Method for growing cube-texture yttrium-stabile zirconium dioxide film

A zirconium dioxide film, cubic texture technology, applied in coating, metal material coating process, ion implantation plating and other directions, can solve the problems of slow film growth rate, low sputtering yield, etc. The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The metal substrate with a cubic texture oxide isolation layer is ultrasonically cleaned and degreasing with acetone, leaving no water marks or stains on the surface. Put the sample into the magnetron sputtering deposition chamber and evacuate until the background vacuum is less than 5×10 -4 Pa. The substrate is heated to 800°C and filled with argon to 2×10 -1 Pa; Using metal YSZ wafer as the sputtering target, using DC magnetron sputtering deposition technology, sputtering power 320W, target base distance 120mm, start pre-sputtering; 20 minutes later, water vapor into the cavity to make the cavity Water vapor partial pressure is 1×10 -2 Pa, control the total pressure in the deposition chamber to 2 Pa, and start the formal sputtering deposition. After the deposition, the YSZ film is obtained.

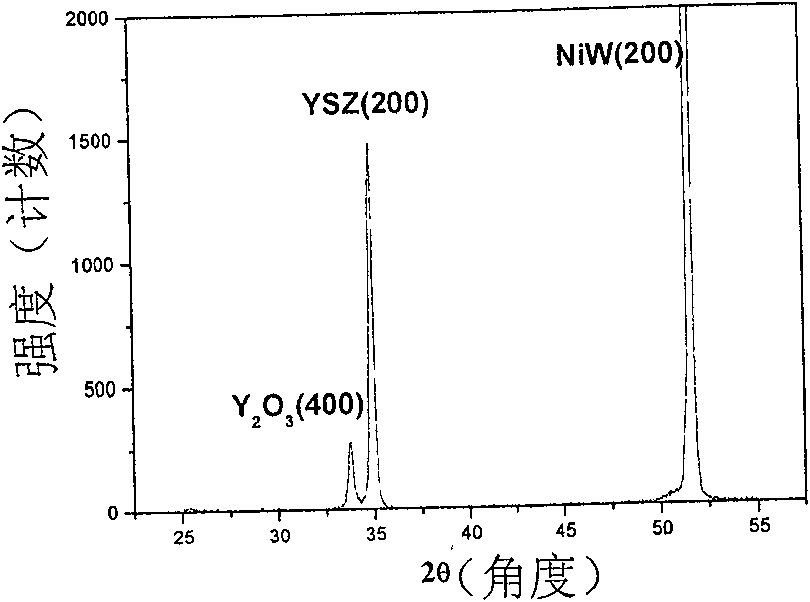

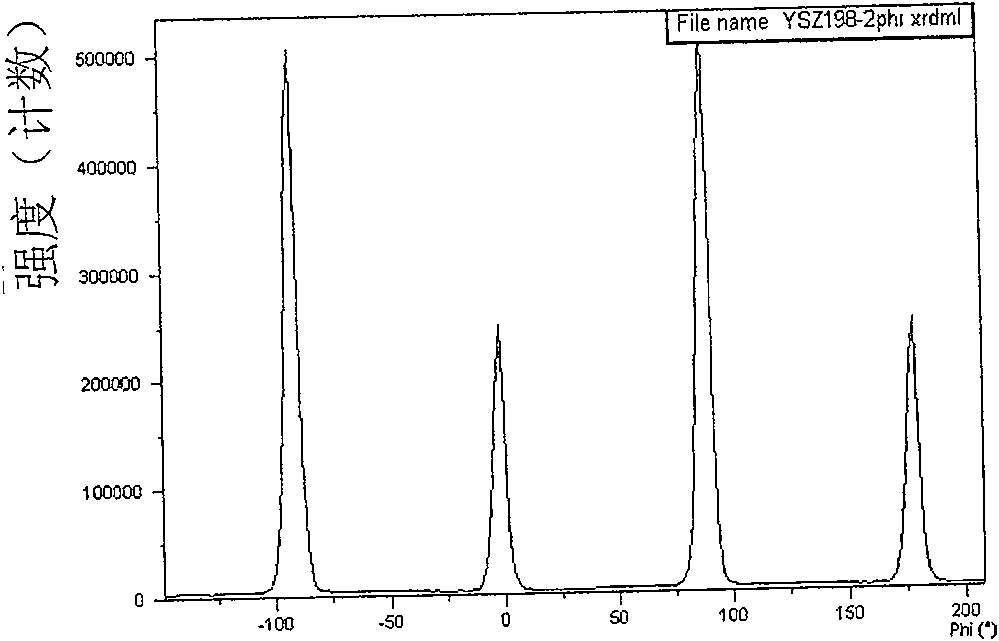

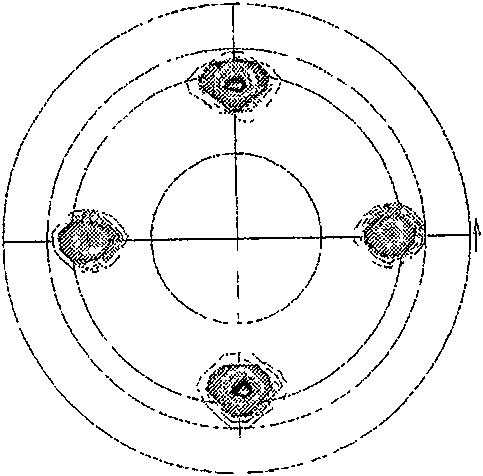

[0036] figure 1 In order to adopt the method of the present invention, 2 O 3 Cubic texture YSZX-light diffraction θ-2θ scanning grown on the metal NiW substrate of the isolation la...

Embodiment 2

[0038]The metal substrate with a cubic texture oxide isolation layer is ultrasonically cleaned and degreasing with acetone, leaving no water marks or stains on the surface. Put the sample into the magnetron sputtering deposition chamber and evacuate until the background vacuum is less than 5×10 -4 Pa. The substrate is heated to 620℃ and filled with argon to 1×10 -1 Pa; Using metal YSZ wafer as the sputtering target, using DC magnetron sputtering deposition technology, sputtering power 400W, target base distance 150mm, start pre-sputtering; 20 minutes later, water vapor is injected into the cavity to make the cavity Water vapor partial pressure is 1.5×10 -2 Pa, control the total pressure in the deposition chamber to 1 Pa, and start the formal sputtering deposition. After the deposition, the YSZ film is obtained.

Embodiment 3

[0040] The metal substrate with cubic texture is ultrasonically cleaned with acetone to remove oil without leaving water marks and stains on the surface. Put the sample into the magnetron sputtering deposition chamber and evacuate until the background vacuum is less than 5×10 -4 Pa. The substrate is heated to 650℃ and filled with argon gas to 8×10 -1 Pa; Using metal YSZ wafer as the sputtering target material, using DC magnetron sputtering deposition technology, sputtering power 120W, target base distance 60mm, start pre-sputtering; 20 minutes later, water vapor is injected into the cavity to make the cavity Water vapor partial pressure is 1×10 -3 Pa, control the total pressure in the deposition chamber to 5 Pa, and start the formal sputtering deposition. After the deposition, the YSZ film is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com