Continuous growing multilayer cube-texture insulating layer on metallic substrate and preparation method thereof

A technology of metal baseband and cubic texture, which is applied in metal material coating process, coating, ion implantation plating, etc., can solve the problems of low sputtering yield and slow film growth rate, and achieve sputtering yield High, slow film growth rate, fast growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

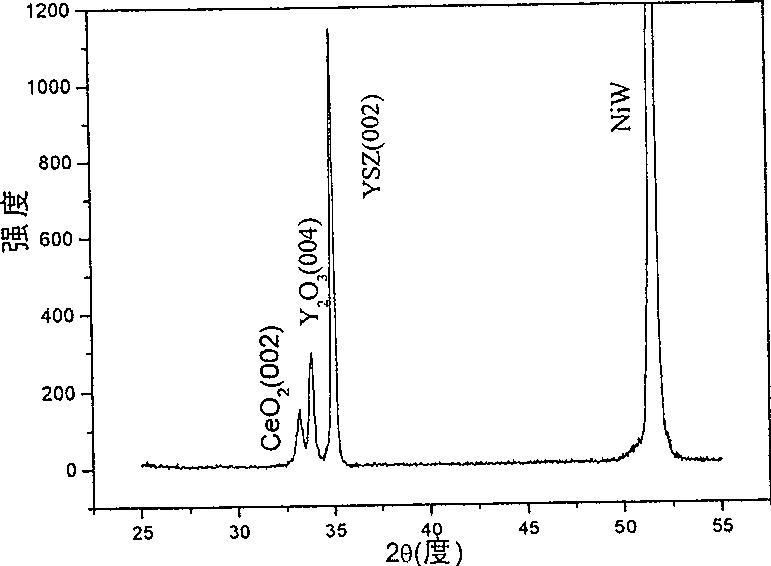

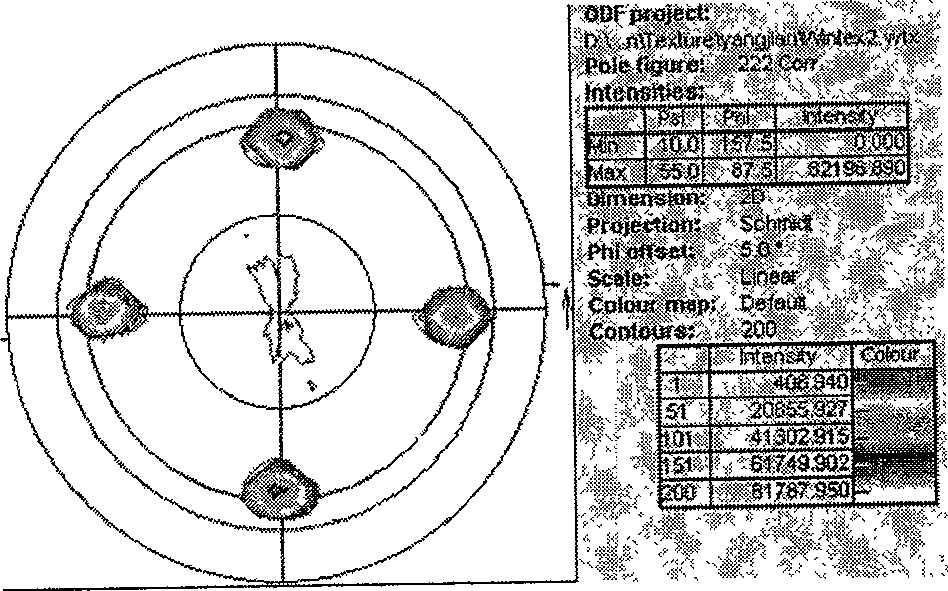

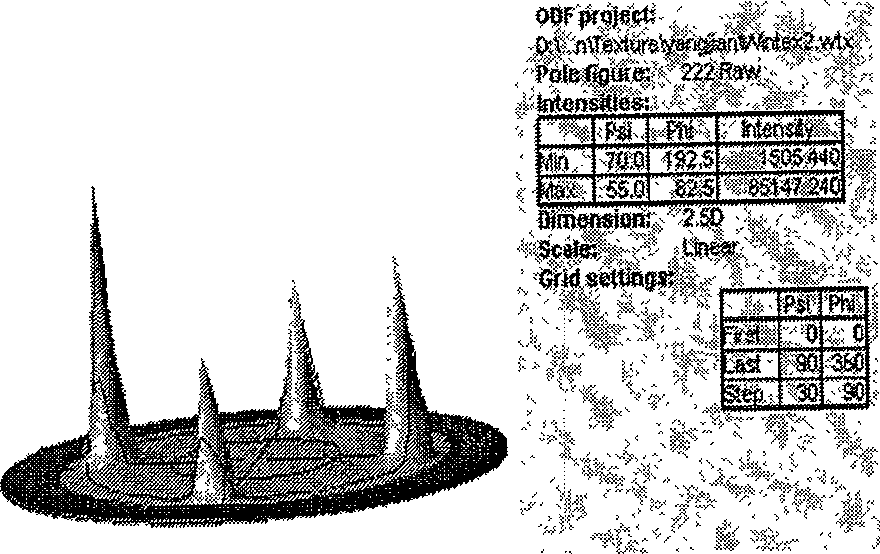

[0058] Connect the front and rear ends of the metal base tape with cubic texture to the leader tape and clean it. Wrap the cleaned metal base tape and leader tape on the unwinding and take-up reels, place them in a vacuum chamber, and place the leader part in the deposition area. Vacuum until the back vacuum of the cavity is less than or equal to 5×10 -4 Pa; heat the metal substrate to 500°C, and after reaching the required temperature for 30 minutes, fill the chamber with argon to a pressure of 1×10 -1 Pa.

[0059] Taking Y metal as the sputtering target, adopting the DC magnetron sputtering deposition method, the injection power is 320W, and the target base distance is 120mm, and the pre-sputtering is started. After 20 minutes of pre-sputtering, water vapor was introduced to control the water content in the deposition chamber at 1×10 -3 Pa, and adjust the pressure in the deposition chamber to 1Pa, and start the formal sputtering deposition. After the official sputtering ...

Embodiment 2

