Horizontal flame gun

A gunning machine and flame technology, applied in lining repair, etc., can solve the problems of low degree of mechanization, easy adhesion of repair material to the inner wall of steel pipe, rapid cooling and cracking of refractory lining, etc., and achieve high degree of mechanization, good remote control performance, strong resistance The effect of high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

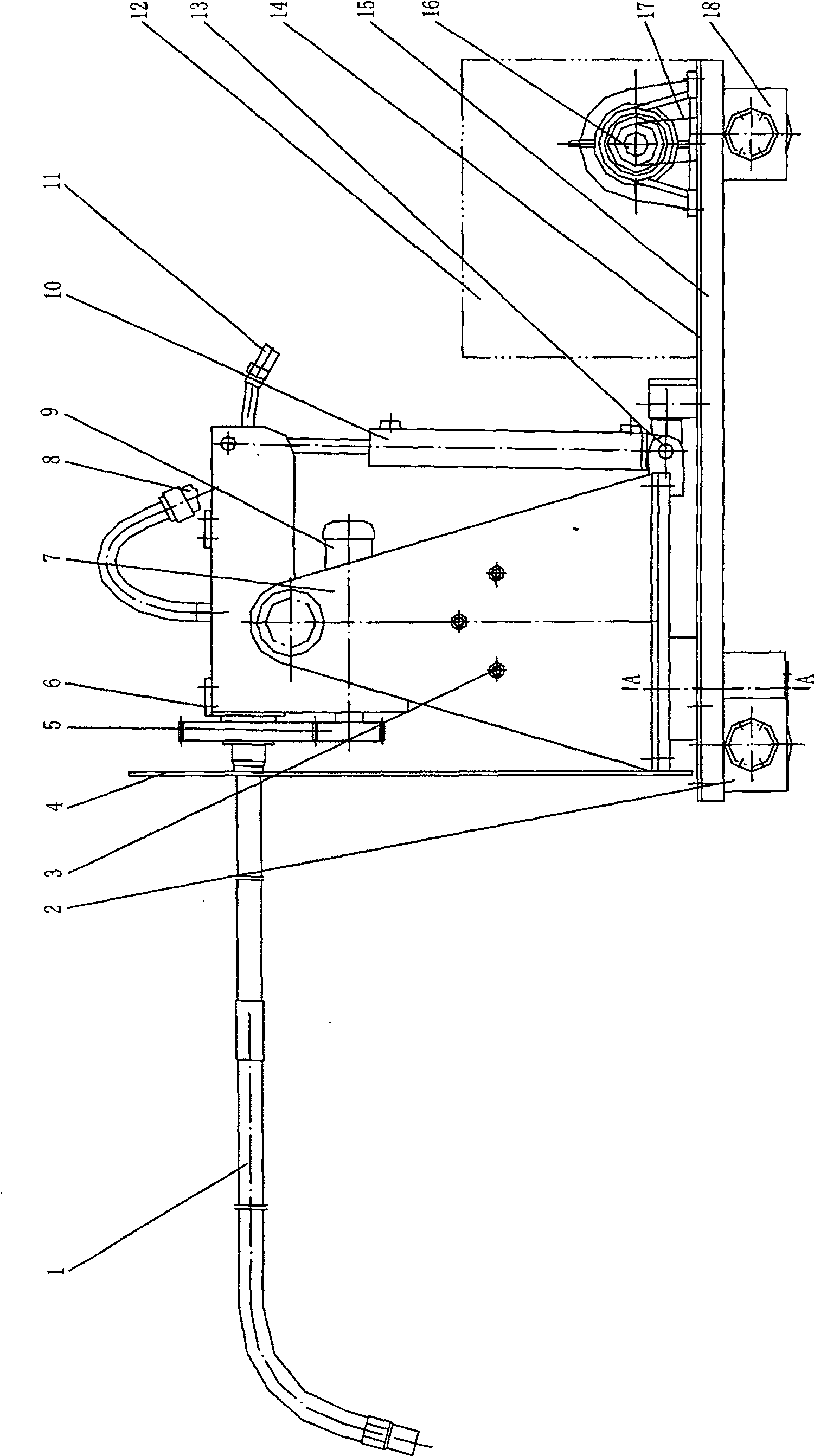

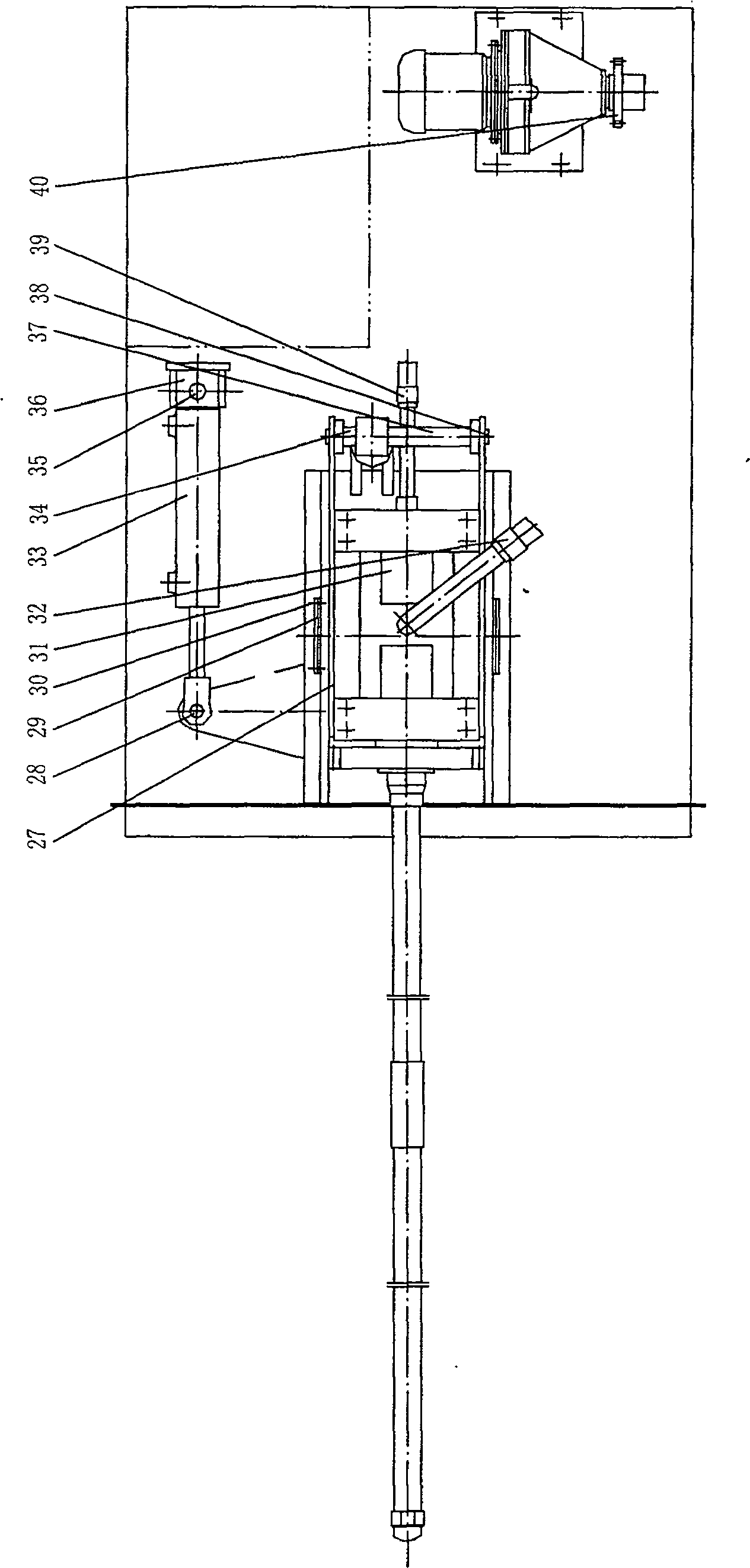

[0036] The structure or action process of the horizontal flame gunning machine of the present invention will be described in conjunction with the drawings and embodiments.

