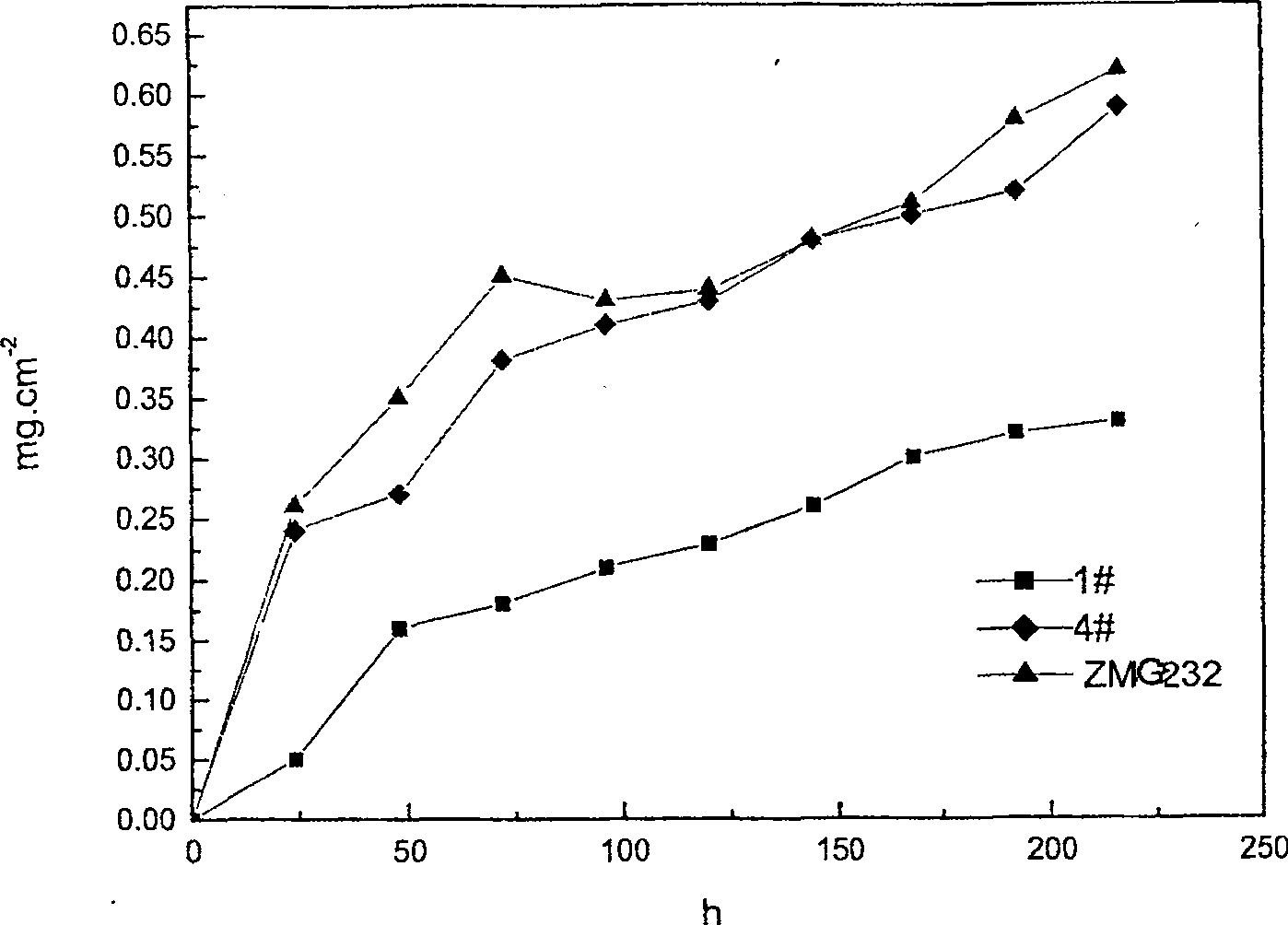

[0021]Ferritic stainless steel containing the above-mentioned alloying elements is refined into a 0.5kg ingot by arc melting, subjected to homogenization heat treatment at 1200°C for 24 hours, and heat treatment at 800°C for 1 hour. Obtain a single ferritic stainless steel, the mass percentage of its alloy elements is as follows: Y 0.04%~0.08%, C<0.03%, Mn 0.40%~1.00%, Ni 0.20%~0.26%, Cr19.00%~24.00%, Mo1.00%~2.00%, W 0.05%~0.10%, Si 0.02%~0.05%, P<0.04%, S<0.03%, and the balance Fe. In Table 1, the element compositions of several specific examples of the present invention are given.

[0022] Table 1

[0023] implement

example

C

Y

mn

Ni

Cr

Mo

W

Si

P

S 1# 0.02 0.08 1.00 0.20 22.00 2.00 0.09 0.05 0.03 0.02 2# 0.02 0.06 0.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com