Cut-off wall slurry material and wall building technique

A technology for anti-seepage walls and walls, applied in sheet pile walls, solid waste management, infrastructure engineering, etc., can solve the problems of self-setting mortar anti-seepage walls that are not convenient for on-site construction and poor impermeability of wall materials, and achieve Strong controllability of coagulation time, good shear thinning property, and the effect of ensuring flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The composition and content of non-dispersible low-solid high-quality bentonite mud for wall protection are (unit: kg / m 3 ): Bentonite 70, Soda Ash 2.5, Hydrolyzed Polyacrylamide 0.16, Hydrolyzed Polyacrylonitrile 1.5, Water 940.

[0018] The components and content of the original mortar for curing are (according to the production of 1m 3 Calculation of cut-off wall volume, unit kg / m 3 ): No. 425 ordinary Portland cement 240, sand 120, fly ash 35, water glass 20, naphthalene sulfonate condensation polymer 1.2, aluminum sulfate 0.3, water 108.

[0019] Use 0.6m 3 The retaining wall with mud and 1m 3 1m 3 anti-seepage wall. The specific manufacturing steps are as follows: during the excavation process of the unit groove section of the anti-seepage wall, inject mud for wall protection into the groove; during the construction period of the unit groove section, gradually add the original mortar for curing to the mud in the groove During the excavation operation of the ...

Embodiment 2

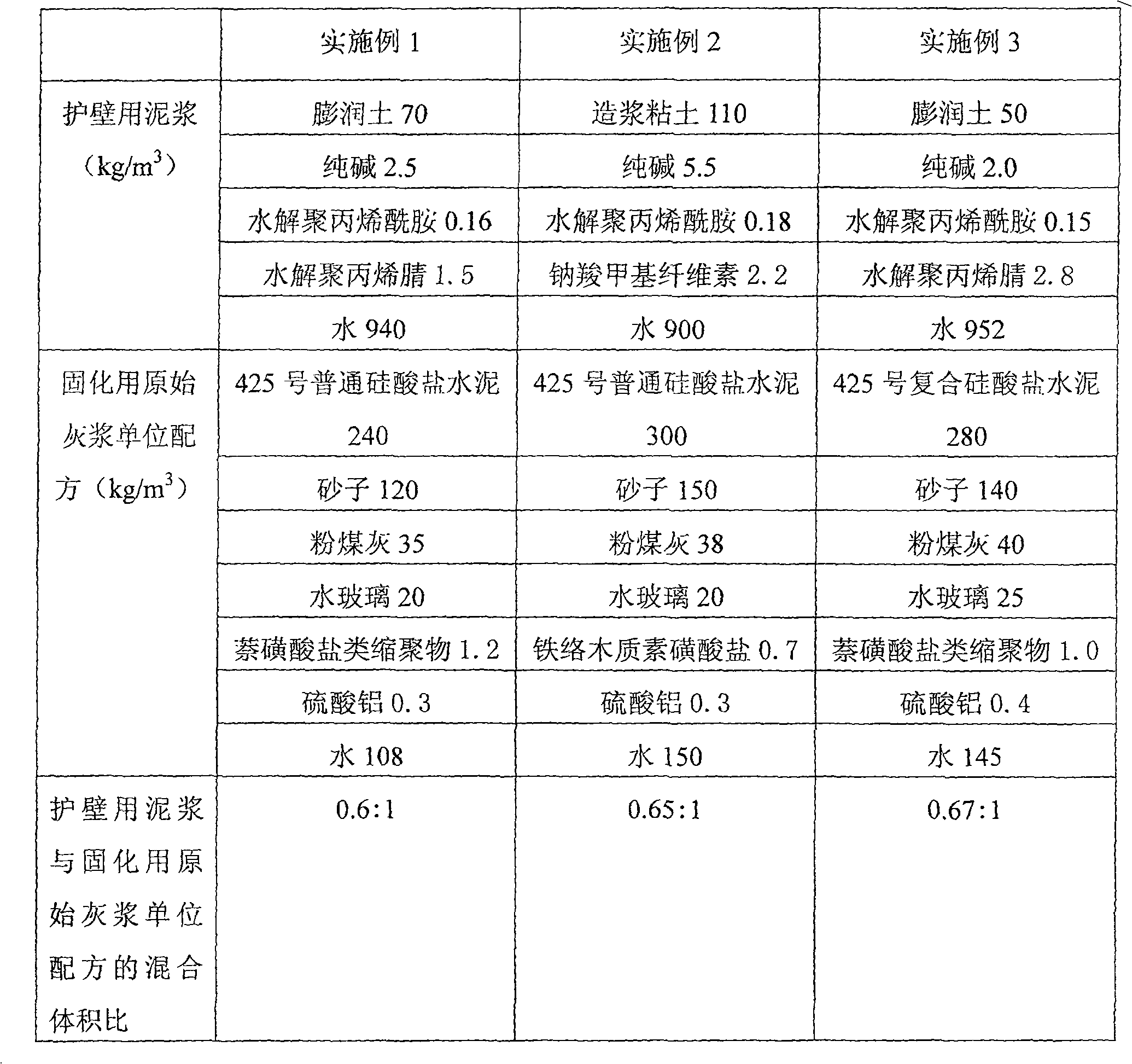

[0023] The components and consumption of the mud for retaining wall and the original mortar for curing are shown in Table 1. The wall-building process is basically the same as in Example 1, except that 10 kg of water glass is included when mixing for the first time, and the remaining 10 kg of water glass is mixed for the second time. join in. The parameters of the mixture are listed in Table 2.

Embodiment 3

[0025] The components and consumptions of mud for wall protection and original mortar for curing are shown in Table 1. The wall building process is basically the same as in Example 1, except that 10 kg of water glass is included when mixing for the first time, and the remaining 15 kg of water glass is mixed for the second time. join in. The parameters of the mixture are listed in Table 2.

[0026] The wall thickness of the solidified mortar anti-seepage wall of the present invention is generally 15-150 cm, the bottom of which should be embedded in the bedrock or impermeable layer for 0.5-1.0 m, and the depth of the wall can be as deep as 60 m.

[0027] Table 1

[0028]

[0029] Table 2

[0030] Example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com