Compound shade ultra-distinguish differential confocal measurement method and device

A differential confocal, measuring device technology, applied in the field of ultra-precision measurement, can solve the problems of low sensitivity and only applicable to the axial response signal measurement, achieve linear range expansion, improve signal-to-noise ratio, and suppress common mode noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

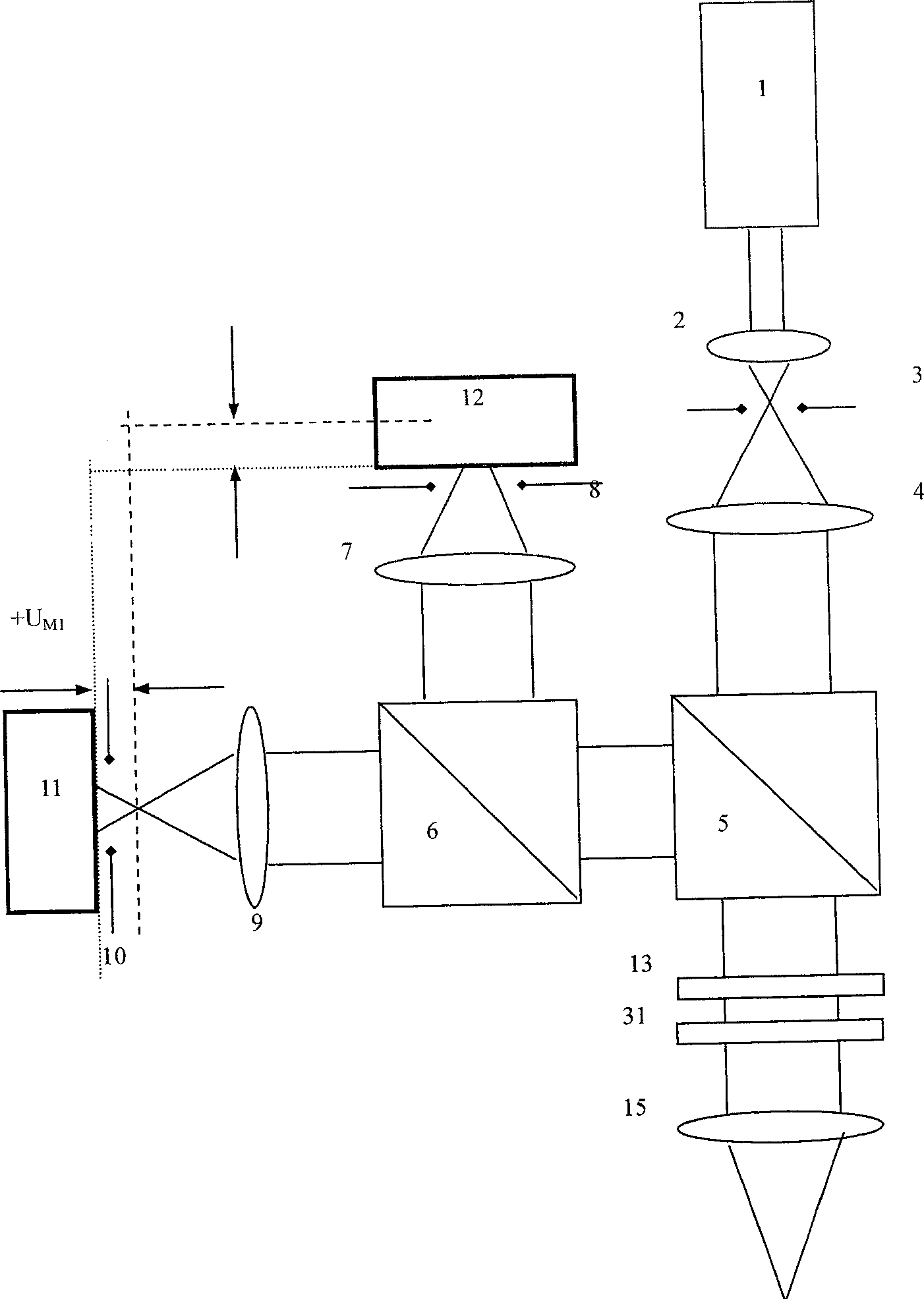

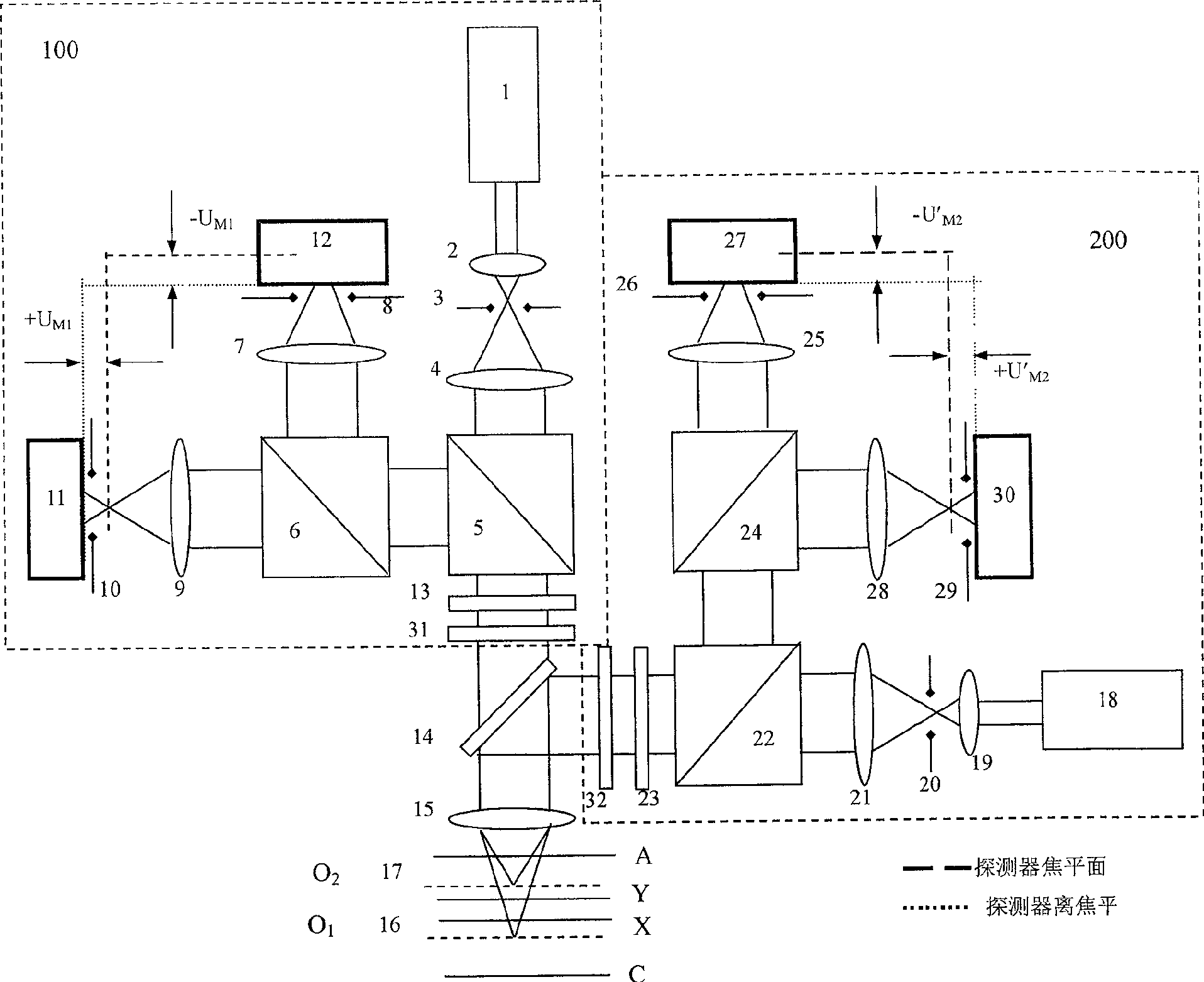