[0075] Connect the front and rear ends of the metal base tape with cubic texture to the leader tape and clean it. Wrap the cleaned metal base tape and leader tape on the unwinding and take-up reels, place them in a vacuum chamber, and place the leader part in the deposition area. Vacuum until the back vacuum of the cavity is less than or equal to 5×10 -4 Pa; heat the metal substrate to 700°C, and after reaching the required temperature for 30 minutes, fill the chamber with argon to a pressure of 5×10 -1 Pa.

[0076] Taking Y metal as the sputtering target material, using the DC magnetron sputtering deposition method, the injection power is 350W, and the target base distance is 60mm, and the pre-sputtering is started. After 20 minutes of pre-sputtering, water vapor was introduced to control the water content in the deposition chamber at 8×10 -3 Pa, and adjust the pressure in the deposition chamber to 2Pa, and start the formal sputtering deposition. After the official sputte...

Embodiment 3

[0083] Connect the front and rear ends of the metal base tape with cubic texture to the leader tape and clean it. Wrap the cleaned metal base tape and leader tape on the unwinding and take-up reels, place them in a vacuum chamber, and place the leader part in the deposition area. Vacuum until the back vacuum of the cavity is less than or equal to 5×10 -4 Pa; heat the metal substrate to 800°C, and after reaching the required temperature for 30 minutes, fill the chamber with argon to a pressure of 8×10 -1 Pa.

[0084] Taking Y metal as the sputtering target material, using the DC magnetron sputtering deposition method, the injection power is 350W, and the target base distance is 80mm, and the pre-sputtering is started. After 20 minutes of pre-sputtering, water vapor was introduced to control the water content in the deposition chamber at 7×10 -3 Pa, and adjust the pressure in the deposition chamber to 5Pa, and start the formal sputtering deposition. After the official sputte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com