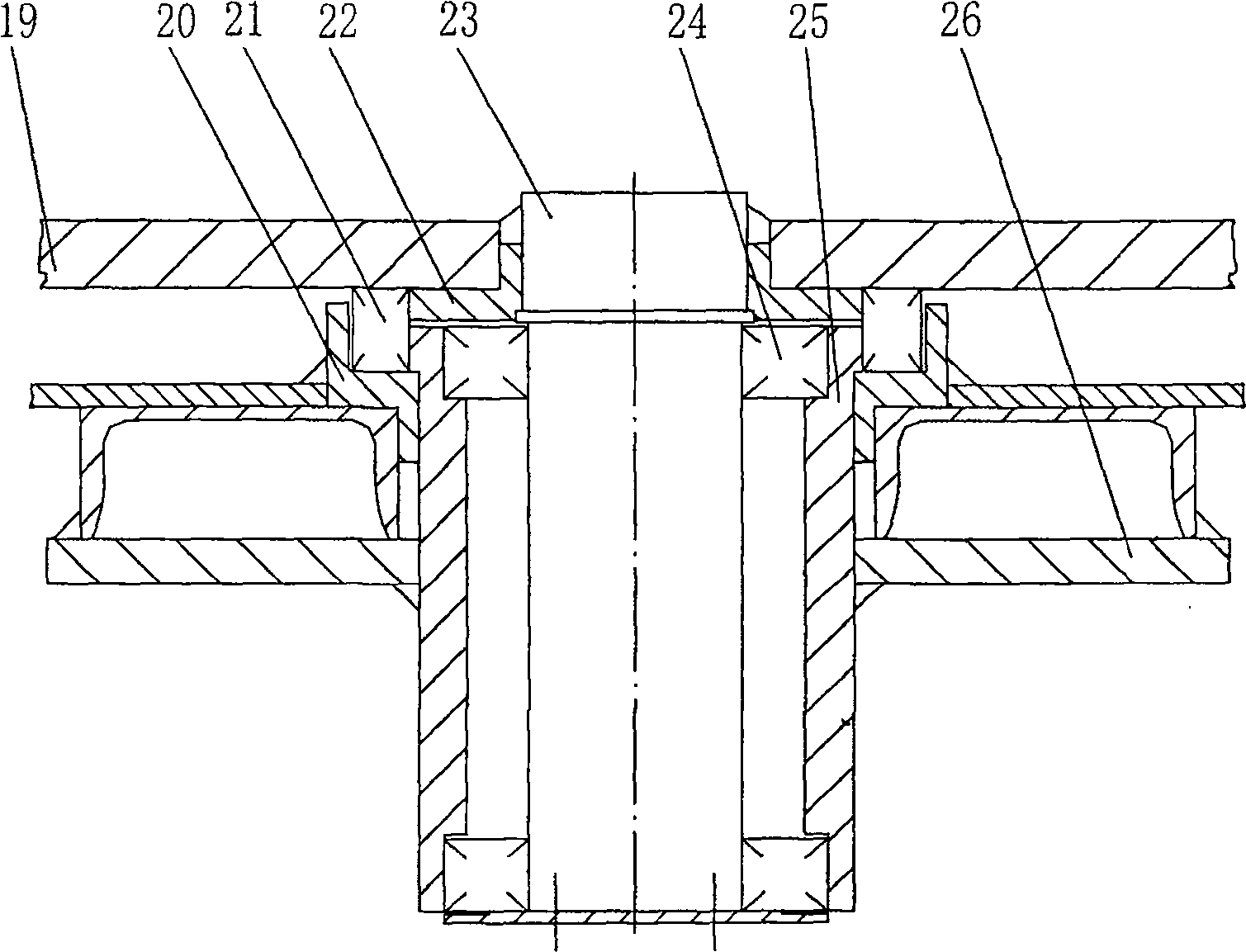

[0037] The structural principle of the horizontal flame gunning machine of the present invention is to provide oxygen and gas mixed with fluidized solid powder gunning material from the outside, and send them to the horizontal flame gunning machine through two pipelines to rotate coaxially. Combiner, in the coaxial rotary synthesizer, it can be transformed into a rotating coaxial casing to be transported into the double-layer sandblasting casing, the gas is transported to be fluidized solid powder gunning material in the inner layer of the double-layer sandblasting casing, and the oxygen is in the outer layer . The double-layer sandblasting casing with an appropriate length is inserted into the hearth of a horizontal industrial furnace through the trolley movement of the horizontal flame gunning machine. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com