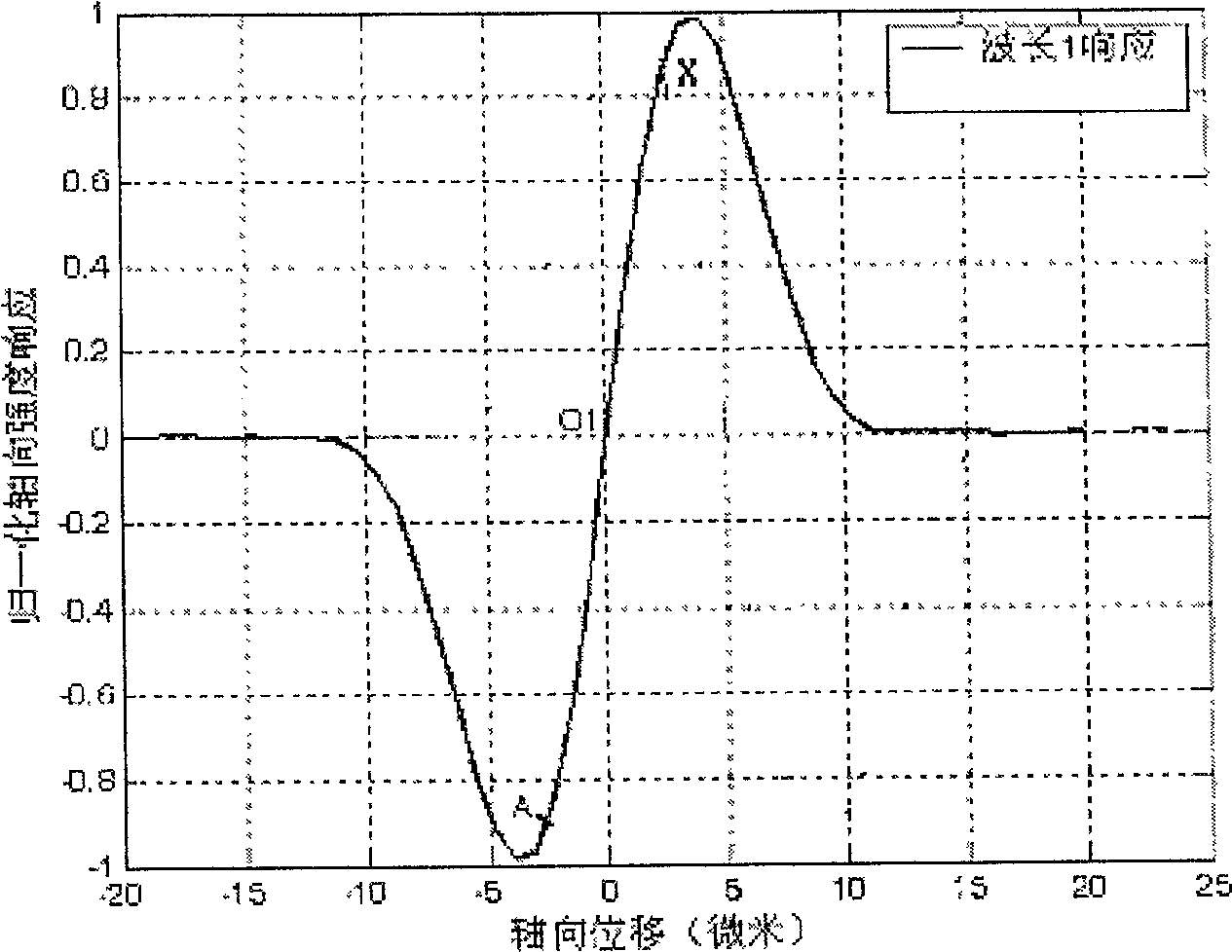

[0022] refer to image 3 , the polychromatic super-resolution differential confocal measurement device provided in the first specific embodiment of the present invention includes a first super-resolution differential confocal measurement device 100, and the first super-resolution differential confocal measurement device 100 includes a first Laser 1, the first laser emits the first wavelength λ 1 The light of the first wavelength is collimated through the first collimating and focusing objective lens 2, the first pinhole 3 and the first collimating and focusing objective lens 4, and then divided into two beams of polarized light by the first polarizing beam splitter 5, One beam of polarized light is split by the first beam splitter 6, and one beam passes through the first detection focusing objective lens 7 and the second pinhole 8, and then is received by the first photodetector 12 located near the focal plane, and the other beam passes through the first detection focusing obj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com